Method for preparing cyclic carbonate by utilizing combined catalysis of succinimide and halide

A technology of succinimide and cyclic carbonate, applied in the field of catalytic synthesis, can solve problems such as harsh reaction conditions, and achieve the effects of strong substrate adaptability, efficient synthesis and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-16

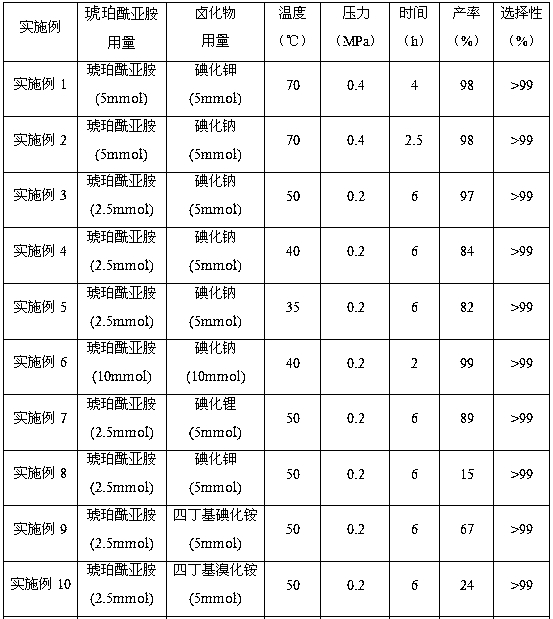

[0018] A method for preparing cyclic carbonates by combined catalysis of succinimide and halides, specifically: in a 100mL stainless steel autoclave, add a certain amount of succinimide and halides in sequence, and then quickly add propylene oxide (PO) 100mmol closed reactor, filled with CO at room temperature 2 After reaching a certain pressure, the temperature is controlled by the temperature controller to rise to a certain temperature, and the constant pressure reacts for a certain period of time. Cool to room temperature after the reaction, release excess CO slowly 2 , Distill the resulting liquid under reduced pressure to obtain the product propylene carbonate, and analyze the selectivity of the product by gas chromatography. The specific reaction conditions and reaction results of each embodiment are shown in Table 1.

[0019] Table 1 The results of the coupling reaction of carbon dioxide and propylene oxide catalyzed by different catalytic systems under different cond...

Embodiment 17-20

[0023] A method for preparing cyclic carbonates by combined catalysis of succinimide and halides, specifically: in a 100mL stainless steel autoclave, add 1 mmol each of succinimide and sodium iodide in sequence, and then quickly add epoxy compounds 20mmol, airtight reactor, filled with CO at room temperature 2 After reaching a pressure of 0.2 MPa, the temperature was controlled by a temperature controller to rise to 50°C, and the reaction was performed at constant pressure for a certain period of time. Cool to room temperature after the reaction, release excess CO slowly 2 , Pass the resulting product through the column to obtain the corresponding pure product, and analyze the selectivity of the product by gas chromatography. The specific reaction conditions and reaction results of each embodiment are shown in Table 2.

[0024] Table 2 The results of the coupling reaction between carbon dioxide and different epoxy compounds catalyzed by sodium iodide and succinimide

[0025...

Embodiment 21-25

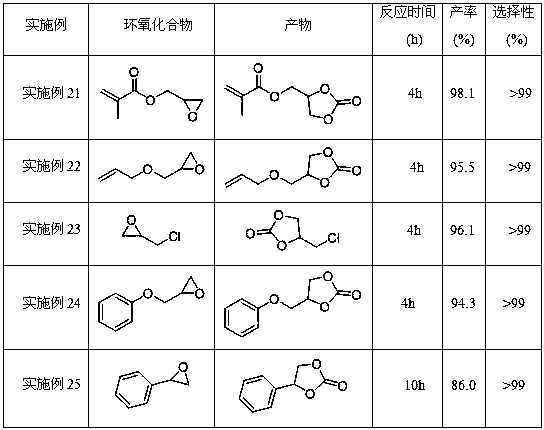

[0027] A kind of method that utilizes succinimide and halide to jointly catalyze and prepare the method for cyclic carbonate, specifically: in 100mL stainless steel autoclave, add succinimide and potassium iodide each 1mmol successively, then add epoxy compound 20mmol rapidly, Close the reactor and fill it with CO at room temperature 2 After the pressure reaches 0.4MPa, the temperature is controlled by the temperature controller to rise to 70°C, and the reaction takes place for a certain period of time. Cool to room temperature after the reaction, release excess CO slowly 2 , Pass the resulting product through the column to obtain the corresponding pure product, and analyze the selectivity of the product by gas chromatography. The specific reaction conditions and reaction results of each embodiment are shown in Table 3.

[0028] Table 3 The results of the coupling reaction between carbon dioxide and different epoxy compounds catalyzed by potassium iodide and succinimide

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com