Preparation method and application of graphene-wrapping fluorine-doped lithium titanate nanowire

A graphene-coated, lithium fluorotitanate technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve uneven mixing, uneven fluorine doping, difficult doping amount Determine and other issues to achieve the effect of low cost, uniform doping, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Weigh 24g NaOH and dissolve in 60mL deionized water, and weigh 0.6g industrialized TiO 2 Pour it into it and add 3mL of graphene oxide, stir at room temperature for 2h on a magnetic stirrer, then ultrasonicate for 2h, pour the mixture into a 100mL hydrothermal reactor and react in an oven at 200°C for 24h, then take out the reactant and wash it with deionized water several times, filtered and aged in dilute hydrochloric acid solution with pH 3 for 3h to obtain H 2 Ti 3 o 7 Nanowires.

[0059] Mix the obtained titanate nanowires with 50 mL of LiOH solution (0.5 mol / L), and add 0.05 g of NH 4 After F, pour them into an 80mL reactor, react at 150°C for 24h, take out, wash, filter and dry, and then sinter in an argon atmosphere furnace at 450°C for 3h to obtain graphene-coated fluorine-doped Li 4 Ti 5 o 12 Nanowires.

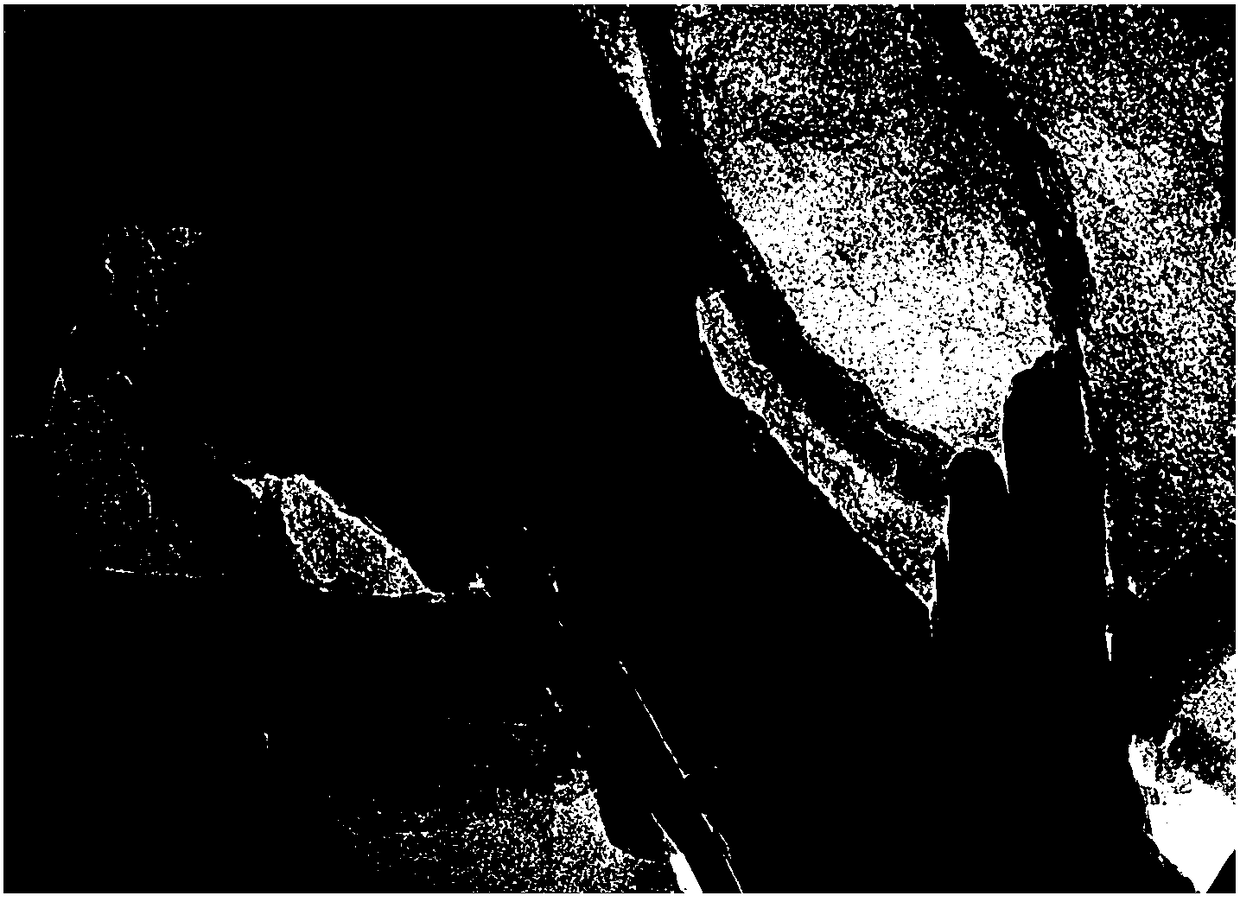

[0060] figure 1 It is the TEM picture made in Example 1. It can be seen from the figure that the lithium titanate nanowire material synthesized by th...

Embodiment 2

[0064] Weigh 24g NaOH and dissolve it in 60mL deionized water, weigh 1g industrialized TiO2 and pour it into it, add 3mL graphene oxide, stir at room temperature on a magnetic stirrer for 2h, then ultrasonicate for 2h, pour the mixture into a 100mL hydrothermal reaction kettle React in an oven at 180°C for 36 hours, then take out the reactant and wash it several times with deionized water, filter and age in a dilute hydrochloric acid solution with a pH of 3 for 3 hours to obtain H 2 Ti 3 o 7 Nanowires.

[0065] Mix the obtained titanate nanowires with 50 mL of LiOH solution (0.5 mol / L), and add 0.03 g of NH 4 After F, pour them into an 80mL reactor, react at 200°C for 36h, take out, wash, filter and dry, and then sinter in an argon atmosphere furnace at 450°C for 3h to obtain graphene-coated fluorine-doped Li 4 Ti 5 o 12 Nanowires.

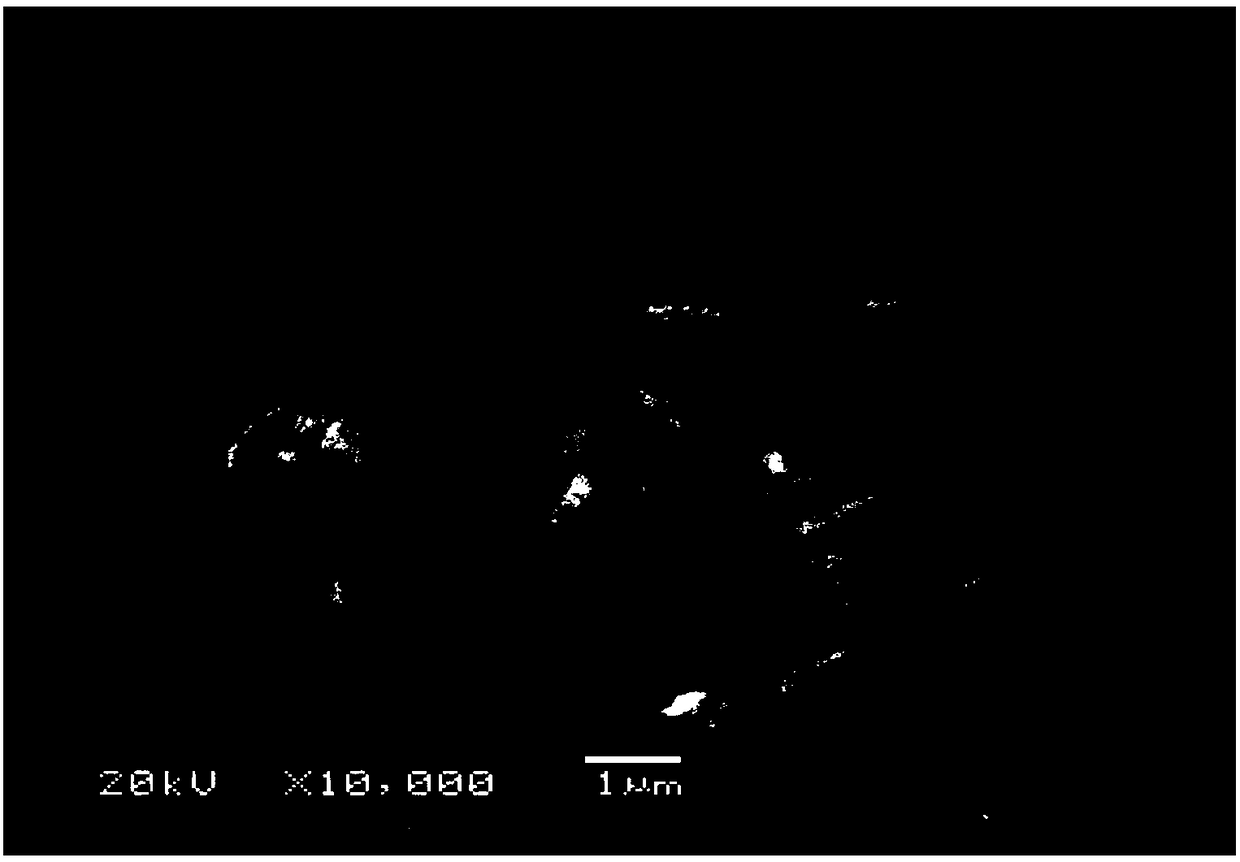

[0066] image 3 This is the SEM image of the graphene-coated lithium fluorotitanate nanowires synthesized in Example 2. It can be seen fro...

Embodiment 3

[0069] Weigh 30g NaOH and dissolve in 60mL deionized water, and weigh 0.6g industrialized TiO 2 Pour it into it and add 3mL of graphene oxide, stir at room temperature for 2h on a magnetic stirrer, then ultrasonicate for 2h, pour the mixture into a 100mL hydrothermal reaction kettle and react in an oven at 150°C for 48h, then take out the reactant and wash it with deionized water several times, filtered and aged in dilute hydrochloric acid solution with pH 3 for 4h to obtain H 2 Ti 3 o 7 Nanowires.

[0070] Mix the obtained titanate nanowires with 50mL of LiOH solution (0.5mol / L), add 0.035g of LiF and pour them into an 80mL reaction kettle together, react at 200°C for 36h, take out, wash, filter and dry, then place in argon Fluorine-doped Li 4 Ti 5 o 12 Nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com