Inner tube of pressure cooker

A pressure cooker and pot wall technology, applied in the field of pressure cookers, can solve the problems of increased production cost, increased production difficulty, deformation of the inner pot of the pressure cooker, etc., and achieves the effects of low cost, simple and reasonable structure design, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific example

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

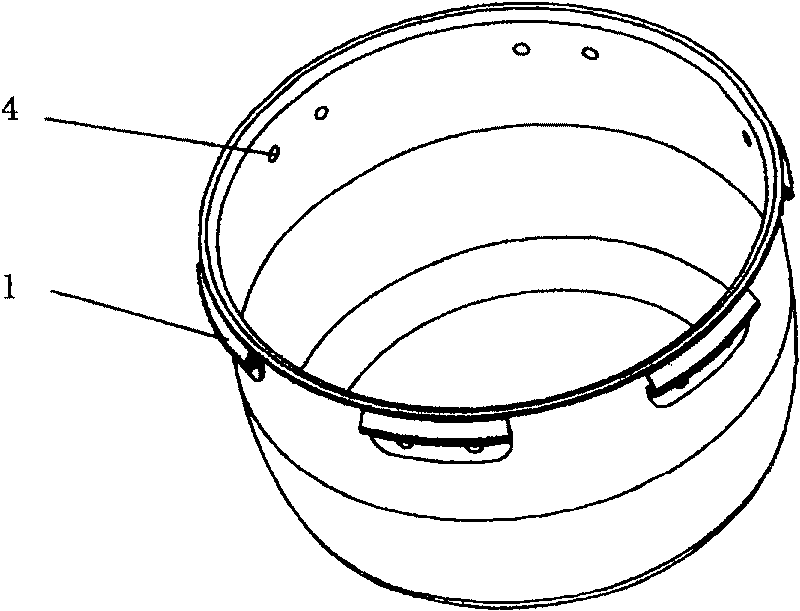

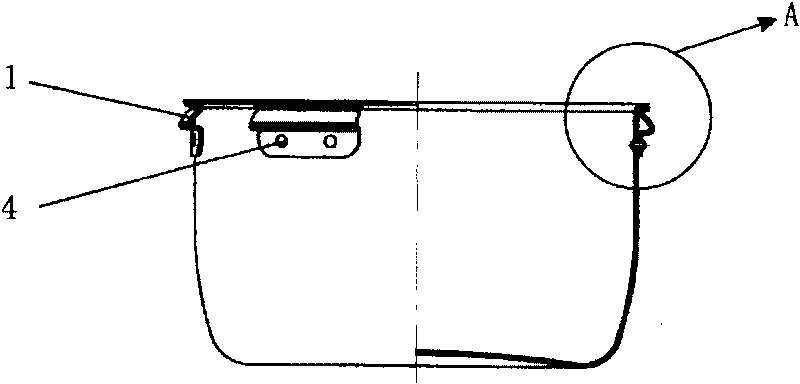

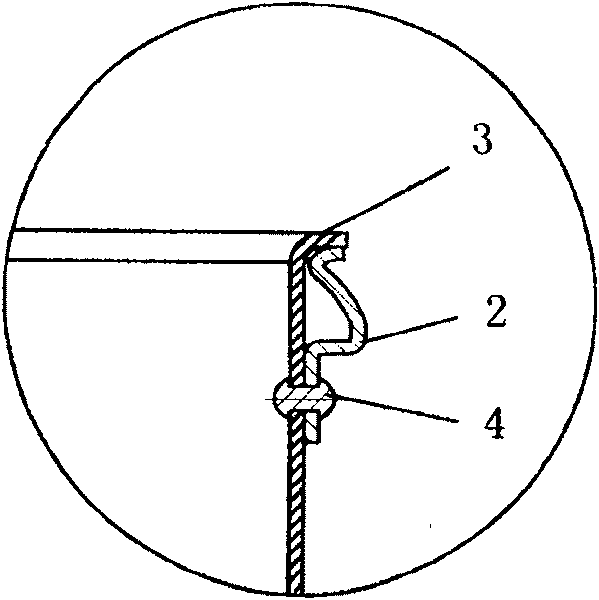

[0023] In the drawings: 1. Support body; 2. Flange portion of support body; 3. Flange portion of pot mouth; 4. Rivet; 5. Circle body.

[0024] Such as Figures 1 to 4 As shown, the inner pot of the pressure cooker includes a pot wall and a pot bottom. The pot wall and the pot bottom form a concave container with an opening. Outwardly protruding support body 1, the cross section of support body 1 is Type, the outer diameter of which is formed is larger than the outer diameter of the pot mouth. The above-mentioned supporting bodies 1 are distributed on the pot wall by several ones, and the top is close to the bottom of the flange portion 3 of the pot mouth. The supporting body 1 is riveted on the outer wall of the pot by the rivet 4 to ensure that the supporting body 1 is fastened on the pot wall. The supporting body 1 guides the force rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com