Solder joint electrode and copper alloy target for forming coating film of solder joint electrode

A technology for joining electrodes and copper alloy targets, which is applied in the direction of welding equipment, circuits, electrical components, etc., can solve the problems of strong force and high price of precious metals, and achieve the effect of reducing the cost of film formation and good solder jointability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

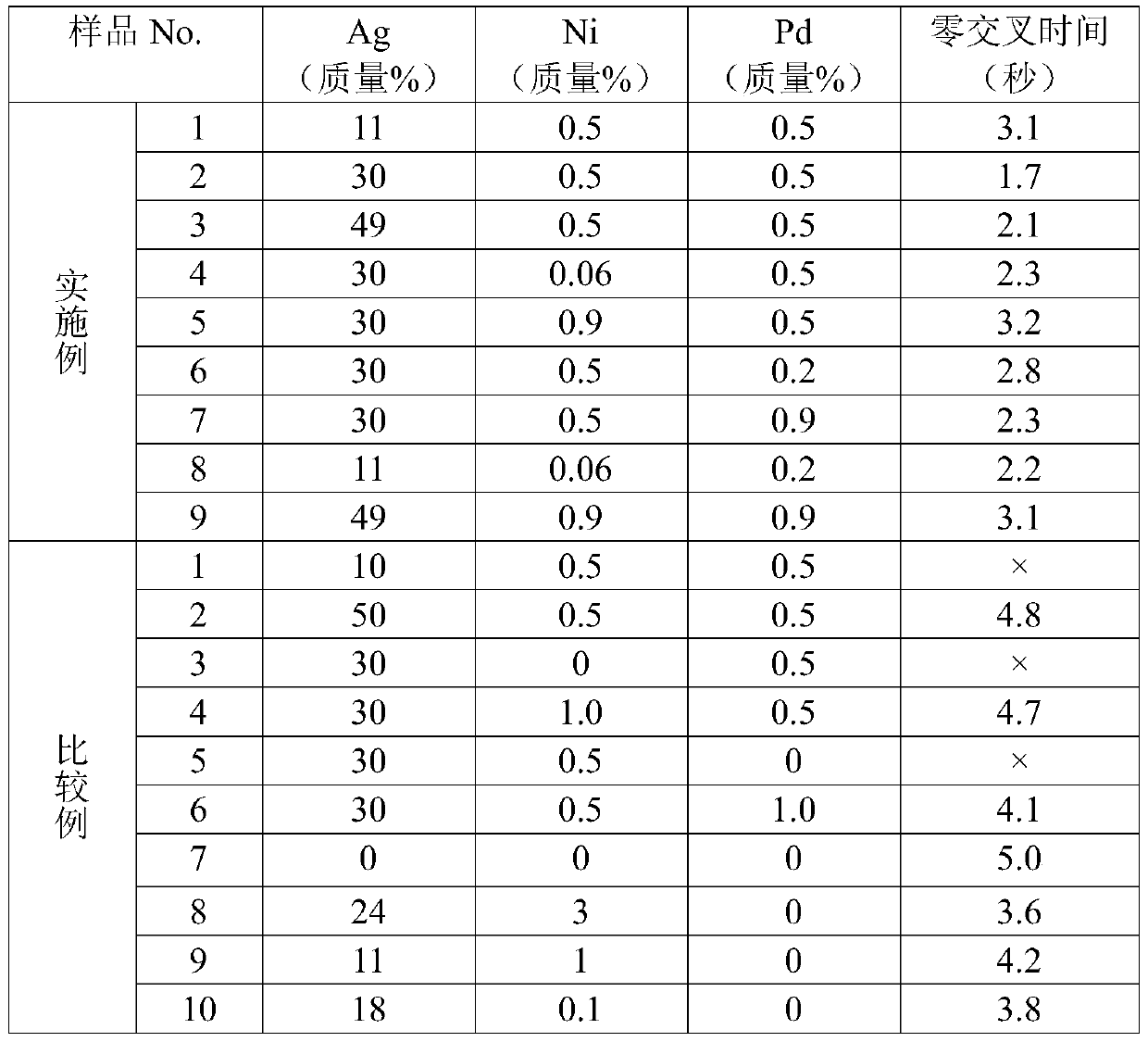

[0048] Hereinafter, although an Example and a comparative example demonstrate this invention in detail, this invention is not limited to the following Example.

[0049] "Examples and Comparative Examples"

[0050]

[0051] In each of the Examples and Comparative Examples, samples of copper alloy targets whose metal materials other than copper contained ratios shown in Table 1 below were produced. Among them, samples 8, 9, and 10 of the comparative example have component compositions similar to samples 9, 1, and 5 of examples of the copper alloy target for film formation of solder joint electrodes described in Patent Document 2.

[0052] More specifically, using a high-frequency melting furnace, vacuumize the chamber to below 0.009Pa, and then introduce argon gas up to 500Pa. In this chamber, the contents are adjusted so that the metal materials other than copper are listed in the following table 1 A metal material composed of copper, silver, nickel and palladium having the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com