Production method for soybean yoghurt with good texture

A soy yogurt and production method technology, applied in milk substitutes, dairy products, applications, etc., can solve the problems of rough taste of soy yogurt, hindrance of soy yogurt, and non-fine texture, so as to achieve the convenience of industrial production and application, and high operational safety , Gel uniform and fine effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

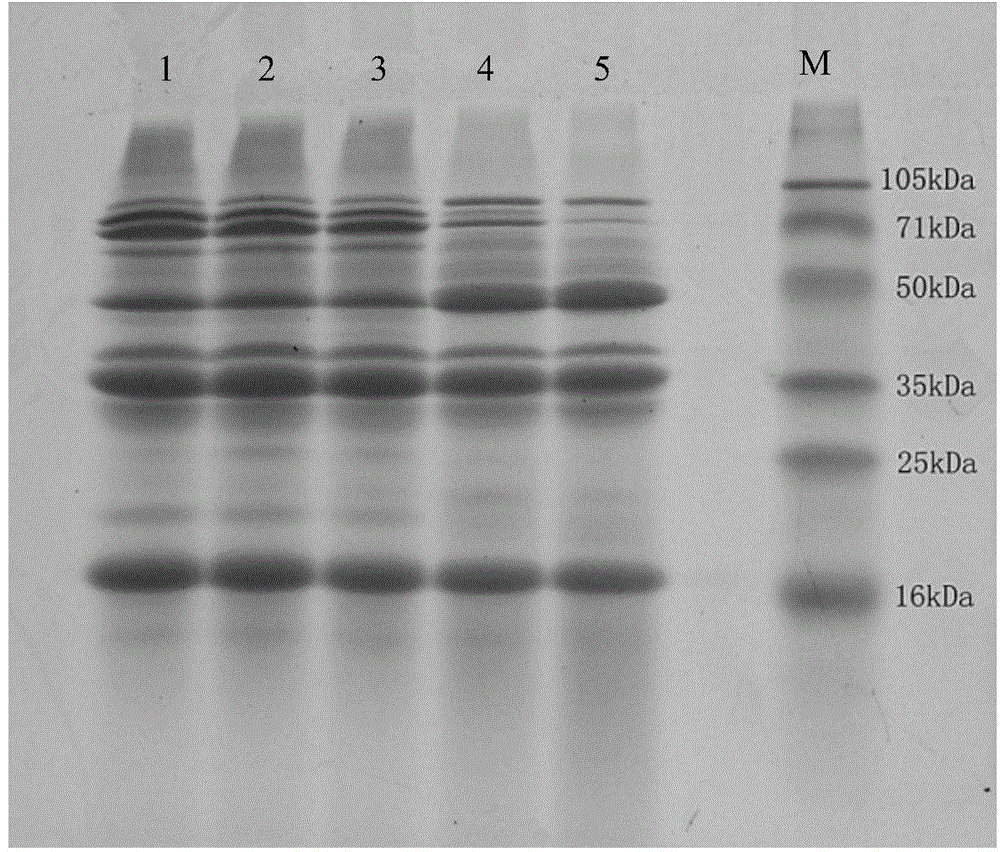

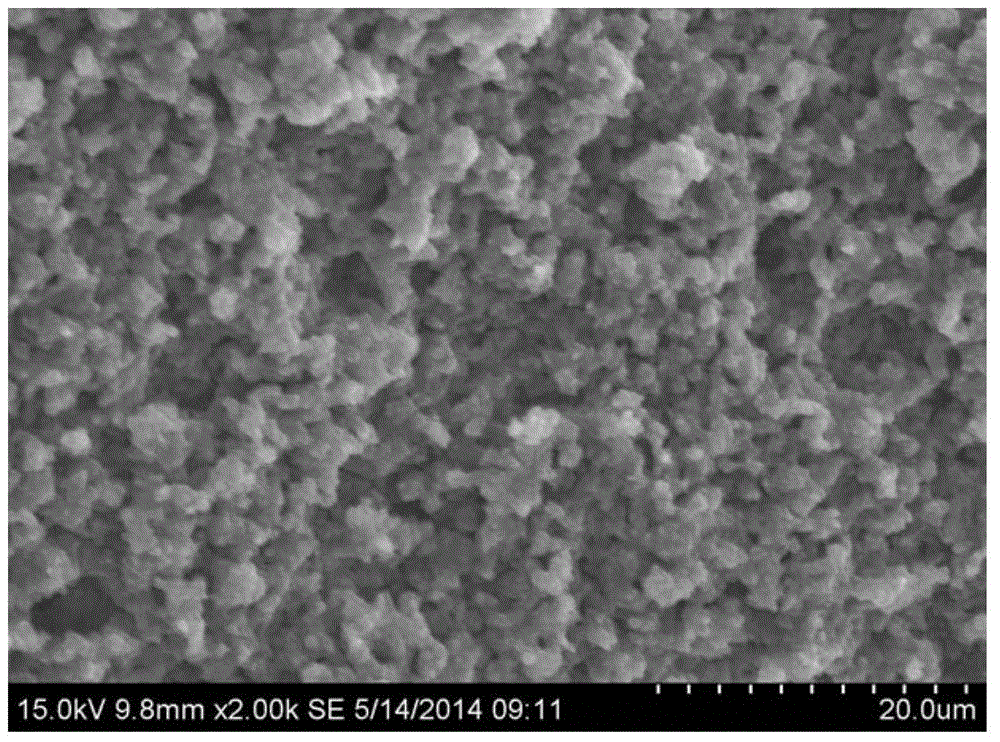

[0041] Embodiment 1 (comparative example, does not add protease treatment)

[0042] In the first step, 200 mL of 12% (w / v, unit: kg / liter) skim milk was prepared, and sterilized by high-pressure steam at 115° C. for 10 minutes. Weigh 0.008g of the direct-injection strain XPL-1 (same as in Example 1) and place it in the sterilized skim milk, shake well, and incubate at 37°C for 12h.

[0043] In the second step, take 100g of soybeans that have been selected and removed, add 400mL of tap water, and add 2g of NaHCO 3 Soak at room temperature for 14 hours. Mix the soaked soybeans with 800mL deionized water, grind them with hot water at 85°C, pass through a 180-mesh sieve to obtain pure soybean milk, then boil it, measure 400mL soybean milk after cooling, add 24g sucrose, 4g lactose, 4g Glucose, fully dissolved, placed in a 500mL Erlenmeyer flask, and cooked at 100°C for 15min.

[0044] In the third step, take 20 mL of the sample activated in the first step and insert it into the...

Embodiment 2

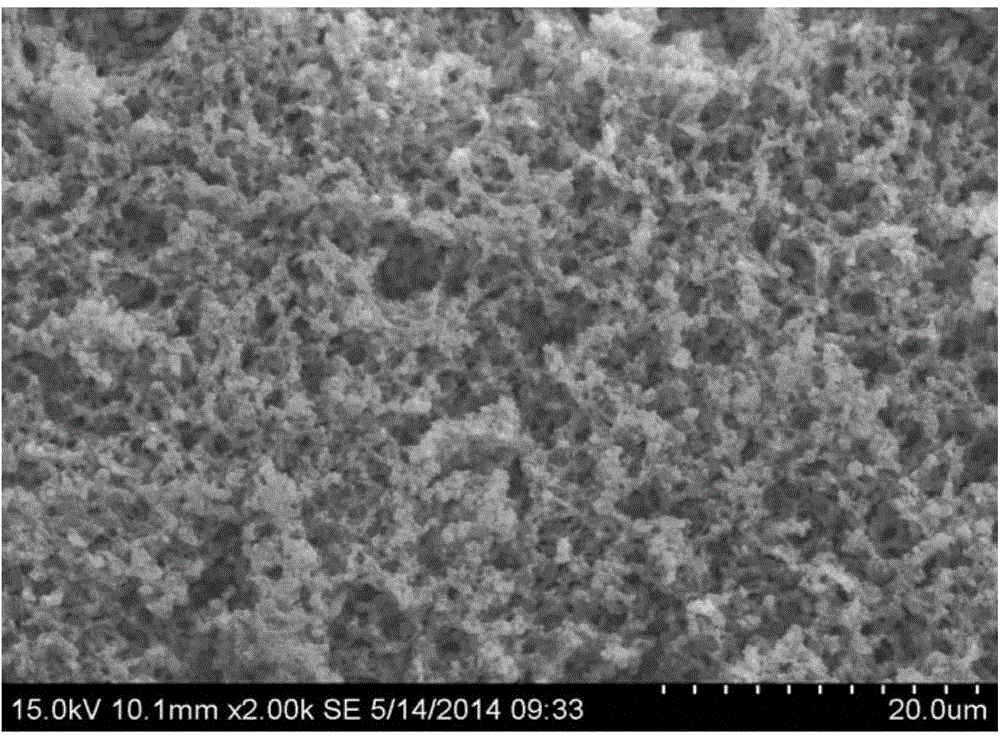

[0046] Embodiment 2 (adding protease pretreatment while soaking beans)

[0047] In the first step, 200 mL of 12% (w / v, unit: kg / liter) skim milk (same as above) was prepared, and sterilized by high-pressure steam at 115° C. for 10 minutes. Take by weighing 0.008g direct-injection bacterial strain XPL-1 ((Danke·Hansen Company direct-injection bacterial strain trade name, containing Lactococcus lactis subsp.cremoris, Lactococcus lactis subsp.lactis, Leuconostoc mesenteorides subsp.cremoris, Lactococcus lactis subsp. .lactis biovar diacetylactis, Streptococcus thermophilus five strains) were placed in sterilized skim milk, shaken well, and incubated at 37°C for 12h.

[0048] In the second step, take 150g of soybeans that have been selected and removed impurities, add 600mL of tap water, add 32μl of Alcalase protease, and add 3g of NaHCO 3 Soak at 25°C for 14h. Mix the soaked soybeans with 1200mL deionized water, grind them with hot water at 85°C, pass through a 180-mesh sieve t...

Embodiment 3

[0052] Embodiment 3 (adding protease pretreatment while soaking beans)

[0053] In the first step, 200 mL of 12% (w / v, unit: kg / liter) skim milk was prepared, and sterilized by high-pressure steam at 115° C. for 10 minutes. Weigh 0.008g of the direct-injection strain XPL-1 (same as in Example 1) and place it in the sterilized skim milk, shake well, and incubate at 37°C for 12h.

[0054] In the second step, take 150g of soybeans that have been selected and removed impurities, add 600mL of tap water, add 64μl of Alcalase protease, and add 3g of NaHCO 3 Soak at 25°C for 14 hours. Mix the soaked soybeans with 1200mL deionized water, grind them with hot water at 85°C, pass through a 180-mesh sieve to obtain pure soybean milk, then boil it, measure 800mL soybean milk after cooling, add 48g sucrose, 8g lactose, 8g Glucose, fully dissolved, placed in a 500mL Erlenmeyer flask, and cooked at 100°C for 15min.

[0055] In the third step, take 40 mL of the sample activated in the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com