Manufacturing method for copper oxide loaded titanium dioxide nano through tube array and application of copper oxide loaded titanium dioxide nano through tube array

A technology of titanium dioxide and copper oxide, which is applied in the direction of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, can solve problems such as failure, lithium battery capacity decline, and electrode material pulverization, and achieve low cost and high charging efficiency. Effects of improved discharge capacity and good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

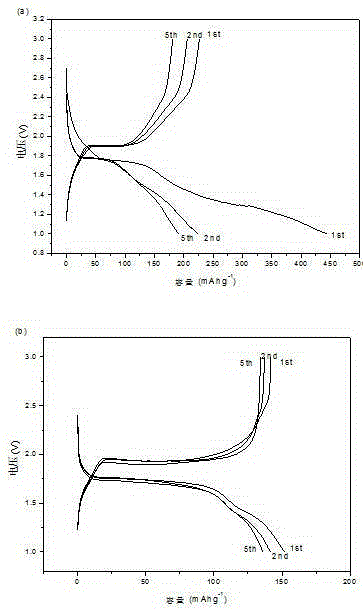

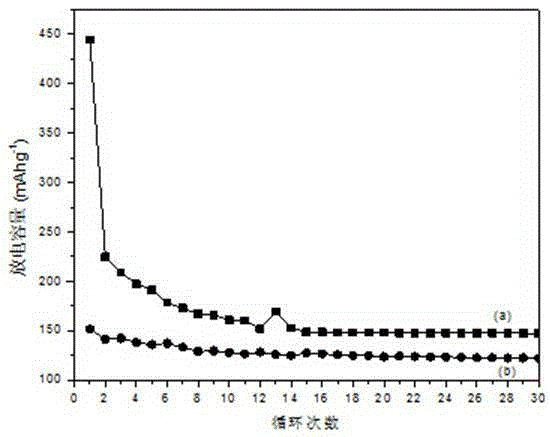

Examples

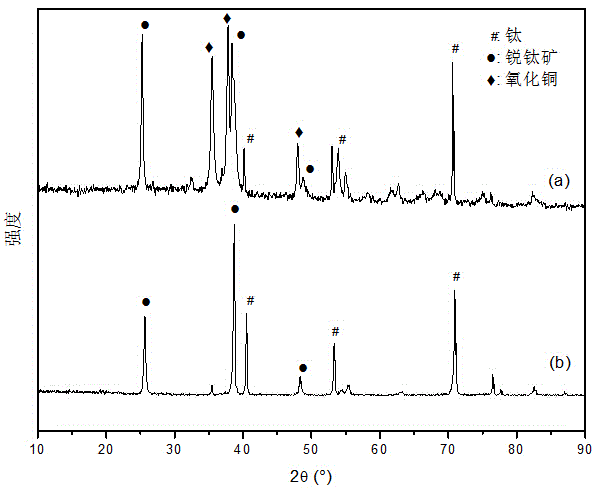

Embodiment 1

[0023] (1) Preparation of titanium dioxide nanotube arrays: immerse pure Ti sheets (thickness 0.1 mm, purity 99.9%) in acetone, absolute ethanol, and deionized water for 10 minutes and ultrasonically clean them to remove surface grease, and dry them in a drying oven for later use; The pure Ti sheet is used as the positive electrode, and the Pt sheet is used as the counter electrode. 4 The ethylene glycol organic solution of F was oxidized at a constant voltage of 60V for 1 hour, and at the end of the anodic oxidation, the voltage was adjusted to 100V and kept for 5s, then the power was turned off, and the bottom barrier layer of the titanium dioxide nanotube array was removed to obtain highly ordered titanium dioxide nanotubes. tube array; the prepared samples were washed with absolute ethanol and dried for later use.

[0024] (2) Preparation of copper oxide-loaded titania nanotube arrays by electrodeposition: the titania nanotube array prepared in step (1) was used as the neg...

Embodiment 2

[0027] (1) Preparation of titanium dioxide nanotube arrays: immerse pure Ti sheets (thickness 0.15 mm, purity 99.8%) in acetone, absolute ethanol, and deionized water for 10 minutes and ultrasonically clean them to remove surface grease, and dry them in a drying oven for later use; The pure Ti sheet is used as the positive electrode, and the Pt sheet is used as the counter electrode. 4 The ethylene glycol organic solution of F was oxidized at a constant voltage of 40V for 2 hours, and at the end of the anodic oxidation, the voltage was adjusted to 80V and kept for 7s, then the power was turned off, and the bottom barrier layer of the titanium dioxide nanotube array was removed to obtain highly ordered titanium dioxide nanotubes. tube array; the prepared samples were washed with absolute ethanol and dried for later use.

[0028](2) Preparation of copper oxide-loaded titania nanotube arrays by electrodeposition: the titania nanotube array prepared in step (1) was used as the neg...

Embodiment 3

[0031] (1) Preparation of titanium dioxide nanotube arrays: immerse pure Ti sheets (thickness 0.2 mm, purity 99.7%) in acetone, absolute ethanol, and deionized water for 10 minutes and ultrasonically clean them to remove surface grease, and dry them in a drying oven for later use; The pure Ti sheet is used as the positive electrode, and the Pt sheet is used as the counter electrode. 4 The ethylene glycol organic solution of F was oxidized at a constant voltage of 20V for 5 hours, and at the end of the anodic oxidation, the voltage was adjusted to 60V and kept for 10s, then the power was turned off, and the bottom barrier layer of the titanium dioxide nanotube array was removed to obtain highly ordered titanium dioxide nanotubes. tube array; the prepared samples were washed with absolute ethanol and dried for later use.

[0032] (2) Preparation of titanium dioxide nanotube arrays loaded with copper oxide by electrodeposition: the titanium dioxide nanotube array prepared in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com