Preparation method of photo-crosslinked sulphonated polysulfone ion exchange membrane

A technology of ion exchange membrane and sulfonated polysulfone, which is applied in the field of preparation of photocross-linked sulfonated polysulfone ion exchange membrane, can solve the problems of decreased dimensional stability, impact on application efficiency, excessive swelling, etc., and achieve high ion conductivity and Selectivity, process low, effect of high ion exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

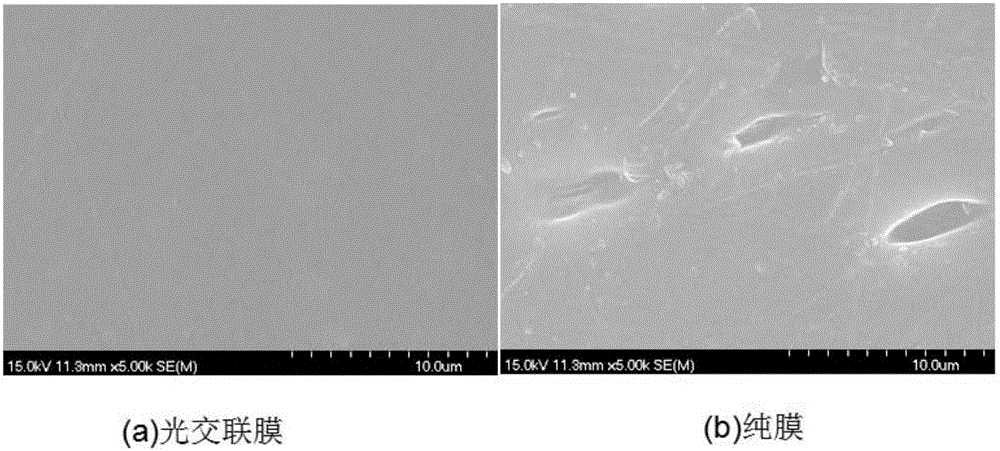

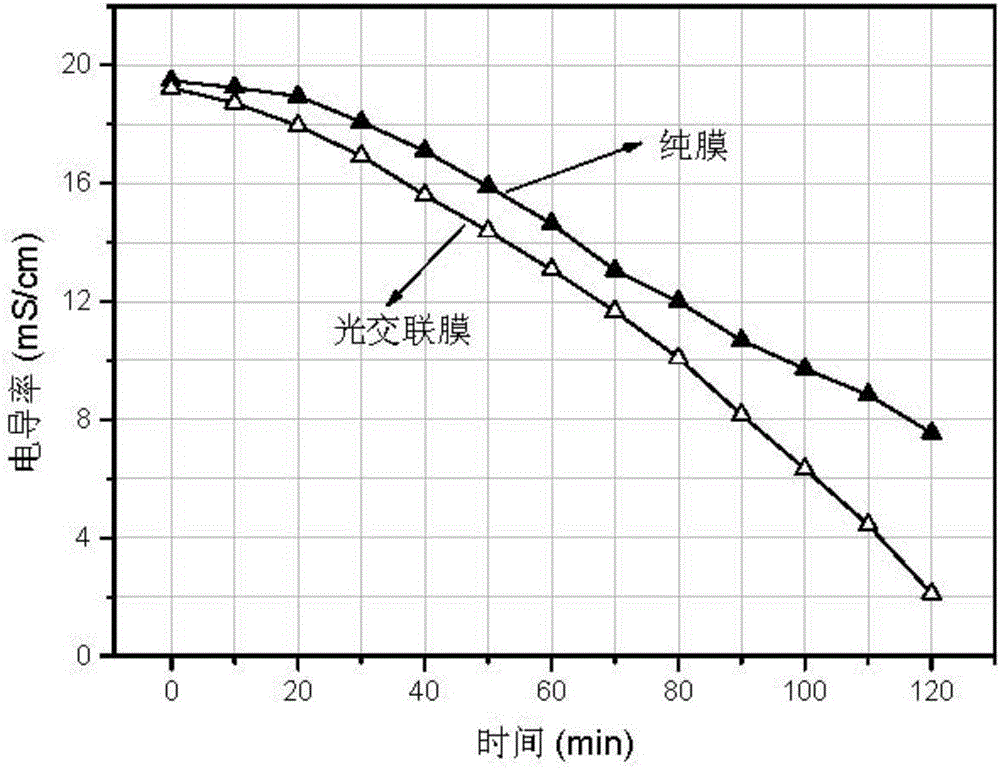

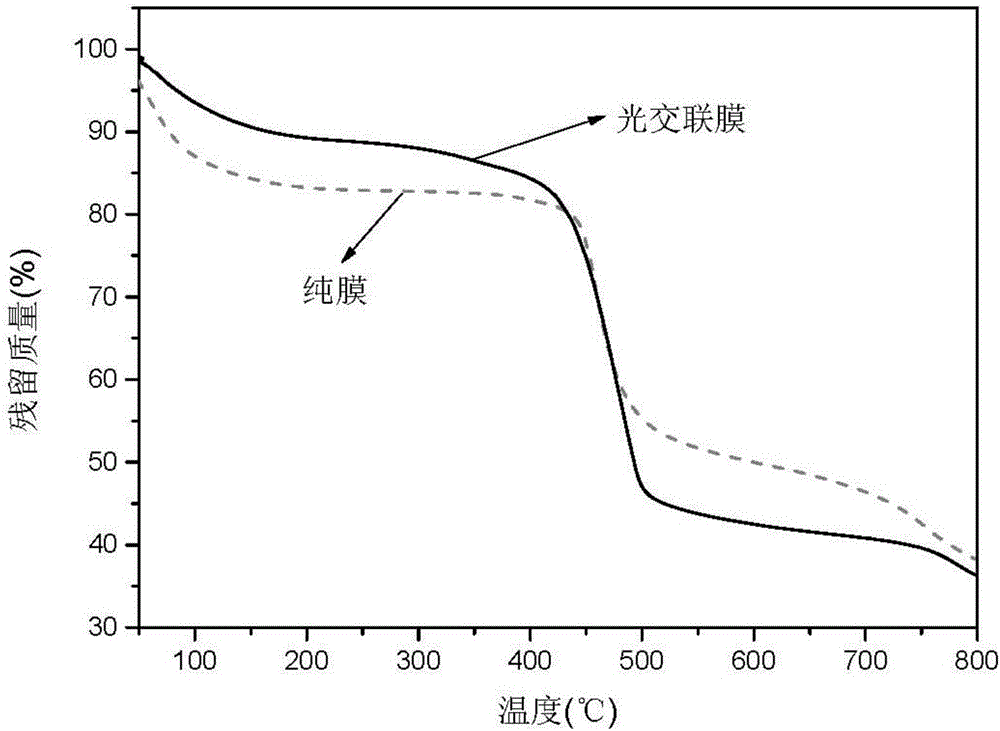

[0027] Accurately weigh 4 g of sulfonated polysulfone with a sulfonation degree of 80%, dissolve it in 16 g of N'N-dimethylformamide (DMF) to form a solution with a mass fraction of 20%, stir at 60°C for 6 hours, and then Set aside to cool. Add 0.3 g of photoinitiator TPO and 1.5 g of crosslinking agent trimethylolpropane triacrylate to the obtained homogeneous solution, stir at room temperature for 3 hours to obtain a homogeneous solution, let it stand overnight for defoaming, and obtain a casting solution. Pour the casting liquid onto a dry, clean and smooth glass plate, and quickly scrape the automatic film scraper perpendicular to the glass plate to form a film with an initial thickness of 600 μm. Put the scraped film into the UV cross-linking apparatus quickly, and after irradiating with ultraviolet light for 15 minutes, quickly place the film at 60°C for 24 hours in vacuum to obtain a photo-crosslinked sulfonated polysulfone film with a sulfonation degree of 80%. .

[...

Embodiment 2

[0030] Accurately weigh 3 g of sulfonated polysulfone with a sulfonation degree of 80%, dissolve it in 17 g of N'N-dimethylformamide (DMF) to form a solution with a mass fraction of 15%, stir at 70°C for 5 hours, and then Set aside to cool. Add 0.3 g of photoinitiator TPO and 1.5 g of crosslinking agent trimethylolpropane triacrylate to the obtained homogeneous solution, stir at room temperature for 3 hours to obtain a homogeneous solution, let it stand overnight for defoaming, and obtain a casting solution. Pour the casting liquid onto a dry, clean and smooth glass plate, and quickly scrape the automatic film scraper perpendicular to the glass plate to form a film with an initial thickness of 600 μm. Put the scraped film into the UV cross-linking apparatus quickly, and after irradiating with ultraviolet light for 15 minutes, quickly place the film at 60°C for 24 hours in vacuum to obtain a photo-crosslinked sulfonated polysulfone film with a sulfonation degree of 80%. .

[...

Embodiment 3

[0033] Accurately weigh 4 g of sulfonated polysulfone with a sulfonation degree of 60%, dissolve it in 16 g of N'N-dimethylformamide (DMF) to form a solution with a mass fraction of 20%, stir at 80°C for 5 hours, and then Set aside to cool. Add 0.2 g of photoinitiator TPO and 1 g of cross-linking agent trimethylolpropane triacrylate to the obtained homogeneous solution, stir at room temperature for 3 hours to obtain a homogeneous solution, let it stand overnight for defoaming, and obtain a casting solution. Pour the casting liquid onto a dry, clean and smooth glass plate, and quickly scrape the automatic film scraper perpendicular to the glass plate to form a film with an initial thickness of 600 μm. Put the scraped membrane into the UV cross-linking apparatus quickly, and after irradiating with ultraviolet light for 10 minutes, quickly place the membrane at 60°C for 24 hours in vacuum to obtain a photo-crosslinked sulfonated polysulfone membrane with a sulfonation degree of 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com