Preparation method and application for nanosheet formed by carbon-coated titanium dioxide nanotube

A titanium dioxide and nanotube technology is applied in the field of preparation of electrode materials for lithium ion batteries, which can solve problems such as unfavorable industrial production, poor repeatability, and complicated experimental procedures, and achieve the effects of good electrochemical performance, low cost, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

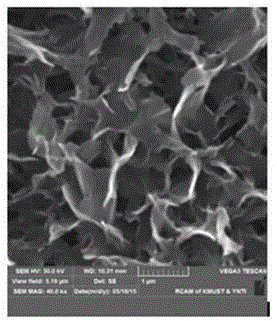

[0030] (1) Cut the pure titanium sheet into 3cm×8cm titanium sheet, ultrasonically vibrate in acetone, absolute ethanol, and distilled water at 25kHz for 15min respectively, remove the grease on the surface of the pure titanium sheet, and obtain a clean pure titanium sheet, press The ratio of 80g / L put the clean pure titanium sheet together with 1.2mol / L sodium hydroxide solution into a 100ml reaction kettle, take it out after reacting at 200°C for 24h, and soak it in 0.5mol / L dilute hydrochloric acid solution for 3h Then take it out, wash with distilled water and alcohol three times respectively, and finally anneal at 500° C. in air for 3 hours to obtain nanosheets composed of titanium dioxide nanotubes.

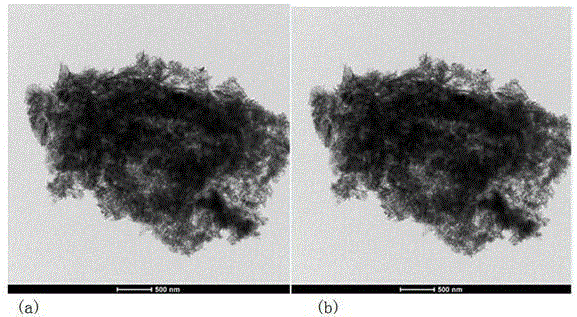

[0031] (2) Put the nanosheets composed of titanium dioxide nanotubes prepared in step (1) and 0.03mol / L glucose solution into a 100ml reactor at a ratio of 5g / L, react at 180°C for 18h, and then In an argon atmosphere, the temperature was raised to 480° C. at 10° C. / min, an...

Embodiment 2

[0036](1) Cut the pure titanium sheet into 3cm×8cm titanium sheet, ultrasonically vibrate in acetone, absolute ethanol, and distilled water at 25kHz for 18min respectively, remove the grease on the surface of the pure titanium sheet, and obtain a clean pure titanium sheet, press The ratio of 100g / L put the clean pure titanium sheet together with 1.6mol / L potassium hydroxide solution into a 100ml reaction kettle, take it out after reacting at 210°C for 18h, and soak it in 0.3mol / L dilute hydrochloric acid solution for 2h Then take it out, wash with distilled water and alcohol three times, and finally anneal at 600° C. in air for 4 hours to obtain nanosheets composed of titanium dioxide nanotubes.

[0037] (2) Put the nanosheets composed of titanium dioxide nanotubes prepared in step (1) and 0.01mol / L glucose solution into a 100ml reactor at a ratio of 1.8g / L, react at 185°C for 24h, and then In an argon atmosphere, the temperature was raised to 490° C. at 13° C. / min, and after ...

Embodiment 3

[0041] (1) Cut the pure titanium sheet into 3cm×8cm titanium sheet, and ultrasonically vibrate in acetone, absolute ethanol, and distilled water at 25kHz for 20min respectively to remove the grease on the surface of the pure titanium sheet to obtain a clean pure titanium sheet, press The ratio of 48g / L put the clean pure titanium sheet together with 1.8mol / L sodium hydroxide solution into a 100ml reaction kettle, take it out after reacting at 220°C for 12h, and soak it in 0.6mol / L dilute hydrochloric acid solution for 4h Then take it out, wash with distilled water and alcohol three times, and finally anneal at 700° C. in air for 2 hours to obtain nanosheets composed of titanium dioxide nanotubes.

[0042] (2) Put the nanosheets composed of titanium dioxide nanotubes prepared in step (1) and 0.05mol / L glucose solution into a 100ml reactor at a ratio of 9g / L, react at 190°C for 20h, and then In an argon atmosphere, the temperature was raised to 500° C. at 15° C. / min, and after c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com