Nanometer modified epoxy powder coating preparation process

A technology of nano-modification and epoxy powder, which is applied in powder coatings, epoxy resin coatings, coatings, etc., and can solve the problem of easy agglomeration, inability to give full play to the excellent properties of nano-materials, and affecting the rheology and smoothness of powder coatings, etc. problems, to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

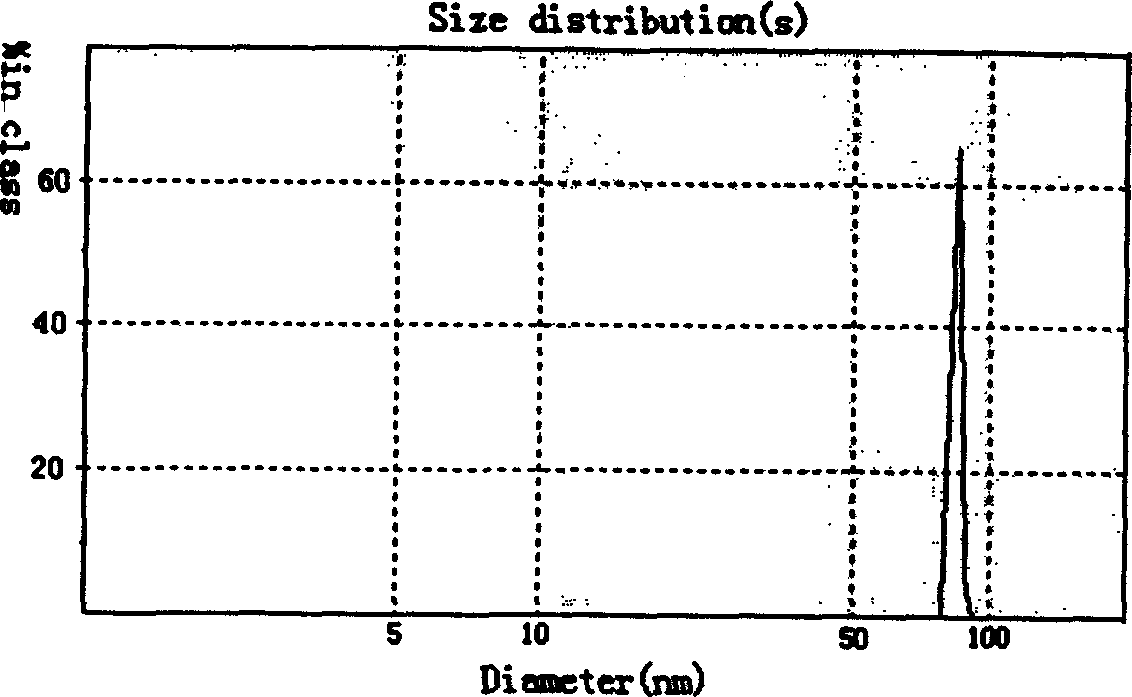

Image

Examples

Embodiment 1

[0017] 1), 2000 gram E-12 epoxy resins are dissolved in 4000 milliliters of acetone, then add the nanometer titanium dioxide that accounts for 2% of epoxy resin massfraction;

[0018] 2), the above-mentioned system was dispersed with ultrasonic waves for 90 minutes under mechanical stirring, and acetone was removed under reduced pressure to obtain nano-modified epoxy resin;

[0019] 3) Weigh the nano-modified epoxy resin, curing agent, leveling agent, filler, pigment and additives according to the designed formula, crush until the particle size is less than 5mm, and then stir and mix in the mixer for 3 minutes;

[0020] 4) Put the uniformly mixed material into the screw extruder to melt and extrude, the temperature of the machine cavity is 100-120°C, the temperature of the extruder head is 120°C-135°C, and the average residence time of the material does not exceed 30 seconds;

[0021] 5) The extruded material is compressed into tablets by a cooling tablet machine, sent to a mi...

Embodiment 2

[0023] 1), 2000 grams of E-12 epoxy resins are dissolved in 4000 milliliters of acetone, then add the nano silicon dioxide that accounts for 5% of epoxy resin massfraction;

[0024] 2), the above-mentioned system was dispersed with ultrasonic waves for 120 minutes under mechanical stirring, and acetone was removed under reduced pressure to obtain nano-modified epoxy resin;

[0025] 3) Weigh the nano-modified epoxy resin, curing agent, leveling agent, filler, pigment and additives according to the designed formula, crush until the particle size is less than 5mm, and then stir and mix in the mixer for 3 minutes;

[0026] 4) Put the uniformly mixed material into the screw extruder to melt and extrude it. The temperature of the machine cavity is 100-120°C, the temperature of the extruder head is 120°C-135°C, and the average residence time of the material is no more than 30 seconds;

[0027] 5) The extruded material is compressed into tablets by a cooling tablet machine, sent to a ...

Embodiment 3

[0029] 1), 2000 gram E-12 epoxy resins are dissolved in 4000 milliliters of acetone, then add the nanometer calcium carbonate that accounts for 10% of epoxy resin massfraction;

[0030] 2), the above-mentioned system was dispersed with ultrasonic waves for 200 minutes under mechanical stirring, and acetone was removed under reduced pressure to obtain nano-modified epoxy resin;

[0031] 3) Weigh the nano-modified epoxy resin, curing agent, leveling agent, filler, pigment and additives according to the designed formula, crush until the particle size is less than 5mm, and then stir and mix in the mixer for 3 minutes;

[0032] 4) Put the uniformly mixed material into the screw extruder to melt and extrude it. The temperature of the machine cavity is 100-120°C, the temperature of the extruder head is 120°C-135°C, and the average residence time of the material is no more than 30 seconds;

[0033] 5) The extruded material is compressed into tablets by a cooling tablet machine, sent t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com