Phosphate cross-linking agent and preparation method thereof, phosphate-based cross-linked gel polymer electrolyte and preparation method and application thereof

A phosphate-based and phosphate-based technology, applied in the field of gel polymer electrolytes, can solve the problems of few varieties of gel polymer electrolytes and lack of research on the influence of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1 (two): (phosphorus-containing crosslinking agent I and two kinds of comonomer crosslinking copolymerization)

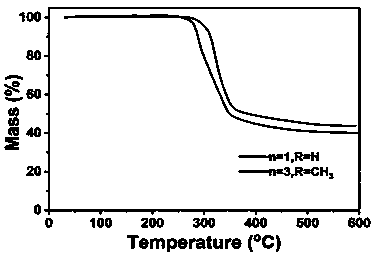

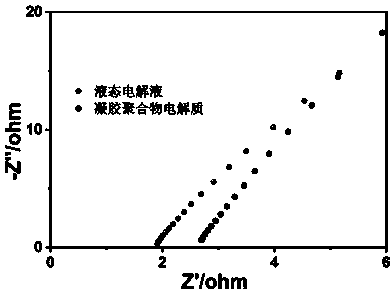

[0071] First, taking a compound (n=1, R=H) in the general formula I as an example, 70 mg of the general formula I, 15 mg of ethyl acrylate, 26 mg of trifluoroethyl methacrylate, 2.3 mg of AIBN, and 1.00 mg of liquid electrolyte for sodium ion batteries g (the electrolyte is sodium perchlorate, the concentration is 1M, the solvent is ethylene carbonate, diethyl carbonate and fluoroethylene carbonate (1:1:0.05, v%), and the precursor solution is obtained after mixing evenly;

[0072] Then according to the conventional assembly method of sodium vanadium phosphate (NVP) sodium ion battery, for example, NVP, Super P, PVDF are ground evenly in NMP solvent by the mass ratio of 80:10:10, and it is coated on the aluminum foil rapidly, then Put it in an oven at 60° C. and dry it overnight, and then cut it with a cutting machine to obtain a positive electrode...

Embodiment 2

[0074] Embodiment 2 (two): (phosphorus-containing crosslinking agent I and two kinds of comonomer crosslinking copolymerization)

[0075] A certain compound (n=3, R=-CH 3 ) as an example, general formula I 79mg, ethyl acrylate 12mg, trifluoroethyl methacrylate 20mg, AIBN 1.8mg, sodium ion battery liquid electrolyte 1.00g (electrolyte is sodium perchlorate, concentration is 1M, solvent is ethylene carbonate ester, diethyl carbonate and fluoroethylene carbonate (1:1:0.05, v%)), and mix uniformly to obtain a precursor solution; the process of assembling a battery from the precursor solution is the same as in Example 1 (two).

Embodiment 3

[0076] Embodiment 3 (two): (phosphorus-containing crosslinking agent II and two kinds of comonomer crosslinking copolymerization)

[0077] Taking a certain compound (n=2, R=-H) in the general formula II as an example, the general formula II is 46 mg, methyl methacrylate 18 mg, trifluoroethyl methacrylate 15 mg, AIBN 1.7 mg, liquid electrolyte for sodium ions 0.72g (the electrolyte is sodium perchlorate, the concentration is 1M, the solvent is ethylene carbonate, diethyl carbonate and fluoroethylene carbonate (1: 1: 0.05, v%)) and mix uniformly to obtain the precursor solution. The process of assembling the battery from the precursor solution is the same as in Example 1 (2). The efficiency of the assembled sodium vanadium phosphate sodium ion battery was 91.9% in the first week, and the discharge capacity retention rate was 70.9% after the battery was cycled for 2800 cycles at a rate of 2C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com