Preparation method of ultrafiltration membrane with enhanced antibacterial property by using modified carbon nanotubes

A technology of carbon nanotube modification and ultrafiltration membrane, which is applied in the direction of chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of enhancing membrane antibacterial property, pollution, microbial contamination, etc., and achieve good antibacterial property, The effect of inhibiting biological contamination and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This example provides a method for preparing a polysulfone membrane containing 0.4% modified carbon nanotubes, the specific steps are as follows:

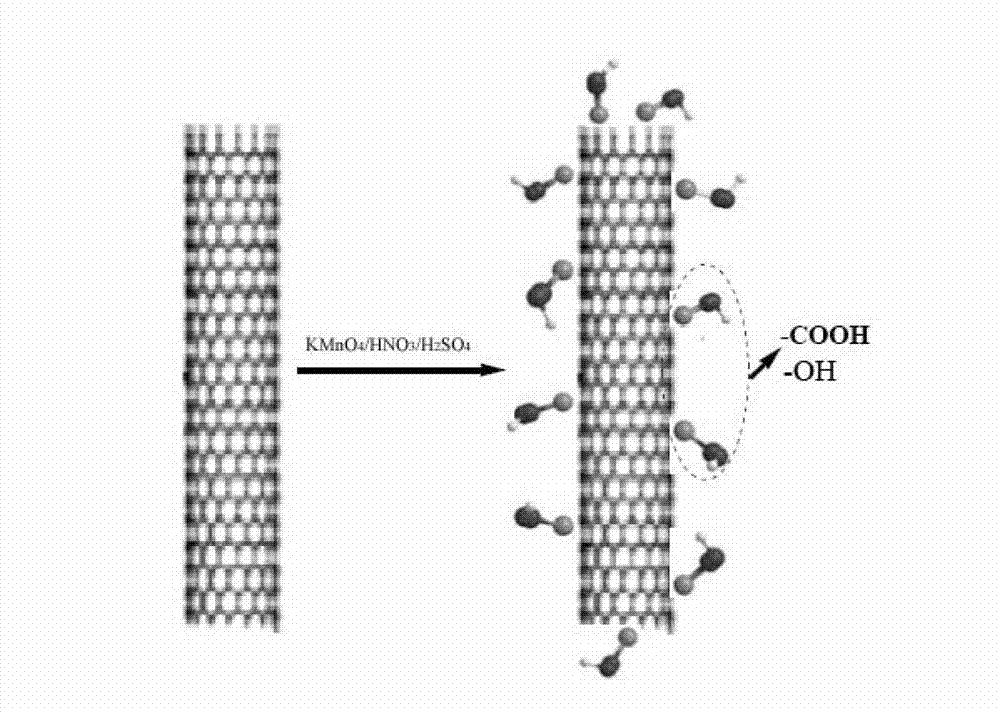

[0043] (1) The original multi-walled carbon nanotubes were placed in an oxidizing solution (potassium permanganate: concentrated sulfuric acid: concentrated nitric acid = 1:3:1) for ultrasonic reaction at 80°C for 6 hours, then diluted with a large amount of deionized water, and then used The microfiltration membrane with a pore size of 0.2 μm was subjected to vacuum filtration to remove carbon residue and some impurities, and the product was washed with deionized water several times until neutral, and finally dried in a vacuum oven at 70°C for 24 hours to obtain the oxidized multi-walled carbon nanotubes;

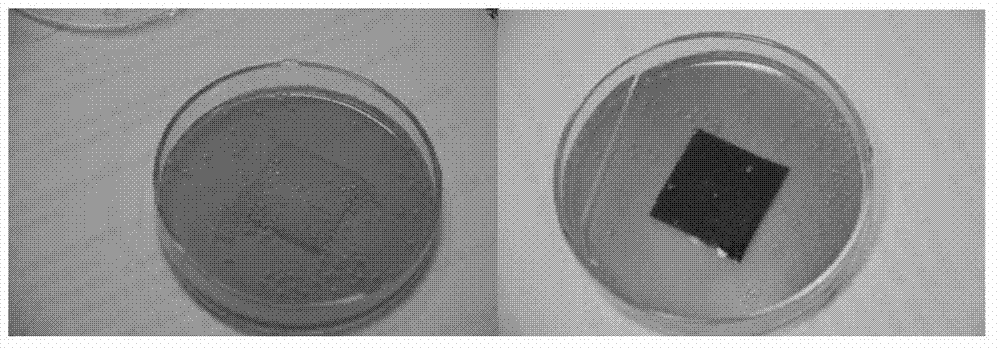

[0044] (2) disperse 0.4g oxidized multi-walled carbon nanotubes in 80.6g N-N dimethylacetamide under ultrasonic conditions, disperse evenly after ultrasonic 2h, add 1g polyvinylpyrrolidone and 18g polysulfone, after sti...

Embodiment 2~3

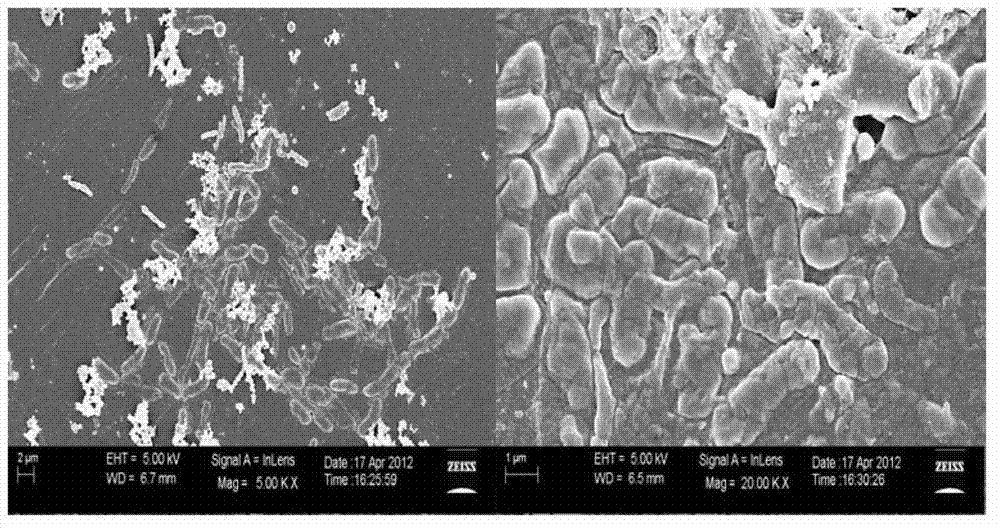

[0055] Only change the content of modified carbon nanotubes to 0.04% and 0.1%, and other operations are the same as in Example 1. The obtained modified carbon nanotube polysulfone membranes have different antibacterial effects, and the antibacterial effects are all good. See Figure 5 .

Embodiment 4

[0057] The oxidation treatment was replaced by isocyanation treatment, and other operations were the same as in Example 1. The antibacterial effect of the obtained modified carbon nanotube polysulfone membrane was more significant, and the 3-hour lethality rate of Escherichia coli could reach 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com