Treating method and treating apparatus of waste water containing organic material

A treatment method and treatment device technology, applied in water/sewage treatment, water treatment parameter control, neutralization water/sewage treatment, etc., to achieve the effect of preventing reactivity reduction and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

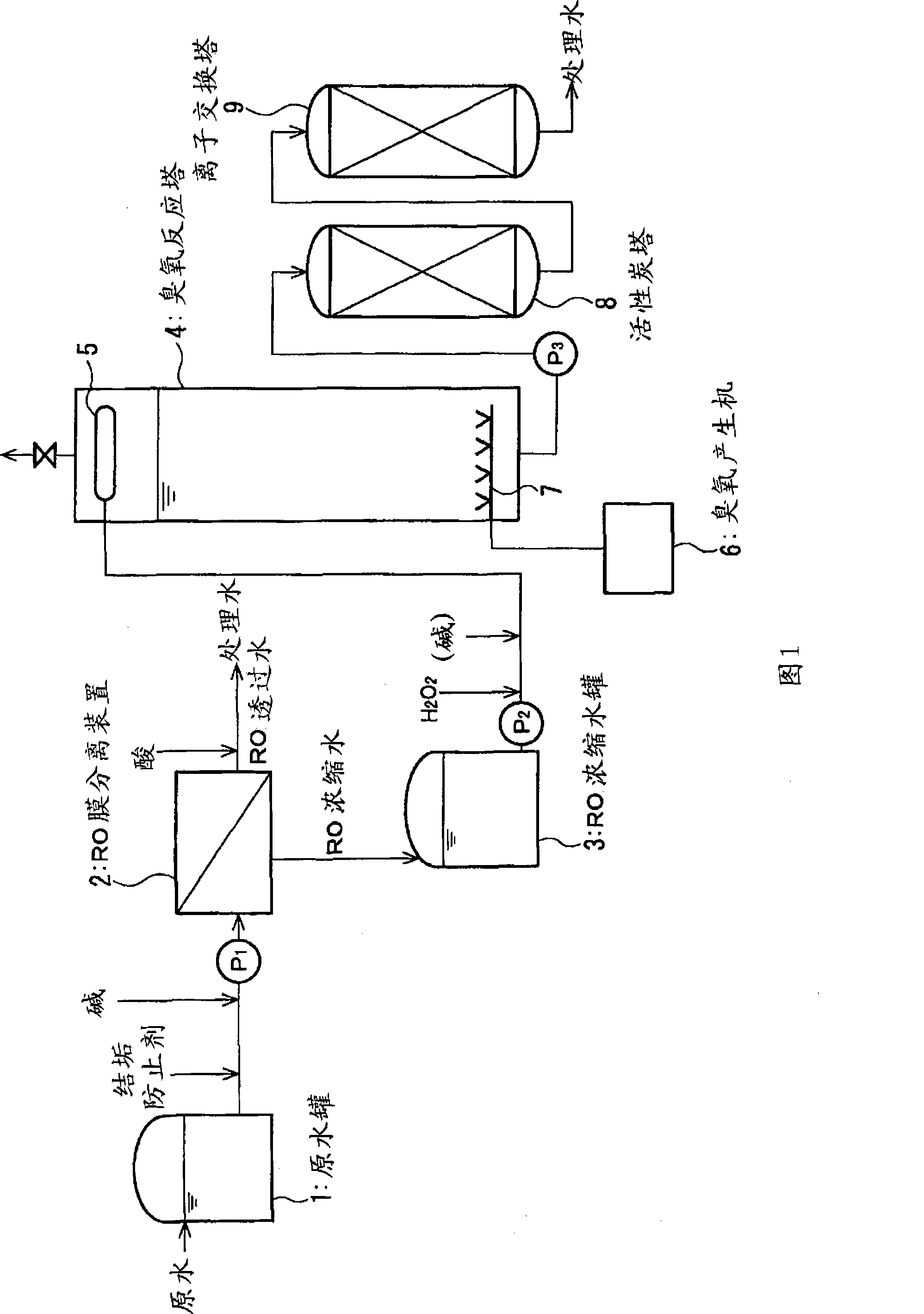

[0097] Use the waste water with a TOC concentration of 5 mg / L and a calcium ion concentration of 10 mg / L as raw water with surfactants as the main body. figure 1 The device shown performs processing. First, add an EDTA-based anti-scaling agent (ethylenediaminetetraacetic acid sodium salt) to the raw water in an amount that is 5 times the calcium ion concentration of the raw water. Then, add NaOH to make the pH 10.5, and use the RO membrane separation device (day The low-pressure aromatic polyamide RO membrane "ES-10" manufactured by Toden Kogyo Co., Ltd. is subjected to RO membrane separation treatment under the conditions of a water flow rate of 80 L / h and a recovery rate of 75%.

[0098] After adding 1.2 times the amount of hydrogen peroxide to TOC to the RO concentrated water obtained by the RO membrane separation treatment, ozone was added to the amount of 10 times the TOC. Then, water was passed to the activated carbon tower under the condition of SV 10 / h, and then the effl...

Embodiment 2

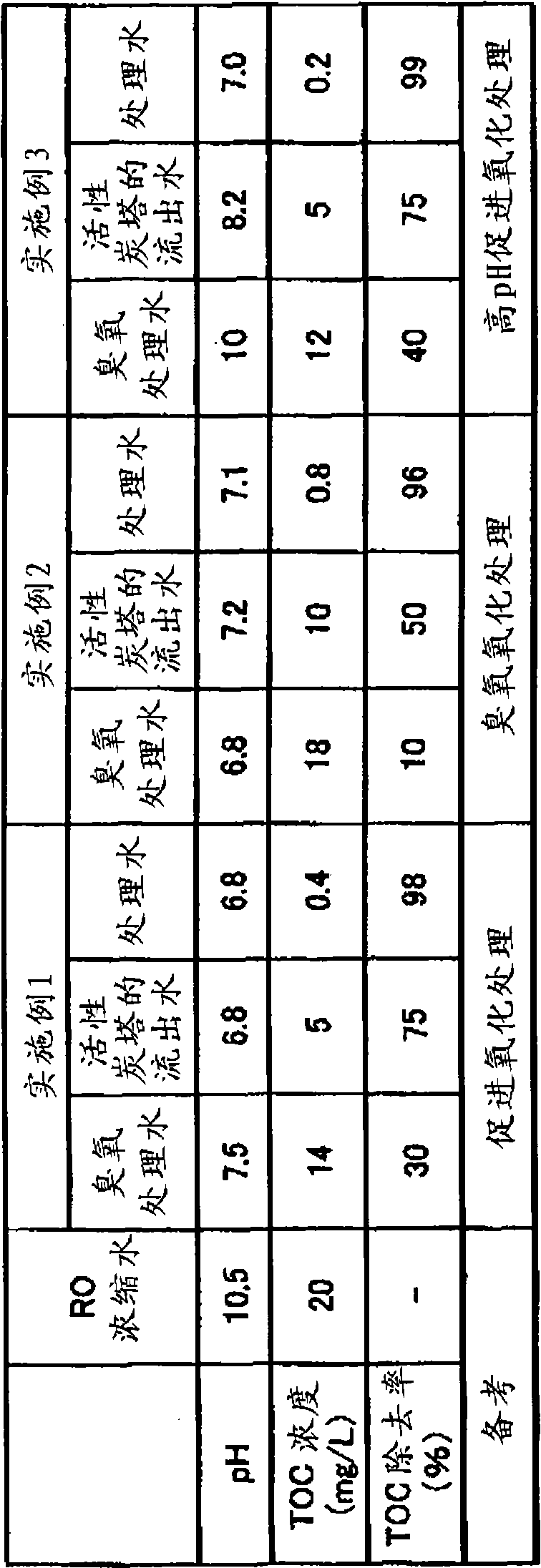

[0101] Except that hydrogen peroxide was not added to the RO concentrated water, the treatment was carried out in the same manner as in Example 1, and the pH, TOC concentration and TOC removal rate of the ozone-treated water (the effluent water of the ozone reaction tower) and the effluent water of the activated carbon tower were studied. The results of pH, TOC concentration, and TOC removal rate, as well as the pH, TOC concentration, and TOC removal rate of the treated water (the effluent water of the ion exchange tower) are shown in Table 1.

Embodiment 3

[0103] Except that the amount of alkali added was increased so that the pH of the ozone-treated water reached 10, the treatment was carried out in the same manner as in Example 1, and the pH, TOC concentration, and TOC removal rate of the ozone-treated water (the effluent water of the ozone reaction tower) were studied, and Table 1 shows the pH, TOC concentration, and TOC removal rate of the effluent water of the activated carbon tower, and the pH, TOC concentration, and TOC removal rate of the treated water (the effluent water of the ion exchange tower).

[0104] Table 1

[0105]

[0106] It can be seen from Table 1 that according to the present invention, TOC in RO concentrated water can be highly removed. Possibility of industrial application

[0107] The present invention can be effectively used in water treatment for the discharge or recovery and reuse of waste water containing high to low concentration TOC discharged from the field of electronic equipment manufacturing, semico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com