Method and composition for treatment of nets for aquaculture

A technology of uses, biocides, applied in the direction of chemicals for biological control, botanical equipment and methods, applications, etc., can solve the problems of expensive, time-consuming, long drying time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: Preparation according to the antifouling preparation of the present invention

[0065] Table 1: Micronized Cu 2 Preparation of O dispersion

[0066]

[0067] The Cu 2 O dispersions are used to prepare antifouling formulations.

[0068] Table 2: Preparation of antifouling formulations*

[0069]

[0070] *Specific gravity = 1.289, % solids weight = 36.83, % solids volume = 28.

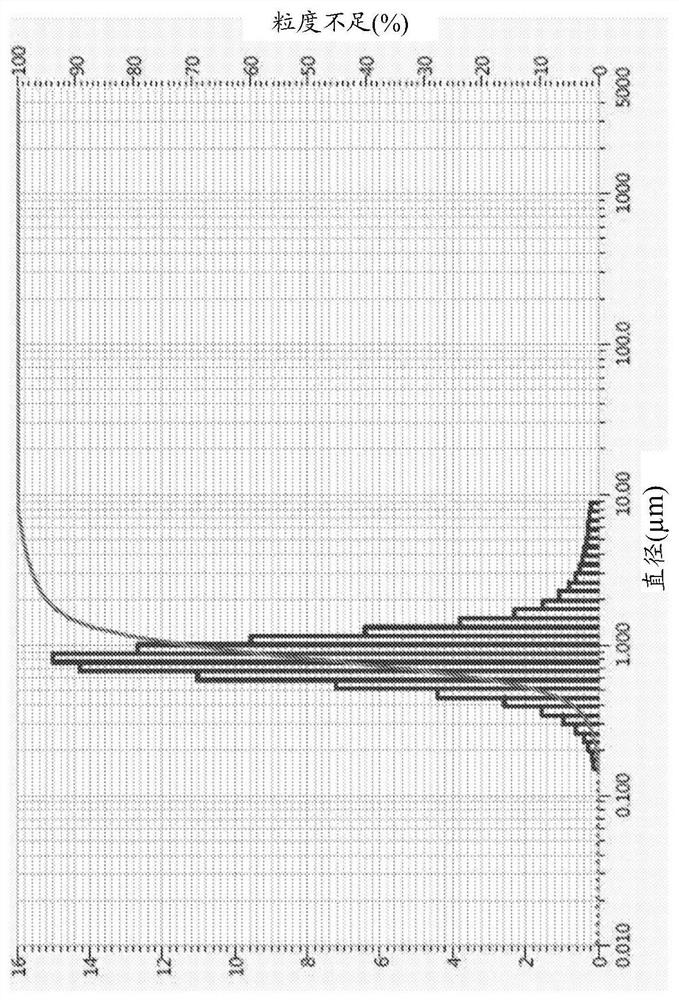

[0071] The particle size distribution curves of the antifouling formulations of Table 2 have been determined by laser light scattering analysis. The resulting particle size distribution curve (particle size as a function of % particle accumulation relative to the total sample) is depicted in FIG. 1 .

[0072] The median and average particle sizes calculated from this curve were about 0.81196 μm and about 0.98811 μm, respectively. Particle size values for selected cumulative % of particles are described in Table 3. The d-values, in particular d10, d50 and d90, have be...

Embodiment 2

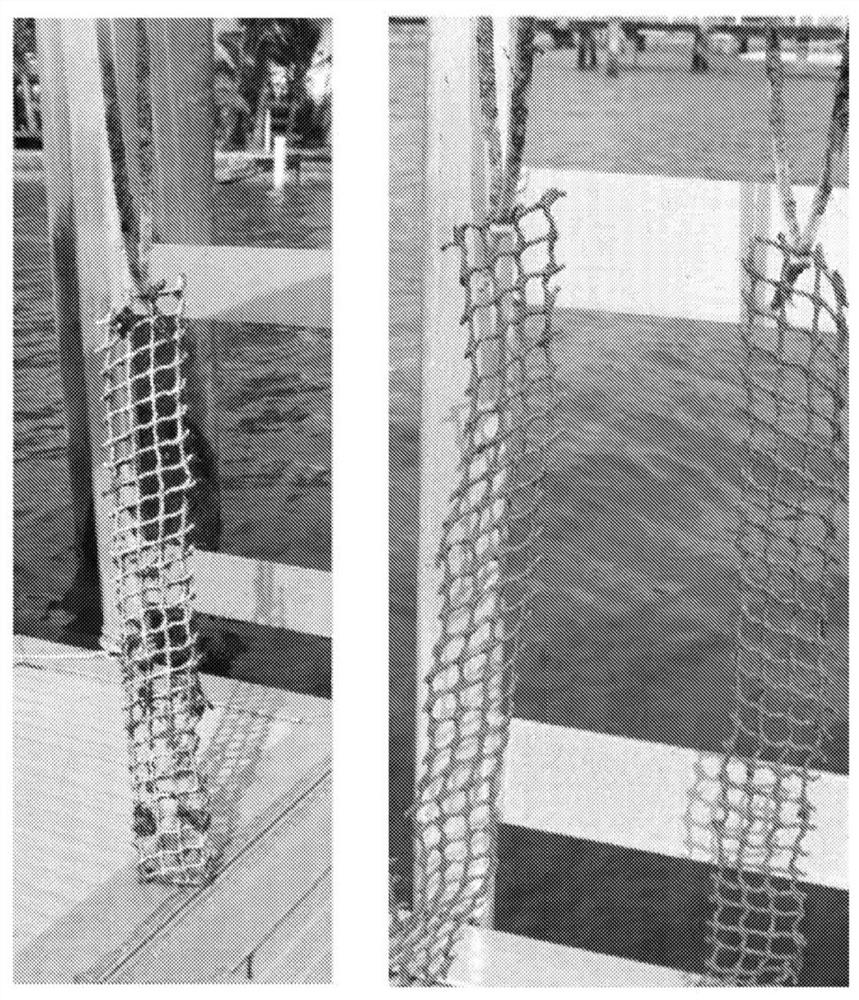

[0076] Embodiment 2: Comparison of fishing nets

[0077] The feasibility of applying the antifouling formulation via the method of the invention to fishing nets ("experimental nets") was compared with nets impregnated with the antifouling formulation of Example 1 alone ("control nets"). The fishnet used for this comparative test was a commonly used nylon fishnet.

[0078] For the test mesh, approximately 30cm x 30cm nylon mesh was cut into small pieces and rolled into a bundle. The bundle was placed in an aluminum pan filled with the antifouling formulation according to Table 2. The disc was then placed into a laboratory scale pressure vessel with fittings to allow both vacuum and pressure to be applied. A vacuum of about 0 kPa was applied for a period of 30 minutes. After 30 minutes, the vacuum was released and the antifouling formulation was removed by decanting. The web was then again subjected to a vacuum of about 0 kPa for 30 minutes to remove any antifouling formul...

Embodiment 3

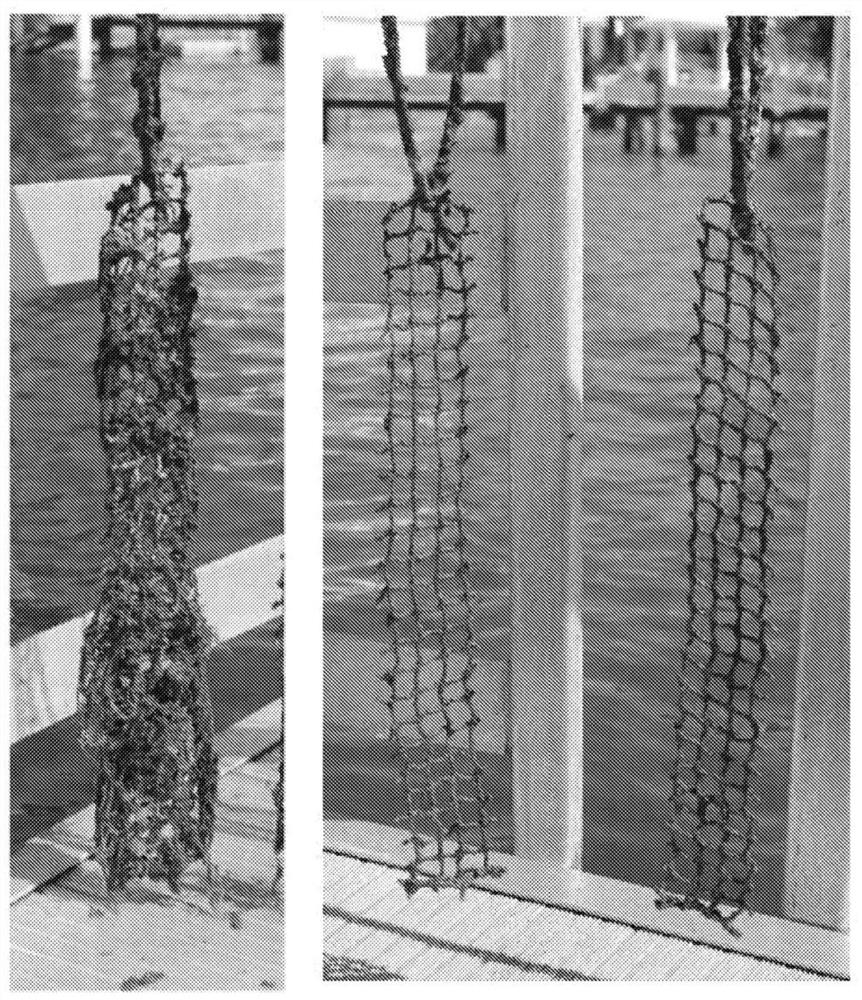

[0088] Example 3: Penetration Depth of Antifouling Marine Coatings in Fishing Nets

[0089] The penetration depth of marine antifouling formulations into fishing nets was compared for two different application methods and two different antifouling formulations. The two antifouling formulations used were the antifouling formulation of the invention ("experimental antifouling formulation"), ie according to Table 2, and the "competitor's" antifouling formulation ("competition"). "Competitor's antifouling formulation" means a typical commercially available antifouling formulation; it is highly similar to the antifouling formulation of the present invention ("experimental antifouling formulation"); The main difference in antifouling formulations is that the active agent is not in micronized form. The two methods compared are the vacuum process according to the invention (vacuum, experiment) and the conventional impregnation method (impregnation, comparison).

[0090] Table 5: P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com