Polydopamine synergistic nanoparticle modified PVDF (Polyvinylidene Fluoride) membrane and preparation method thereof

A nanoparticle modification, polydopamine technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor PVDF membrane structure, non-hydrophilic membrane surface, easy to be polluted, etc. The effect of hydrophilicity, improving membrane pore structure, and improving pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention discloses a method for preparing a PVDF membrane modified by polydopamine synergistically with nanoparticles, comprising the following steps:

[0037] Preparation of inorganic nanoparticles;

[0038] Preparation of the buffer solution: prepare the Tris solution and the dilute acid solution respectively, and mix the Tris solution and the dilute acid solution evenly to obtain the buffer solution;

[0039] Preparation of modified solution: adding inorganic nanoparticles and dopamine into the buffer solution, stirring evenly to obtain modified solution;

[0040] Preparation of modifier: Grinding the solid obtained after drying the modified solution to obtain polydopamine powder doped with nanoparticles;

[0041] Preparation of casting solution: dissolving polyvinylidene fluoride and porogen in an organic solvent, stirring evenly, then adding a certain amount of polydopamine powder doped with nanoparticles, heating and stirring evenly...

Embodiment 1

[0052] A method for preparing polydopamine synergistically modified PVDF membrane with nano zinc oxide, the specific steps are as follows:

[0053] 1) Weigh 20g of zinc chloride, dissolve it in 250mL of deionized water, weigh 10g of ammonium bicarbonate and dissolve it in it, add dilute hydrochloric acid dropwise to adjust the pH to about 9, filter the white precipitate obtained by the reaction, and use 0.2% carbonic acid Washing and drying with sodium hydrogen solution, calcining and grinding in a muffle furnace to obtain ultra-pure nano-zinc oxide, the temperature of the muffle furnace calcining is 600°C, and the heating rate is 1°C·min -1 , The calcination time is 4h.

[0054] 2) Prepare 0.01mol / L Tris solution;

[0055] 3) prepare 0.01mol / L hydrochloric acid solution;

[0056] 4) Mix the tris solution obtained in step 2 and the hydrochloric acid solution obtained in step 3 to obtain a buffer solution, and adjust the pH to 7.5 with a pH meter;

[0057] 5) Add dopamine an...

Embodiment 2

[0065] Step 1~step 6 and step 8 are the same as embodiment 1;

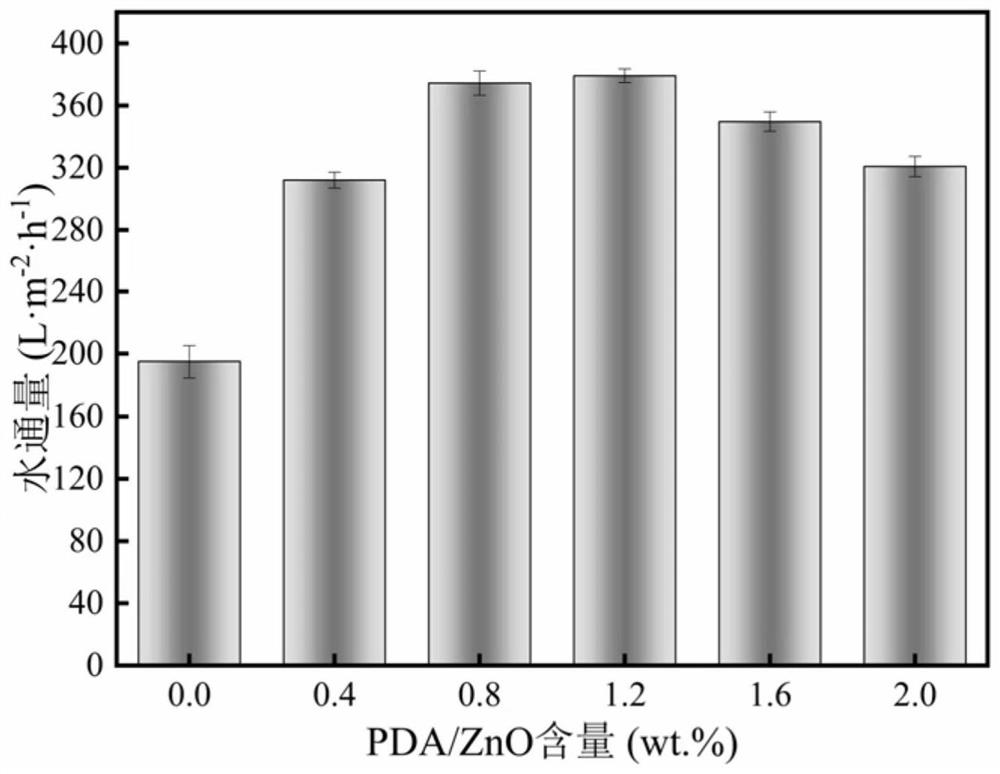

[0066] Step 7) Prepare a solution of polyvinylidene fluoride, polyvinylpyrrolidone, and N,N dimethylacetamide at a mass ratio of 15:1:84, stir for 4 hours under the condition of 200r / min, and then add the mass fraction to account for 1 % polydopamine doped with nano-ZnO to obtain casting solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com