A polyamide composite reverse osmosis membrane with anti-biological fouling properties and preparation method thereof

A technology of anti-biological fouling and reverse osmosis membrane, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of polyamide composite reverse osmosis membrane biofouling, etc., to ensure long-term effectiveness and overcome limitations The effect of simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing a polyamide composite reverse osmosis membrane with anti-biological fouling properties, comprising the following steps: (1) preparation of a polyamide composite reverse osmosis membrane: covering the porous ultrafiltration membrane support layer by interfacial polymerization Aromatic polyamide separation layer to obtain polyamide composite reverse osmosis membrane; (2) preparation of modification solution: dissolve the anti-adhesion unit or its precursor, the water-soluble inorganic salt corresponding to the antibacterial unit, the structure adjustment unit and the auxiliary agent in A buffer solution to obtain a modified solution; that is, the modified solution is a buffer solution comprising an anti-adhesion unit or its precursor, a water-soluble inorganic salt corresponding to a bacteriostatic unit, a structural adjustment unit and an auxiliary agent; (3) anti-biological pollution function Modification of ingr...

Embodiment 1

[0079] The preparation method of the polyamide composite reverse osmosis membrane with anti-biological fouling properties in the present embodiment is as follows: the polyamide composite reverse osmosis membrane prepared in Comparative Example 1 is used as the membrane to be modified, and the surface of the membrane is mixed with dopamine hydrochloride 2g / L , copper sulfate 5mM, taurine 2g / L, hydrogen peroxide 20mM tris-hydrochloric acid weak alkaline buffer solution (pH 8.5, concentration 50mM) at 25°C for 60min; then rinse with a large amount of pure water On the surface of the membrane, a polyamide composite reverse osmosis membrane with anti-biological fouling properties is obtained.

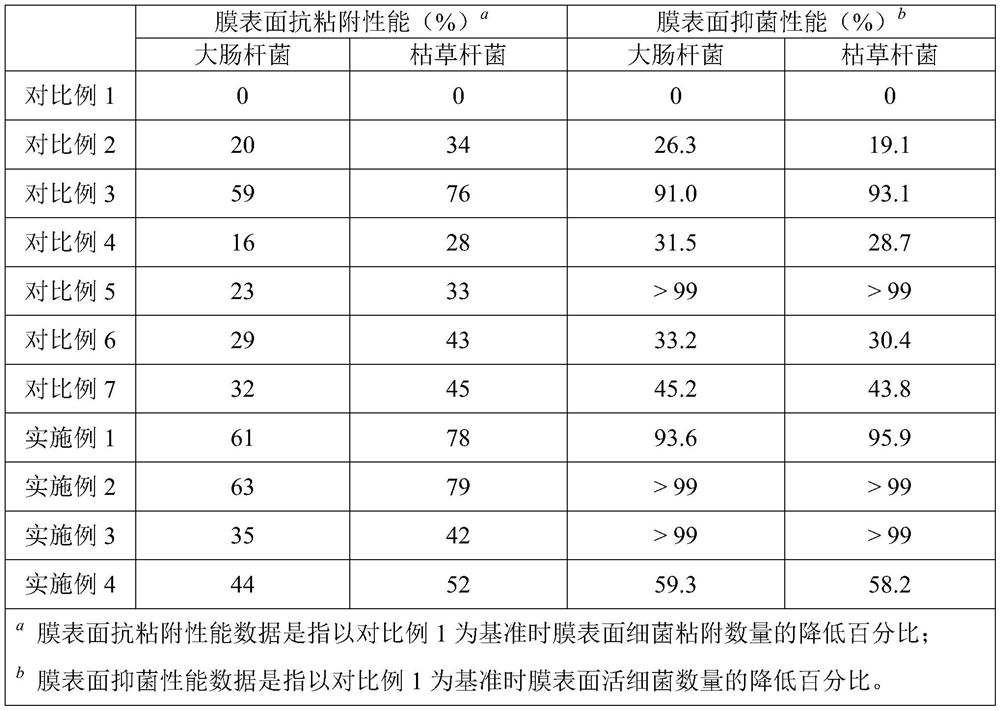

[0080] The polyamide composite reverse osmosis membrane obtained in Example 1 was tested for anti-adhesion performance and antibacterial performance, and the test method was the same as that of Comparative Example 1. The measured performance data are shown in Table 1.

Embodiment 2

[0082] The preparation method of the polyamide composite reverse osmosis membrane with anti-biological fouling properties in the present embodiment is as follows: the polyamide composite reverse osmosis membrane prepared in Comparative Example 1 is used as the membrane to be modified, and the surface of the membrane is mixed with dopamine hydrochloride 2g / L , copper sulfate 5mM, β-alanine 2g / L, hydrogen peroxide 20mM tris-hydrochloric acid weak alkaline buffer solution (pH 8.5, concentration 50mM) contacted at 25 ℃ for 60min; Wash the surface of the membrane with water to obtain a polyamide composite reverse osmosis membrane with anti-biological fouling properties.

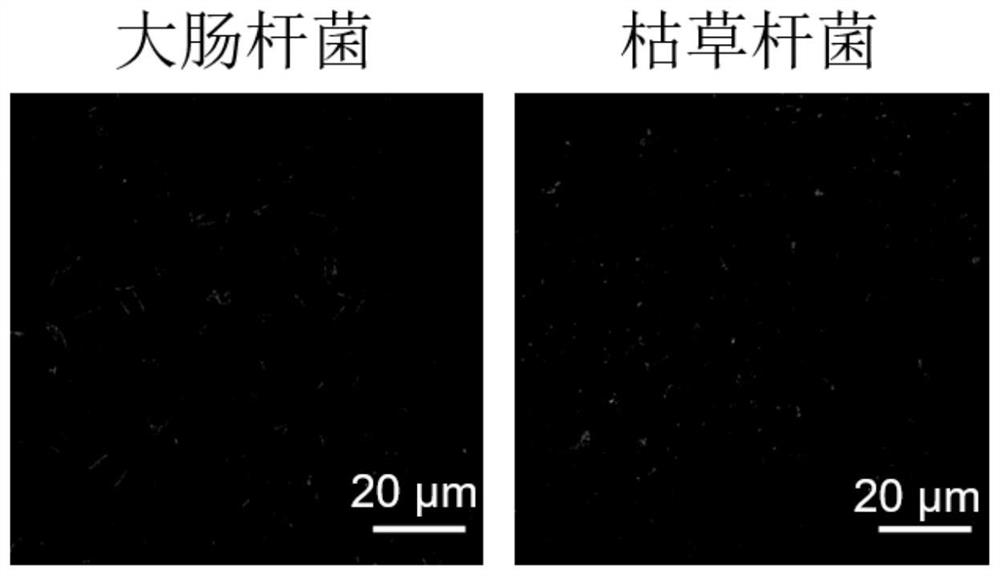

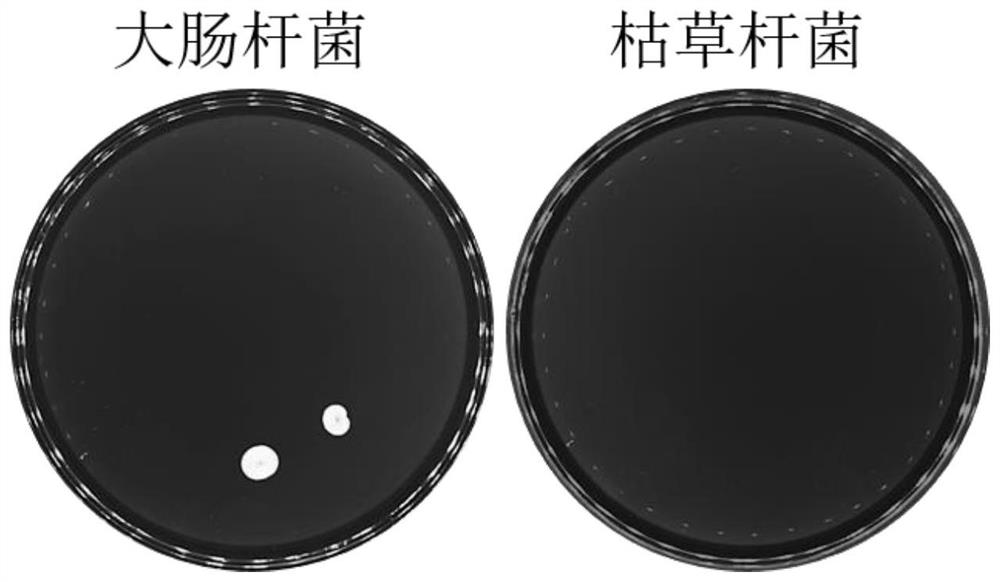

[0083] The polyamide composite reverse osmosis membrane obtained in Example 2 was tested for anti-adhesion performance and antibacterial performance, and the test method was the same as that of Comparative Example 1. figure 1 It is a laser confocal scanning microscope picture, and it can be seen that the number of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com