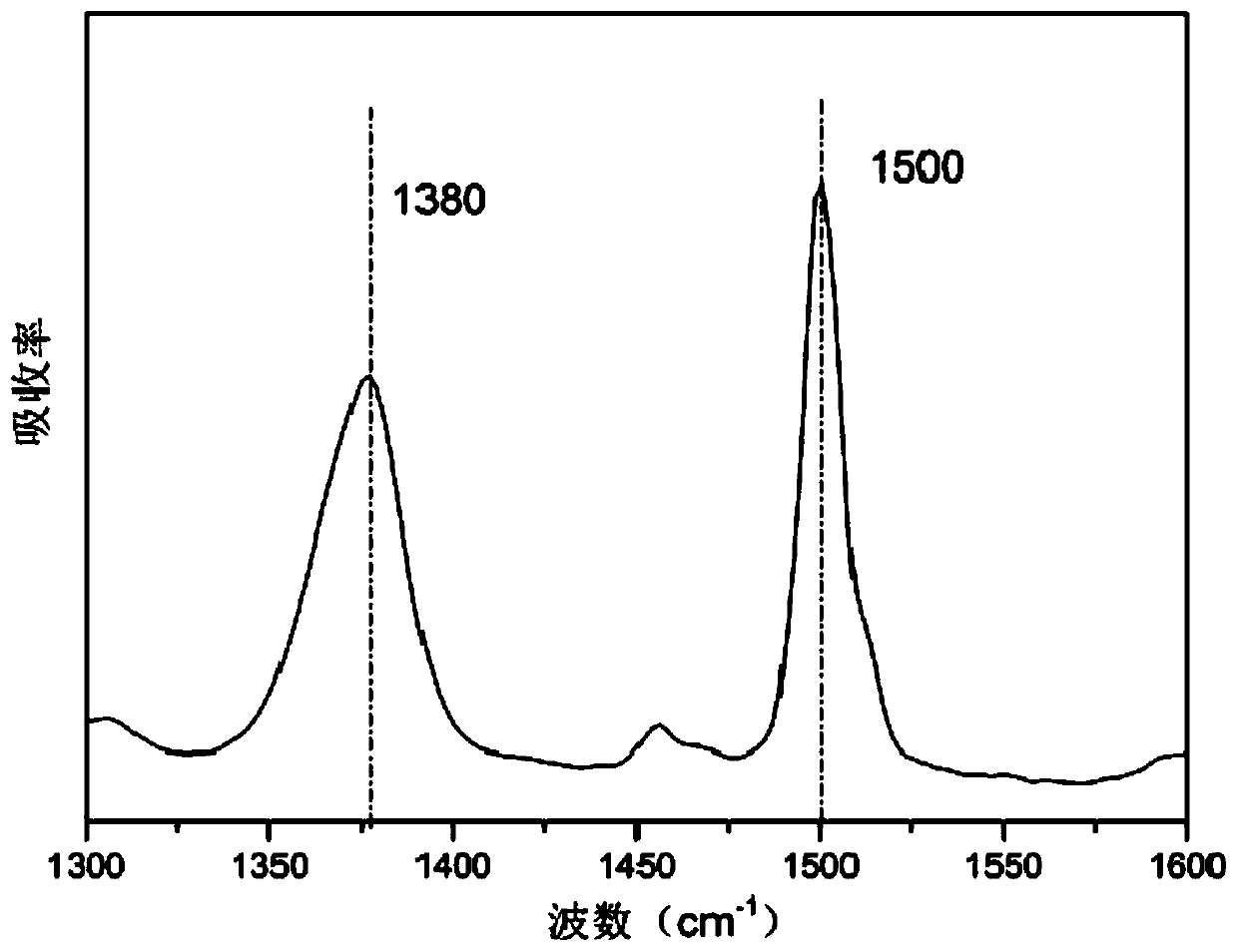

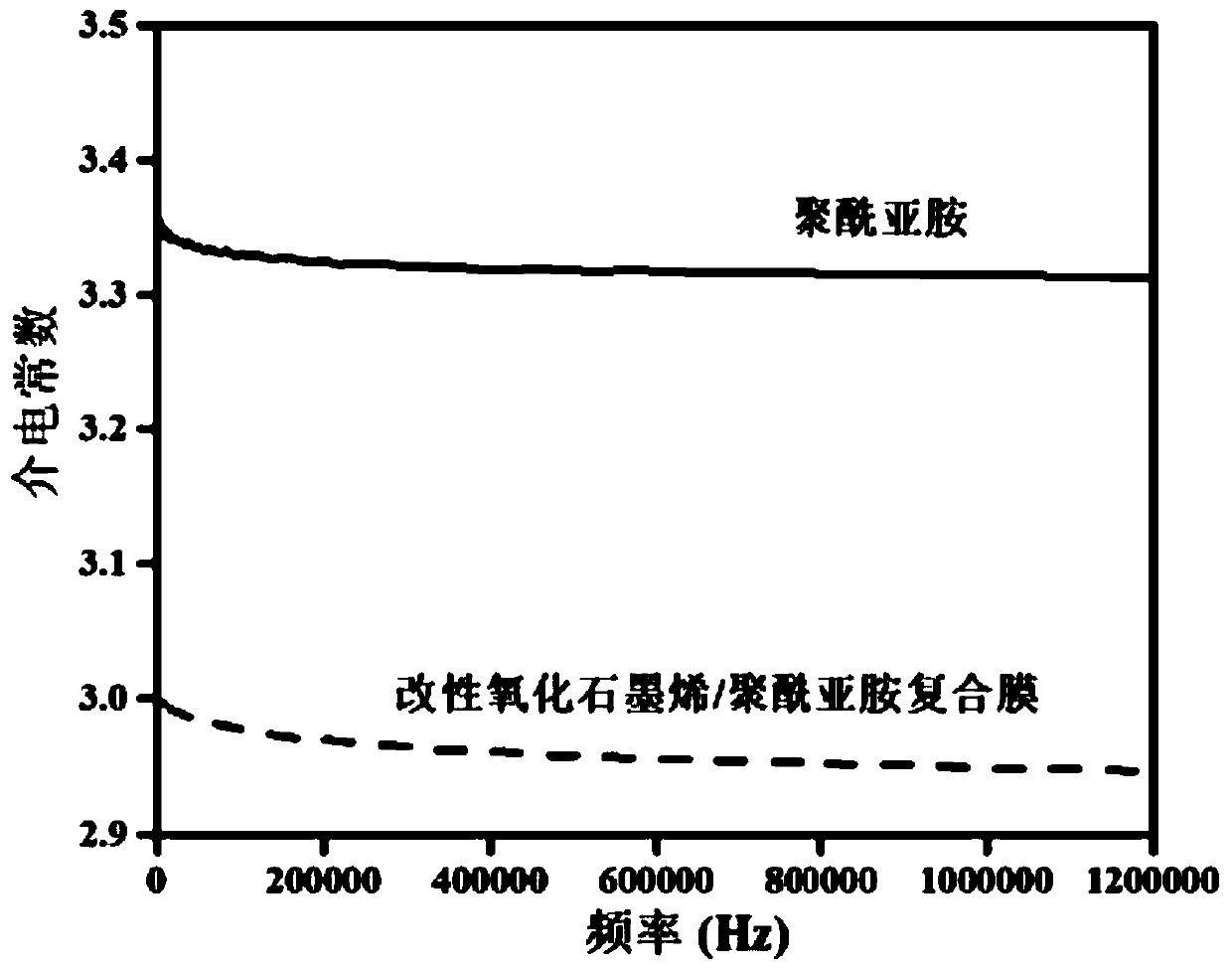

Modified graphene oxide, slurry and composite film, and preparation methods and applications thereof

A technology of composite film and oxide stone, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of polyimide not having low dielectric constant, reduced mechanical properties, high toxicity, etc., to avoid residue Effects of uneven dispersion, simple preparation method, and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

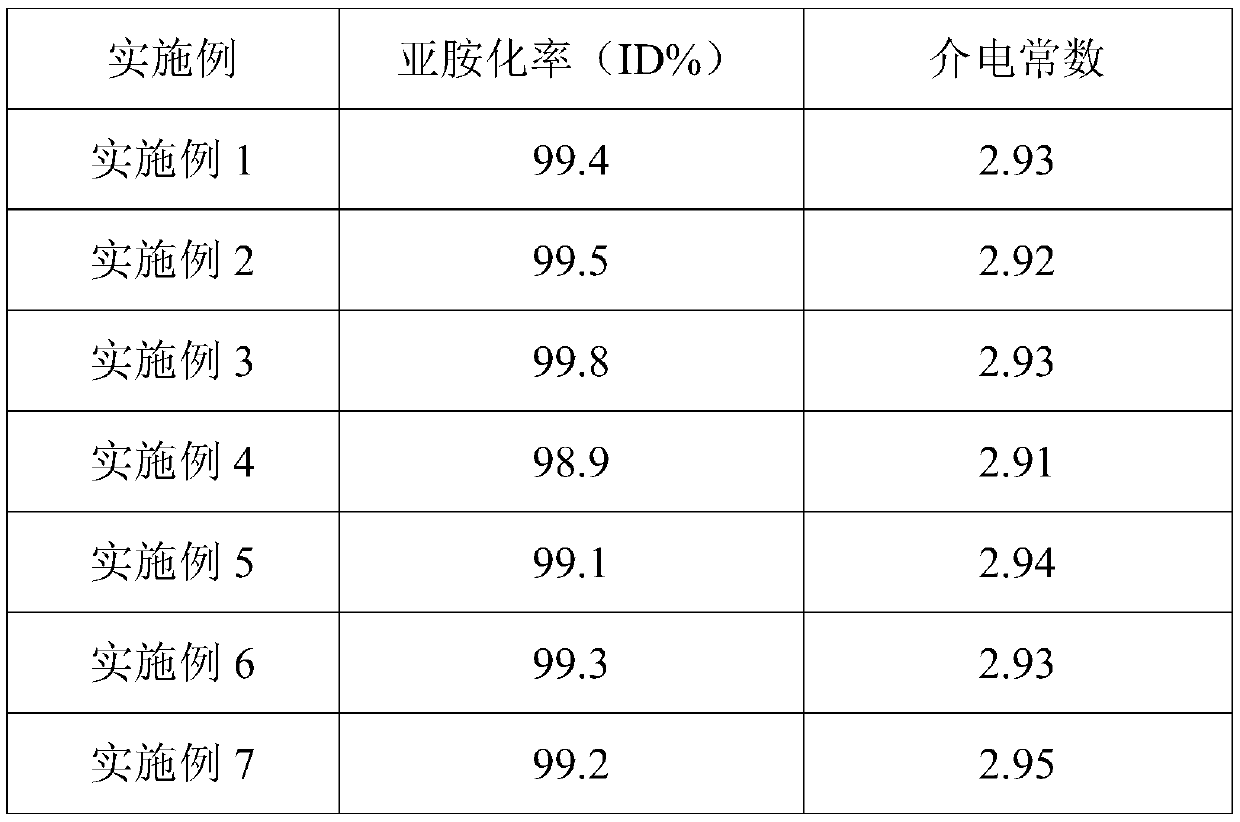

Examples

Embodiment 1

[0072] The present embodiment provides a preparation method for modified graphene oxide, comprising stirring and dissolving 2g of graphite oxide in 200g of polar organic solvent (N-methylpyrrolidone), and adding 2g of curing accelerator (6- Aminoquinoline) and 1 g of dicyclohexylcarbodiimide were reacted for 24 hours at 60°C with magnetic stirring and an inert atmosphere. The corresponding curing accelerator modified graphene oxide (6-aminoquinoline modified graphene oxide) was obtained.

[0073] The present embodiment also provides a kind of preparation method of slurry, comprises the steps:

[0074] (1) At room temperature, under mechanical stirring and an inert atmosphere, dissolve 0.127g of 6-aminoquinoline modified graphene oxide in 114g of N-methylpyrrolidone solvent, until there is no obvious precipitate, then sonicate for 1h, and then Add 6g of 4,4'-diaminodiphenyl ether until completely dissolved, then continue to stir for about 1h to obtain a mixed solution of 6-ami...

Embodiment 2

[0079] The only difference from Example 1 is that the N-methylpyrrolidone used in the slurry preparation process is replaced by N,N-dimethylformamide of the same quality, and the rest of the preparation methods are the same as in Example 1.

Embodiment 3

[0081] The only difference from Example 1 is that the N-methylpyrrolidone used in the slurry preparation process is replaced by N,N-dimethylacetamide of the same quality, and the rest of the preparation methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com