A kind of polyimide resin and its preparation method and a kind of polyimide foam

A technology of polyimide resin and polyimide, which is applied in the field of polyimide materials, can solve the problems of poor mechanical properties and low operating temperature, and achieve long service life, good thermal stability, high imide The effect of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

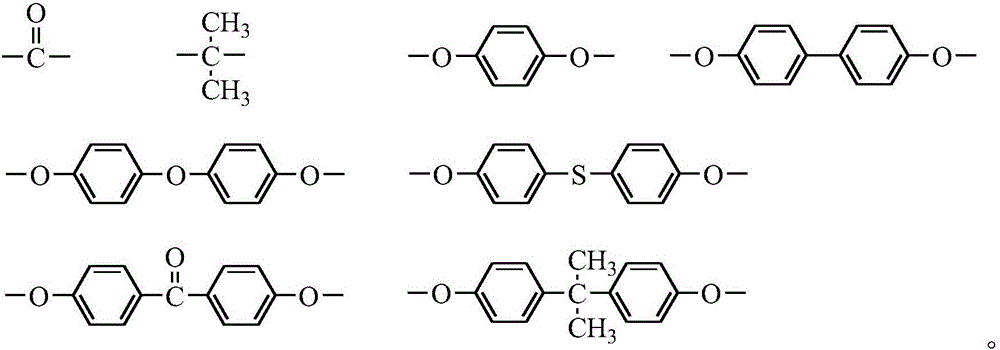

[0027] The present invention also provides a preparation method of the polyimide resin, comprising adding aromatic amine, polylactide, and dianhydride into a solvent, and removing the solvent after reaction to obtain the polyimide resin;

[0028] Wherein, the aromatic amine is or

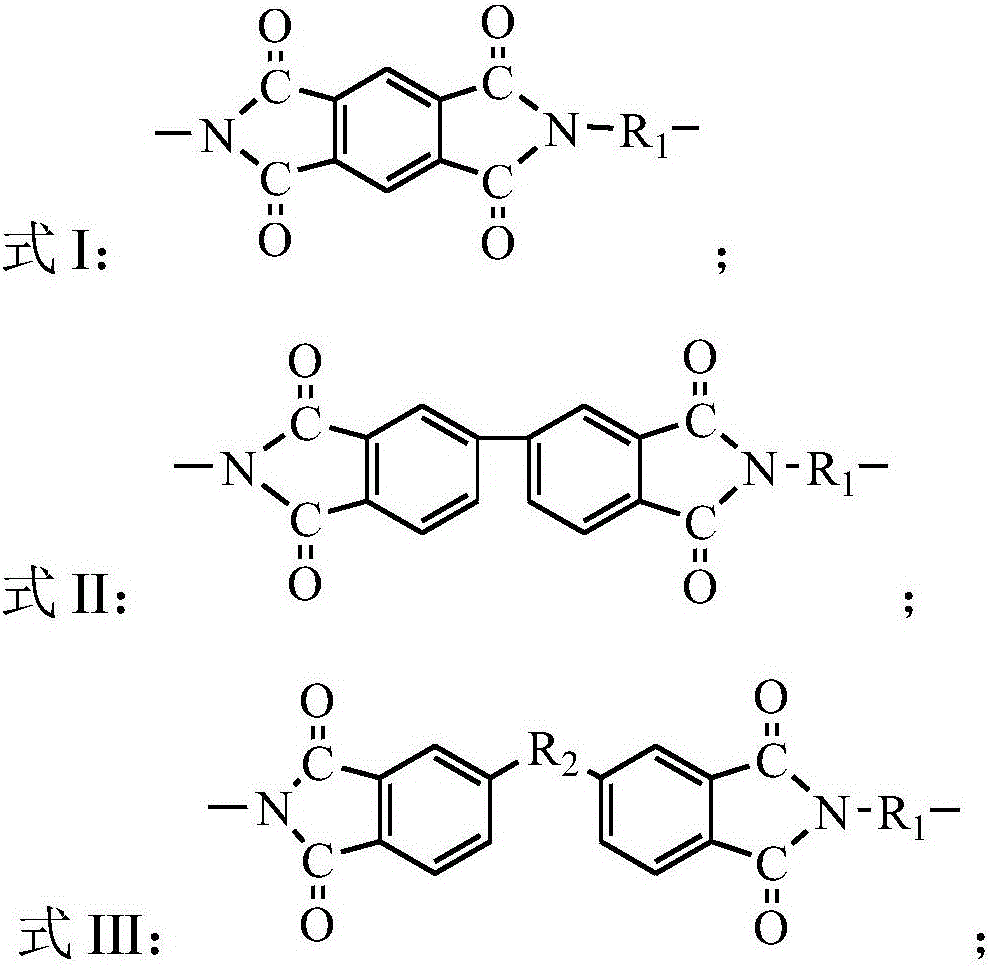

[0029] The dianhydride is (Pyromellitic dianhydride), or

[0030] In the present invention, the aromatic amine preferably adopts Its chemical name is 3,5-diaminobenzoic acid, but it is not limited thereto.

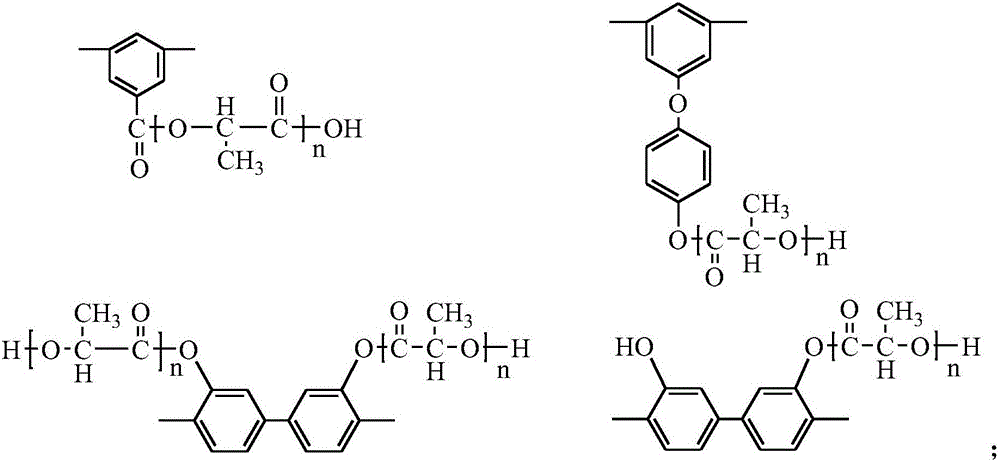

[0031] Polylactide, also known as polylactic acid, has a structural formula of

[0032] According to the preparation method of the present invention, during the reaction, the amino group in the aromatic amine reacts with the acid anhydride group in the dianhydride to form an imide structural unit, and the carboxyl or hydroxyl group that does not participate in the reaction on the aromatic amine continues to react with the polypropylene The lactide undergoes a condensation reactio...

Embodiment 1

[0047] (1) Accurately weigh 233mL of DMF and 167mL of tetrahydrofuran as a mixed solvent and place them in a three-necked flask, add 11.23g of aromatic amine (3,5-diaminobenzoic acid), stir until completely dissolved, then add 30.91g of Dianhydride (3,3',4,4'-benzophenone tetraacid dianhydride) was added slowly and quantitatively in batches, and reacted at room temperature for 3h. Then add 227.1g of polylactide (molecular weight 2538, that is, n=35), that is, the molar ratio of aromatic amine, polylactide and dianhydride is 1:0.87:0.96, and then continue stirring at 80°C for 4h, then Distill under reduced pressure, remove solvent, continue vacuum drying, obtain the pale yellow polyimide resin solid of the present embodiment, denoted as S1, it contains the structural unit shown in formula III, wherein R 1 for n=35, R 2 for

[0048] (2) Crush S1 and press it into thin slices at room temperature, preheat at 120°C for 30 minutes, then heat at 180°C for 5 minutes, raise the te...

Embodiment 2

[0050] The polyimide resin S2 and the polyimide foam S20 of the present embodiment were prepared in the same manner as in Example 1, the difference being:

[0051] In step (1), using As the dianhydride of this embodiment instead of 3,3',4,4'-benzophenone tetraacid dianhydride in Example 1, and aromatic amine, polylactide (molecular weight is 2538, ie n=35) The molar ratio with dianhydride is 1:0.87:1;

[0052] The polyimide resin S2 that obtains by above-mentioned steps, obtains it and contains the structural unit shown in formula II, wherein R 1 for n=35.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com