Preparation method of size-stable polyimide film

A polyimide film, dimensionally stable technology, applied in the field of preparation of dimensionally stable polyimide film, can solve the problems of easy formation of small cracks, pulling fine lines, abnormal matching of longitudinal stretching process parameters, etc. Achieve the effect of improving production yield, reducing production energy consumption, and excellent dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Add 320kg of DMAc solvent in the reactor, then add 9kg of PDA and 25kg of ODA, stir for 0.5h, then add 45.6kg of PMDA (adding in 3 times), react for 5h at normal temperature, and obtain a viscosity of 100pa·s Polyamic acid resin solution; transporting it to a defoaming tank for defoaming to obtain a defoamed polyamic acid resin solution.

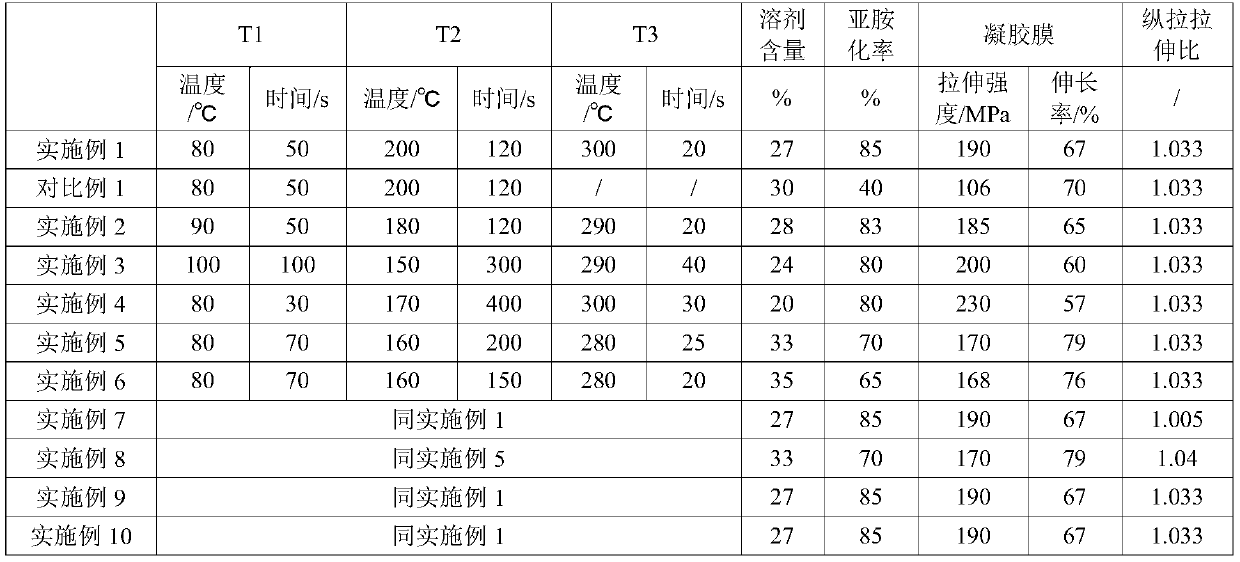

[0036] 2) The polyamic acid resin solution after defoaming is poured through the die to form a liquid film on the steel strip, and the solvent is removed by heating with hot air in the temperature range of T1, T2 and T3, and finally the imide with a solvent content of 27% is obtained. A gel film with a conversion rate of 85%; where,

[0037] T1 temperature is 80°C, and the processing time under T1 temperature condition is 50s; T2 temperature is 200°C, and the processing time under T2 temperature condition is 120s; T3 temperature is 300°C, and the processing time under T3 temperature condition is 20s .

[0038] 3) The resulting ge...

Embodiment 2

[0055] 1) with embodiment 1.

[0056] 2) The polyamic acid resin solution after defoaming is poured through the die to form a liquid film on the steel strip, and the solvent is removed by heating with hot air in the temperature range of T1 and T2 in turn, and finally the solvent content is 28%, and the imidization rate is 28%. is 83% gel film; among them,

[0057] T1 temperature is 90°C; T2 temperature is 180°C; T3 temperature is 290°C.

[0058] 3) with embodiment 1.

[0059] 4) With embodiment 1.

[0060] 5) With embodiment 1.

[0061] For the tensile strength and elongation at break of the obtained longitudinally stretched gel film in step 2) of the present embodiment, the results are shown in Table 1 below.

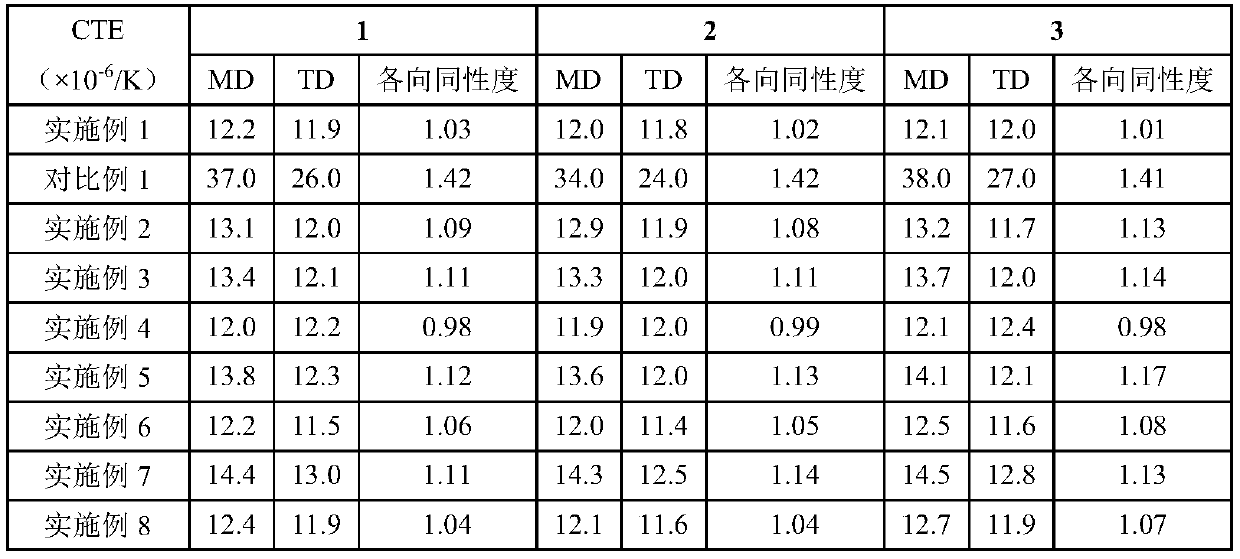

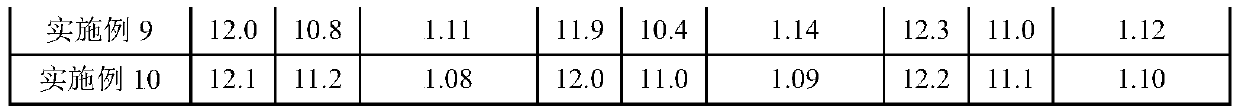

[0062] The CTE (coefficient of thermal expansion) and thermal shrinkage of the film obtained in step 4) of this embodiment were detected, and the results are shown in Table 2 and Table 3 below, respectively.

[0063] The thermal shrinkage rate of the film obtained...

Embodiment 3

[0066] 1) with embodiment 1.

[0067] 2) The polyamic acid resin solution after defoaming is poured through the die to form a liquid film on the steel strip, and the solvent is removed by heating with hot air in the temperature range of T1, T2 and T3 in sequence, and finally the imide with a solvent content of 24% is obtained. A gel film with a conversion rate of 80%; where,

[0068] T1 temperature is 100°C, and the processing time under T1 temperature condition is 100s; T2 temperature is 150°C, and the processing time under T2 temperature condition is 300s; T3 temperature is 290°C, and the processing time under T3 temperature condition is 40s .

[0069] 3) with embodiment 1.

[0070] 4) With embodiment 1.

[0071] 5) With embodiment 1.

[0072] For the tensile strength and elongation at break of the obtained longitudinally stretched gel film in step 2) of the present embodiment, the results are shown in Table 1 below.

[0073] The CTE (coefficient of thermal expansion) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com