Nickel-doped tin oxide nano-material, formaldehyde gas sensor, and preparation method

A nano-material and tin oxide technology, applied in the field of gas sensing, can solve the problems of low formaldehyde response sensitivity, substandard detection limit, high working temperature, etc., achieve great application prospects, reduce preparation costs, and low working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

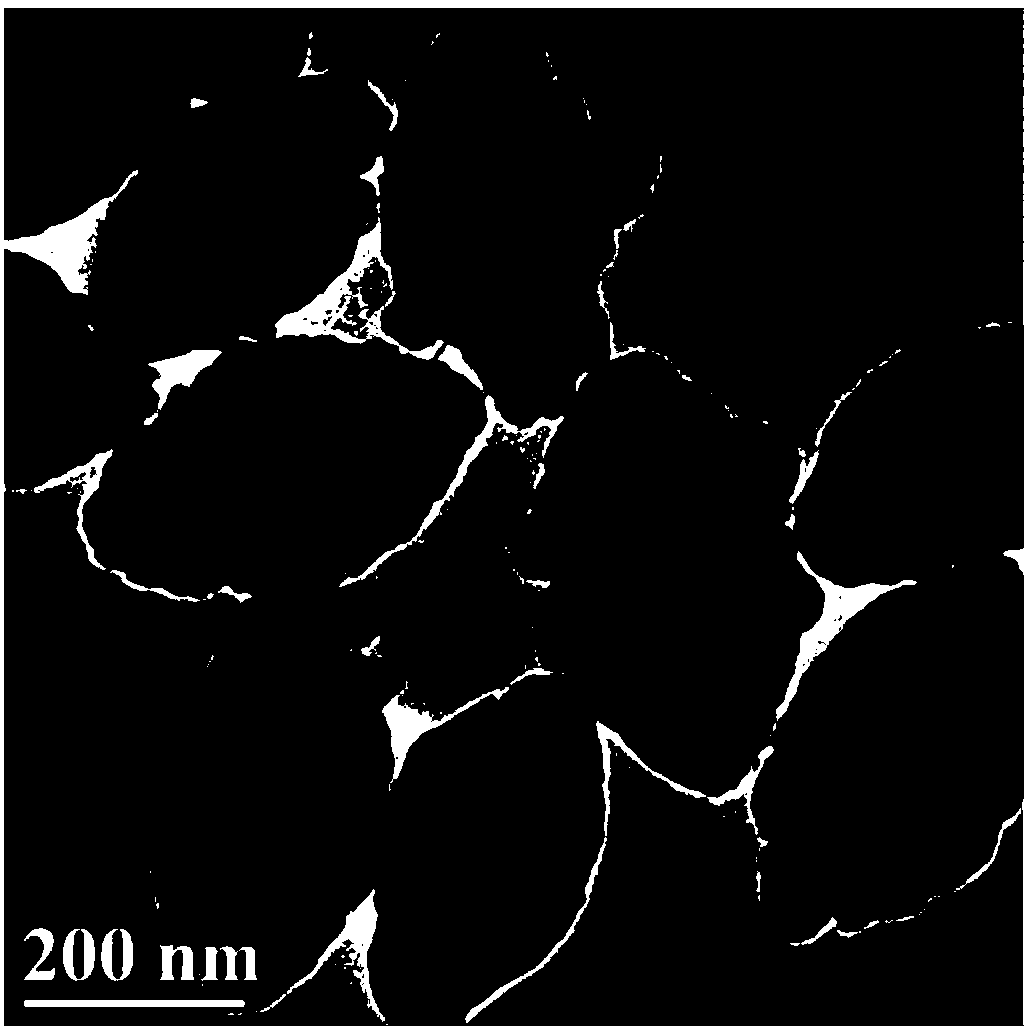

[0060] Embodiment 1, the preparation of nickel-doped tin oxide nanomaterial

[0061] Step 1, weighing 3.0 g of oxalic acid dihydrate and 226 mg of stannous chloride dihydrate (1 mmol) were added to water: 60 mL of anhydrous ethanol mixed solvent of 1:1, stirred until the solid dissolved and the solution became clear;

[0062] Step 2, weighing 11.9 mg of nickel chloride hexahydrate (0.05 mmol) and 1.0 g of polyvinylpyrrolidone into the solution obtained in step 1, and stirring to obtain a mixed solution;

[0063] Step 3, heating the mixed solution obtained in the above steps to 200°C for 12 hours, cooling down to room temperature, washing with deionized water and ethanol alternately, and then centrifuging at a centrifugal speed of 8000rpm for 10min to obtain crude nickel-doped tin oxide nanoparticles ;

[0064] Step 4, dry the crude nickel-doped tin oxide nanoparticles in an oven at 60°C for 24 hours, put the dried solid in a high-temperature crucible, set the muffle furnace t...

Embodiment 2

[0066] Embodiment 2, the preparation of nickel-doped tin oxide nanomaterial

[0067] Step 1, weighing 3.0 g of oxalic acid dihydrate and 226 mg of stannous chloride dihydrate (1 mmol) were added to water: 60 mL of anhydrous ethanol mixed solvent of 1:1, stirred until the solid dissolved and the solution became clear;

[0068] Step 2, weighing 2.4mg of nickel chloride hexahydrate (0.01mmol) and 1.0g of polyvinylpyrrolidone into the solution obtained in step 1, and stirring to obtain a mixed solution;

[0069] Step 3, heating the mixed solution obtained in the above steps to 160°C for 48 hours, cooling down to room temperature, washing with deionized water and ethanol alternately, and then centrifuging at a centrifugal speed of 5000 rpm for 20 minutes to obtain crude nickel-doped tin oxide nanoparticles ;

[0070] Step 4: Dry the crude nickel-doped tin oxide nanoparticles in an oven at 80°C for 18 hours, put the dried solid in a high-temperature crucible, set the muffle furnace...

Embodiment 3

[0071] Embodiment 3, the preparation of nickel-doped tin oxide nanomaterial

[0072] Step 1, weighing 3.0 g of oxalic acid dihydrate and 226 mg of stannous chloride dihydrate (1 mmol) were added to water: 60 mL of anhydrous ethanol mixed solvent of 1:1, stirred until the solid dissolved and the solution became clear;

[0073] Step 2, weighing 6.00 mg of nickel chloride hexahydrate (0.025 mmol) and 1.0 g of polyvinylpyrrolidone into the solution obtained in step 1, and stirring to obtain a mixed solution;

[0074] Step 3: Warm up the mixed solution obtained in the above steps to 240°C for 10 hours, cool down to room temperature, wash alternately with deionized water and ethanol, and then centrifuge at a centrifugal speed of 10,000 rpm for 5 minutes to obtain crude nickel-doped tin oxide nanoparticles ;

[0075] Step 4, dry the crude nickel-doped tin oxide nanoparticles in an oven at 100°C for 5 hours, put the dried solid in a high-temperature crucible, set the muffle furnace t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com