Preparation method of ultrafiltration membrane for improving antibacterial property and anti-fouling performance through modified graphene

An anti-pollution, graphene modification technology, applied in the direction of chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of pollution, microbial pollution, etc., to achieve pollution suppression, convenient preparation, good antibacterial properties The effect of anti-pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a kind of preparation method that contains 0.025% modified graphene polysulfone membrane, and specific steps are as follows:

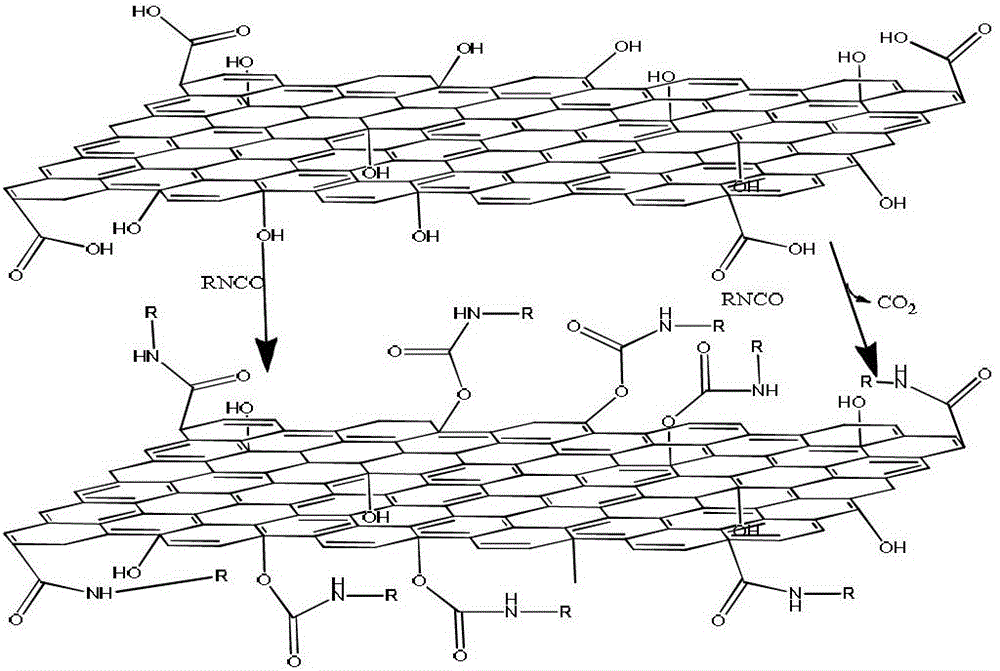

[0046] (1) Add 150mg of graphene oxide and 0.967g of 4-acetylphenylisocyanic acid into 15mL of N-N-dimethylformamide solution respectively, and stir for one day under the protection of nitrogen to form a uniform suspension to make the isocyanate The acidification modification is complete, and then the modified graphene oxide is precipitated with 150mL dichloromethane, collected by filtration with an organic filter membrane with a pore size of 0.22mm, then filtered and rinsed with 50mL dichloromethane, and vacuum-dried at 80°C for 24h to obtain modified graphite alkene;

[0047] (2) Disperse 0.0125g of modified graphene in 40.4875g of N-N dimethylacetamide (DMAC) under ultrasonic conditions, after ultrasonic for 2h, add 0.5g of polyvinylpyrrolidone and 9g of polysulfone to the solution under stirring , after stirring for...

Embodiment 2~4

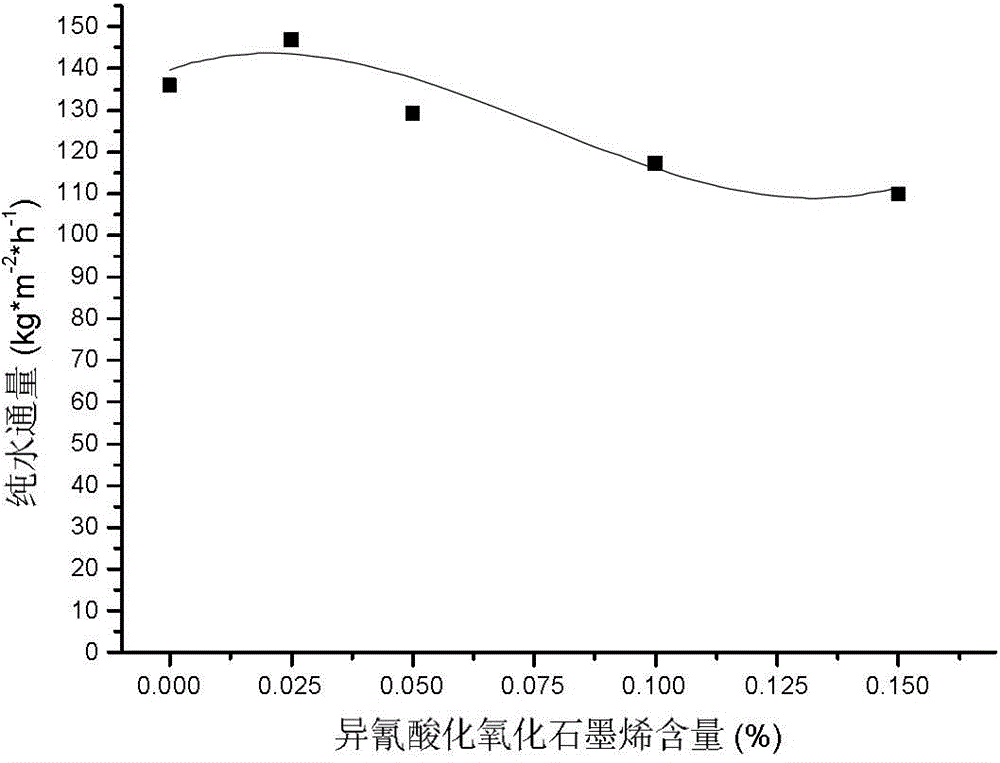

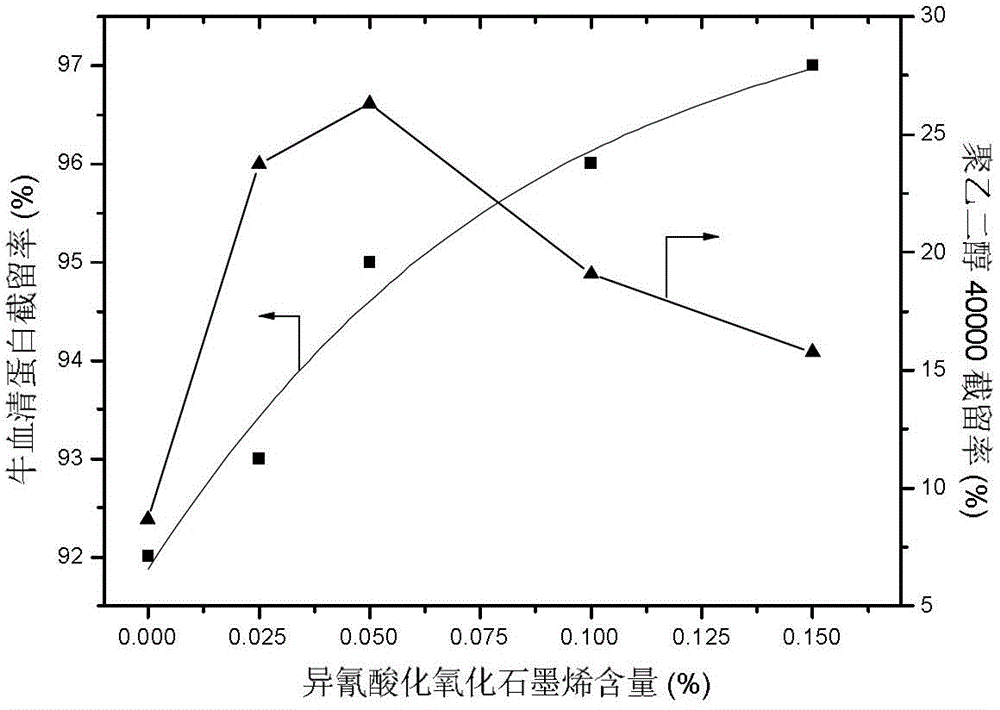

[0063] Only change the content of modified graphene to be 0.05%, 0.10% and 0.15%, other operations are the same as embodiment 1, and the obtained modified graphene polysulfone membrane has different antibacterial and anti-pollution effects, see figure 2 , 3 , 4.

Embodiment 5~8

[0065] The organic solvent in embodiment 1 is changed into a kind of in N-N-dimethylformamide, methylpyrrolidone, dimethylsulfoxide, hexamethylphosphoramide, and other operations are the same as embodiment 1, and the obtained modified graphite The antibacterial effect of vinyl polysulfone membrane is basically the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com