Method for preparing lithium nickel cobalt manganese oxide single-crystal ternary material

A technology for nickel-cobalt lithium manganate and ternary materials is applied in the field of preparing nickel-cobalt lithium manganate single crystal ternary materials, which can solve the problems of difficult industrialized production, complicated preparation process, poor electrochemical performance, etc. The effect of easy control, simple preparation process and stable material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

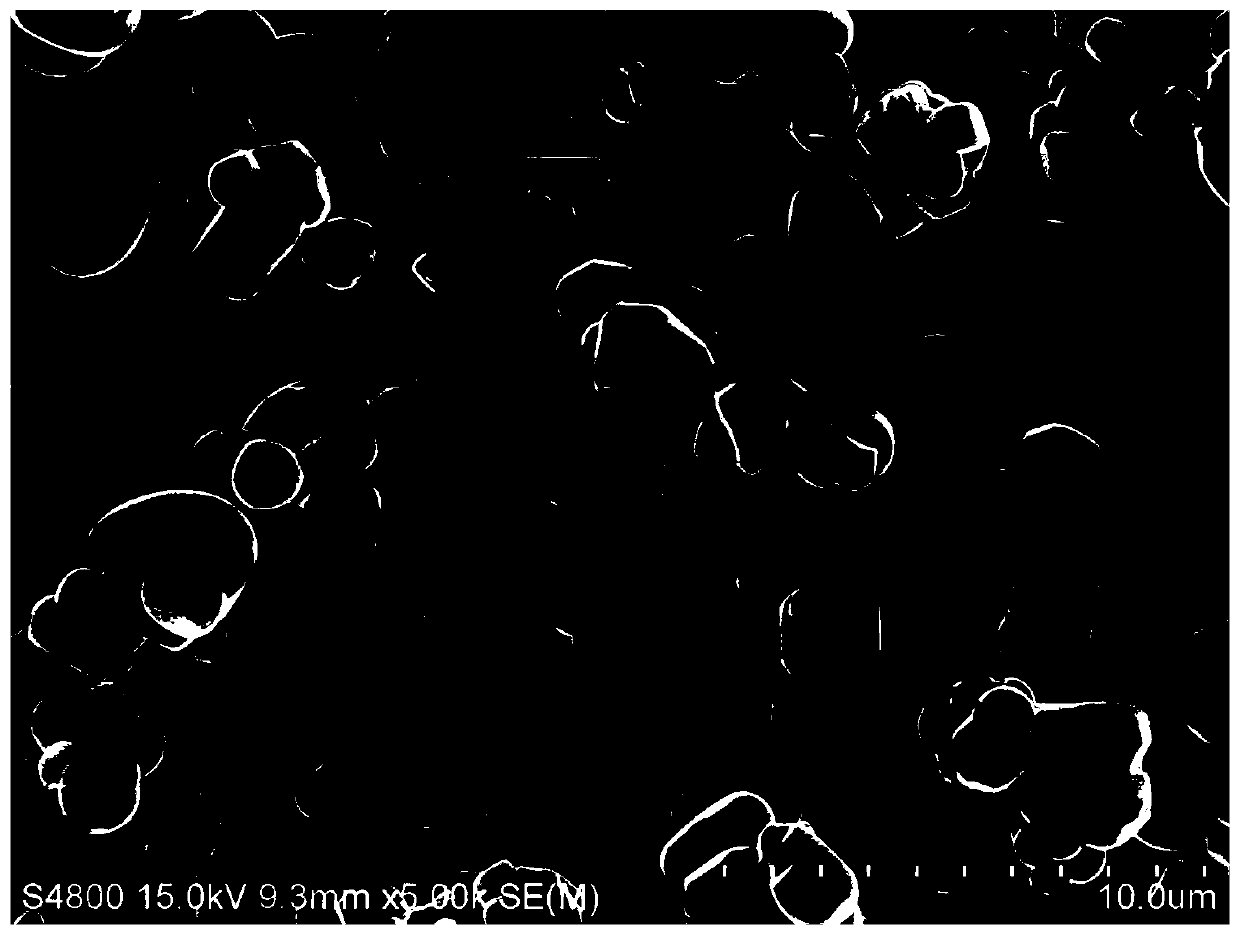

[0059] The preparation process of nickel cobalt lithium manganate single crystal ternary material A1 is as follows:

[0060] (1) The average particle size D 50 3.55μm spherical precursor (Ni 0.5 co 0.2 mn 0.3 )OH and average particle size D 50 10.44μm battery grade lithium carbonate according to Li:Ni 0.5 co 0.2 mn 0.3 =1.06:1 carries out proportioning, adds nanoscale zirconia (average particle diameter is 60nm) simultaneously, makes the mass content of zirconium in the mixture be 0.17% of the total mass of mixture;

[0061] (2) transfer the compound obtained in step (1) into a VC mixer and carry out dry mixing, the VC mixer rotating speed is 600rpm, and the mixing time is 50min, and no white spots can be observed in the mixing state;

[0062] (3) Put the mixed material obtained in step (2) into a sagger, place it in a box furnace, and heat it at a constant temperature of 955°C for 12 hours in an air atmosphere to carry out the roasting reaction. After the sintering is ...

Embodiment 2

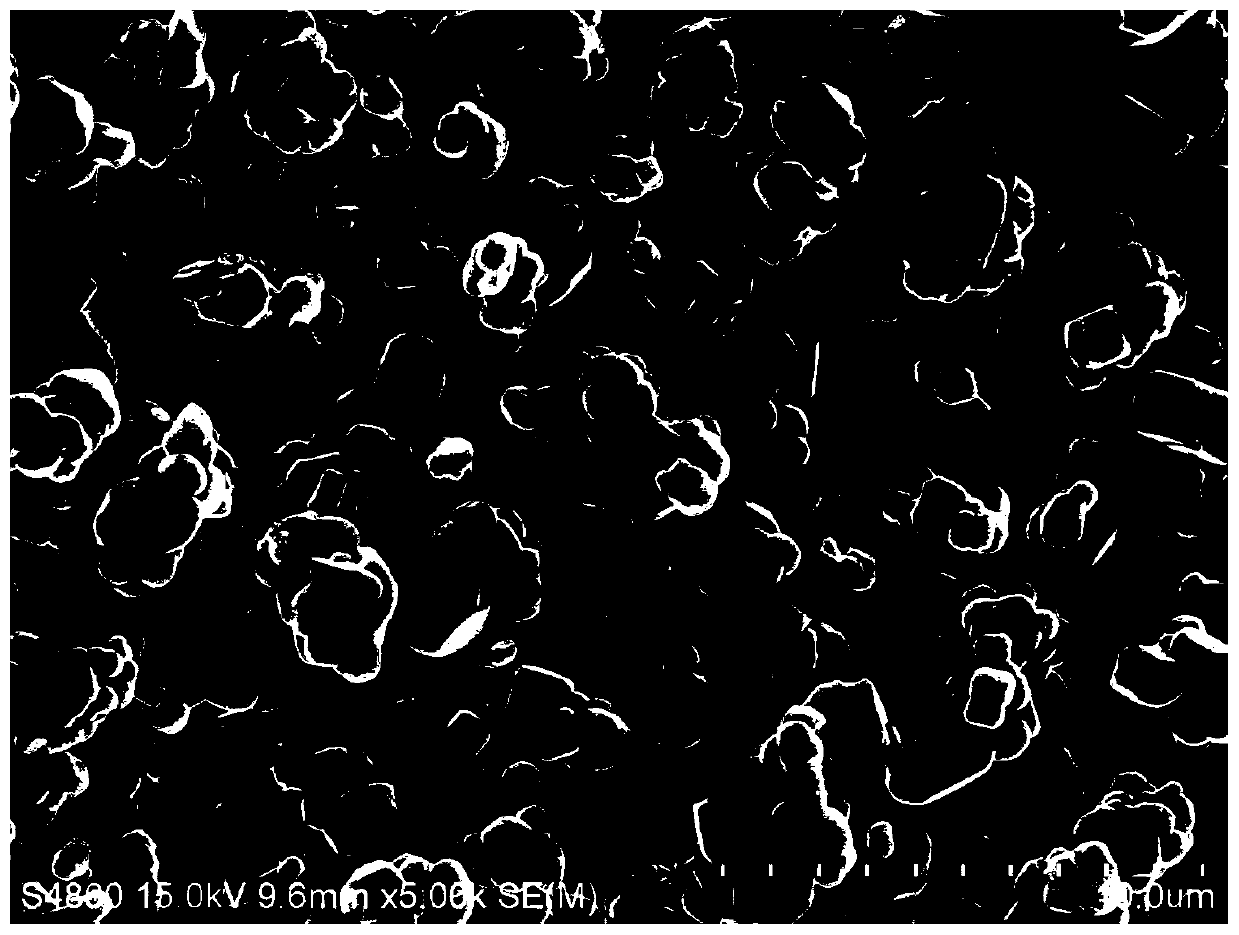

[0065] The preparation process of nickel cobalt lithium manganate single crystal ternary material A2 is as follows:

[0066] (1) The average particle size D 50 3.45μm spherical precursor (Ni 0.5 co 0.2 mn 0.3 )OH and average particle size D 50 11.44μm battery grade lithium carbonate according to Li:Ni 0.5 co 0.2 mn 0.3 =1.06:1 carries out proportioning, adds nanoscale zirconia (average particle diameter is 80nm) simultaneously, makes the mass content of zirconium in the mixture be 0.17% of the total mass of mixture;

[0067] (2) transfer the compound obtained in step (1) into a VC mixer and carry out dry mixing, the VC mixer rotating speed is 650rpm, the mixing time is 45min, and no white spots can be observed in the mixing state;

[0068] (3) Put the mixed material obtained in step (2) into a sagger, place it in a box-type furnace, and heat it at a constant temperature of 952°C for 13 hours in an air atmosphere to carry out the roasting reaction. After the sintering is...

Embodiment 3

[0071] The preparation process of nickel cobalt lithium manganate single crystal ternary material A3 is as follows:

[0072] (1) The average particle size D 50 3.44μm spherical precursor (Ni 0.5 co 0.2 mn 0.3 )OH and average particle size D 50 10.48μm battery grade lithium carbonate according to Li:Ni 0.5 co 0.2 mn 0.3 =1.06:1 carries out proportioning, adds nanoscale zirconia (average particle diameter is 50nm) simultaneously, makes the mass content of zirconium in the mixture be 0.17% of the total mass of mixture;

[0073] (2) transfer the compound obtained in step (1) into a VC mixer and carry out dry mixing, the VC mixer rotating speed is 550rpm, and the mixing time is 55min, and no white spots can be observed in the mixing state;

[0074] (3) Put the mixture obtained in step (2) into a sagger, place it in a box furnace, and heat it at a constant temperature of 957°C for 11 hours in an air atmosphere to carry out the roasting reaction. After the sintering is complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com