Method for catalytically reducing selenium

The technology of reducing agent and catalyst is applied in the field of reducing hexavalent selenium to elemental selenium, and achieves the effects of easy industrial production and application, mild conditions and short reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of method of catalytic reduction selenium of the present invention, concrete steps are as follows:

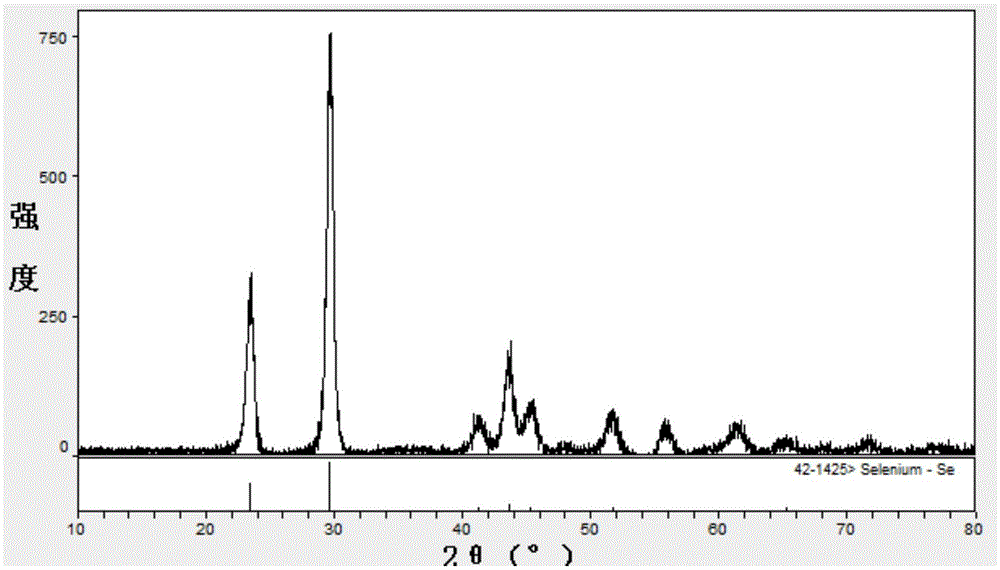

[0027] Sodium selenate (Na 2 SeO 4 ) is dissolved in ultrapure water and is prepared into a sodium selenate solution, so that the selenium content in the solution is 1g / L, and the initial pH of the solution is 2, and 100mL of the solution is taken, and 15mL of analytically pure hydrogen peroxide is added with a constant flow pump, and after mixing evenly, feed Industrial-grade sulfur dioxide gas (gas flow rate is 1L / min), while using a water bath to control the temperature of the reaction system is 60 ° C, reacted for 2 hours, filtered and detected the remaining selenium content in the solution, the final selenium reduction rate was 99.97%, and the reduced solid product was carried out X-ray diffraction detection (such as figure 1 shown), scanning electron microscope detection and inductively coupled plasma atomic emission spectrometry detection results (see Tab...

Embodiment 2

[0029] A kind of method of catalytic reduction selenium of the present invention, concrete steps are as follows:

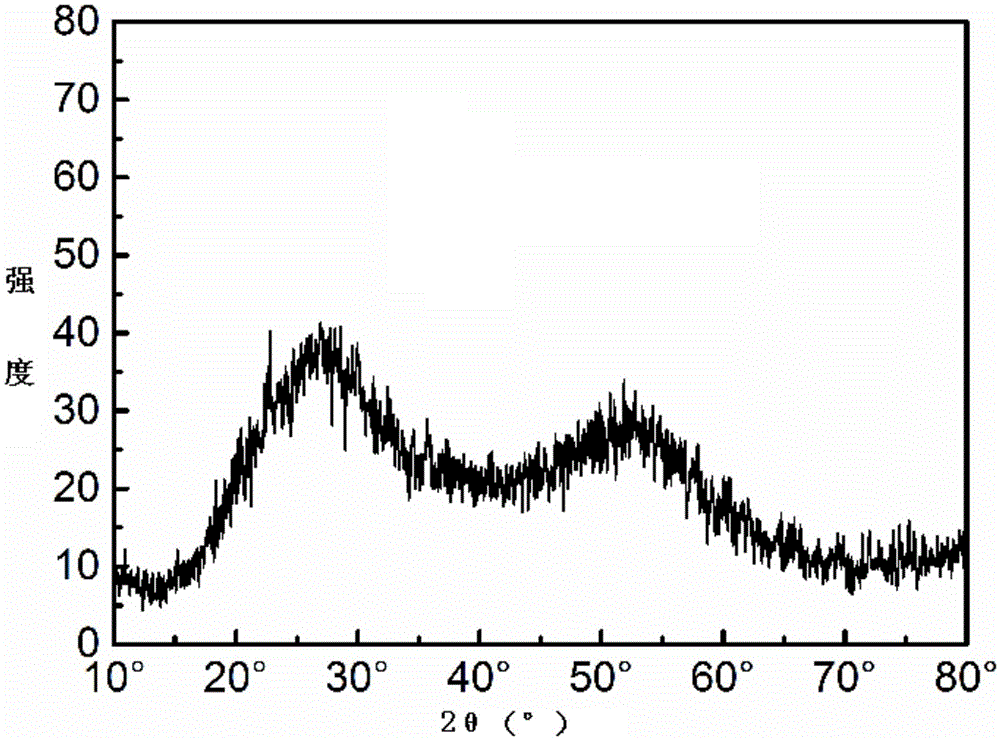

[0030] Sodium selenate (Na 2 SeO 4 ) is dissolved in ultrapure water and prepared as a sodium selenate solution, making the selenium content 1g / L, adjusting the initial pH of the solution=2, taking 100mL of the solution, adding 15mL of analytically pure hydrogen peroxide with a constant flow pump, and feeding into industrial grade sulfur dioxide after mixing Gas (the gas flow rate is 1L / min), while using an ice-water bath to control the temperature of the reaction system to be 0°C, react for 2 hours, detect the remaining selenium content in the solution after filtration, calculate the selenium reduction rate to be 99.89%, and carry out X-ray diffraction on the solid product detection (such as figure 2 shown), scanning electron microscope detection and inductively coupled plasma atomic emission spectrometry detection results (see Table 1), as can be seen from Ta...

Embodiment 3

[0032] A kind of method of catalytic reduction selenium of the present invention, concrete steps are as follows:

[0033] Take 1L of wastewater containing hexavalent selenium from a smelter, in which the concentration of selenium is 5.5g / L, and other impurities include arsenic ions, sodium ions, chromium ions and organic matter. After adding excess hydrogen peroxide 500mL to decompose impurities such as organic matter therein, add 30g sodium sulfite, control the temperature in a water bath at 50°C, filter after 2 hours of reaction, detect the remaining selenium content in the solution, and calculate the selenium reduction rate to be 97.87%. The X-ray detection result of selenium element is the same as that of Example 1, and the detection result of inductively coupled plasma atomic emission spectrometry is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com