Method for separating sweet tea polysaccharide by ultrafiltration membranes

An ultrafiltration membrane and a technology for sweet tea, applied in the field of separation and extraction of tea polysaccharides, can solve the problems of complex steps, high cost, energy consumption and ethanol consumption, etc., and achieve the effects of no environmental pollution, simple steps and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

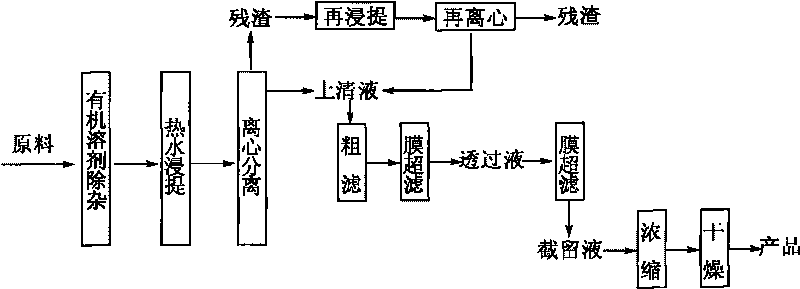

[0023] Weigh 1 kg of sweet tea, crush it to 20 mesh, add ethanol:ether=1:1 mixed liquid (solid-liquid ratio is 1:10) degreasing, depigmentation and tea polyphenols and other components, filter the filter residue and add 5 times the temperature of the volume For distilled water at 80°C, cover and soak for 40 minutes and then filter; add 5 times the volume of distilled water at 85°C to the filter residue and soak for 30 minutes before filtering; add 3 times the volume of distilled water at 90°C to soak for 30 minutes Then filter; combine the extracts, centrifuge the extracts at 4000r / min for 10min, take the supernatant, and then filter with a 0.2μm microfiltration membrane. After the two-step purification process of centrifugation and filtration, the extract has preliminarily removed macromolecular substances such as fine dust, crude fiber, and colloid in the extract. The sweet tea polysaccharide extract is sequentially ultrafiltered through ultrafiltration membrane devices with...

Embodiment 2

[0025] Weigh 1 kg of sweet tea, crush it to 20 mesh, add ethanol: water = 4: 1 mixed solution (solid-liquid ratio is 1: 10), boil for 60 minutes, cool and filter; boil for the second and third times for 30 minutes to combine the extract, and recover under reduced pressure Ethanol, and the rest of the steps were the same as in Example 1 to obtain 11.35 g of a light green polysaccharide sample, the mass fraction of tea polysaccharide was 85.2%, and the yield accounted for 1.75% of the dry weight of tea leaves.

Embodiment 3

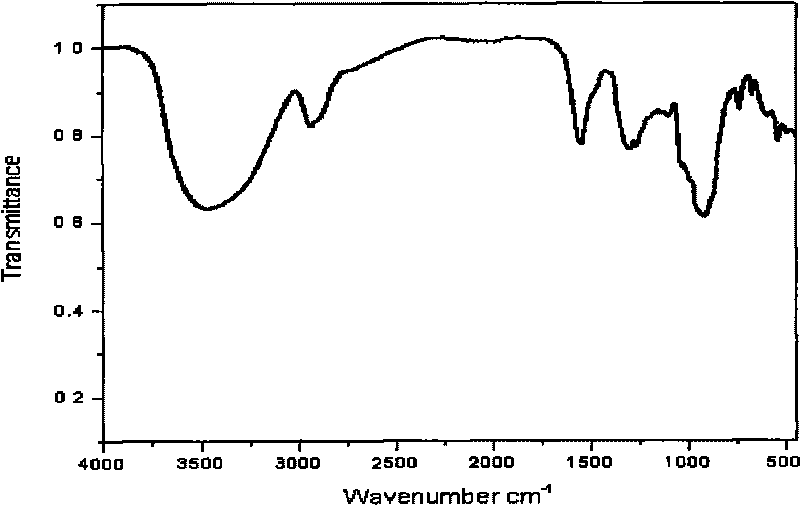

[0027] Infrared analysis test result of sweet tea polysaccharide obtained in embodiment 1 shows that, 3200-3600cm -1 At the O-H stretching vibration peak, 2790-3000cm -1 It is the C-H absorption peak, these two groups of peaks are the general characteristic absorption peaks of polysaccharides, 1750cm -1 It is the stretching vibration peak of -C=O, 1100cm -1 The stretching vibration peak of C-O-C indicates that the obtained sweet tea polysaccharide is mainly composed of pyranose rings. Infrared results such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com