Heat exchanger with twisted sheet

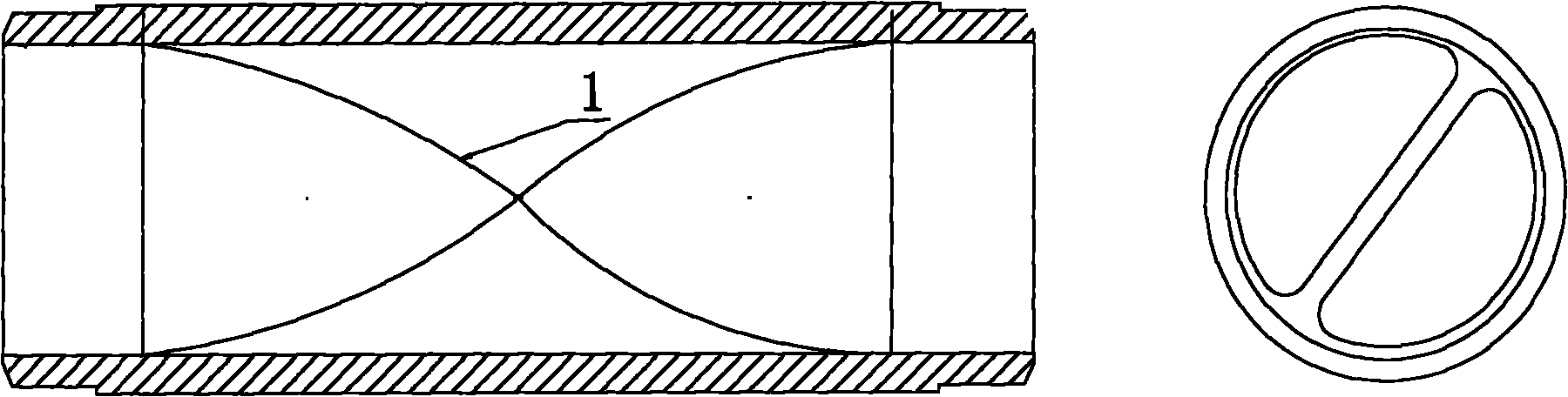

A twisted sheet and heat exchanger technology, applied in the field of heat exchangers, can solve the problems of high cost and difficulty in processing and manufacturing, and achieve the effects of reducing the rate of fouling, thinning the original boundary layer, and intensifying the severity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

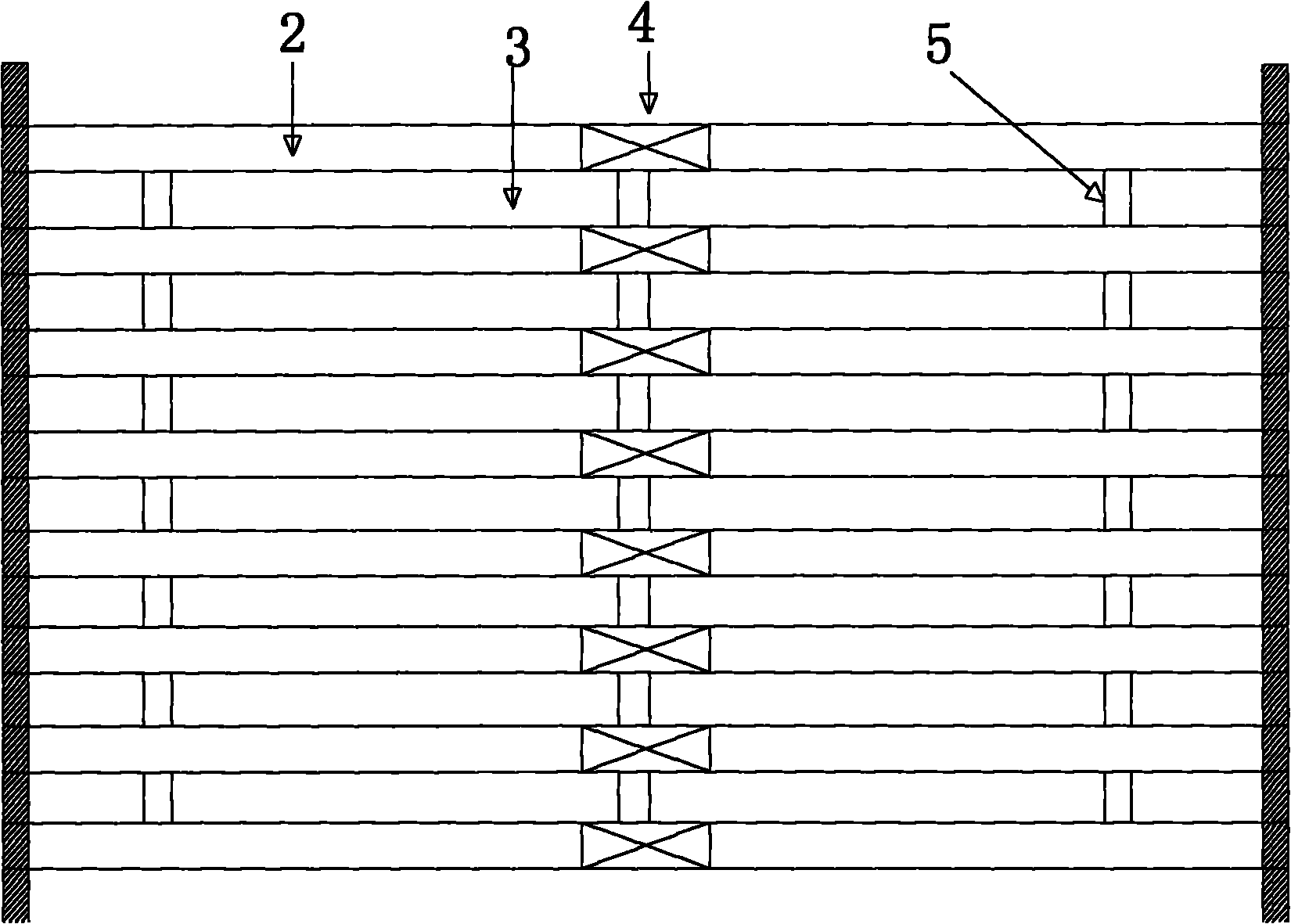

[0030] In this embodiment, the tube-and-tube heat exchanger is taken as an example. figure 2 It is a simplified schematic diagram of the shell and tube heat exchanger. Tube and tube heat exchanger is currently the most widely used heat transfer equipment in chemical production. The main advantage is that the heat transfer area per unit volume is large and the heat transfer effect is good; The advantages of large operating flexibility.

[0031] Next, select one section of the heat exchanger for calculation, its size and parameters are shown in Table 1, and the process parameters are shown in Table 2.

[0032] Table 1 Structural diagram of shell and tube heat exchanger

[0033]

[0034] Set or not set the twisted sheet in the heat exchange tube of the shell and tube heat exchanger, and carry out the heat transfer calculation of the two cases, and the calculation results are shown in Table 2:

[0035] Table 2 Process parameters of shell and tube heat exchanger

[0036] ...

Embodiment 2

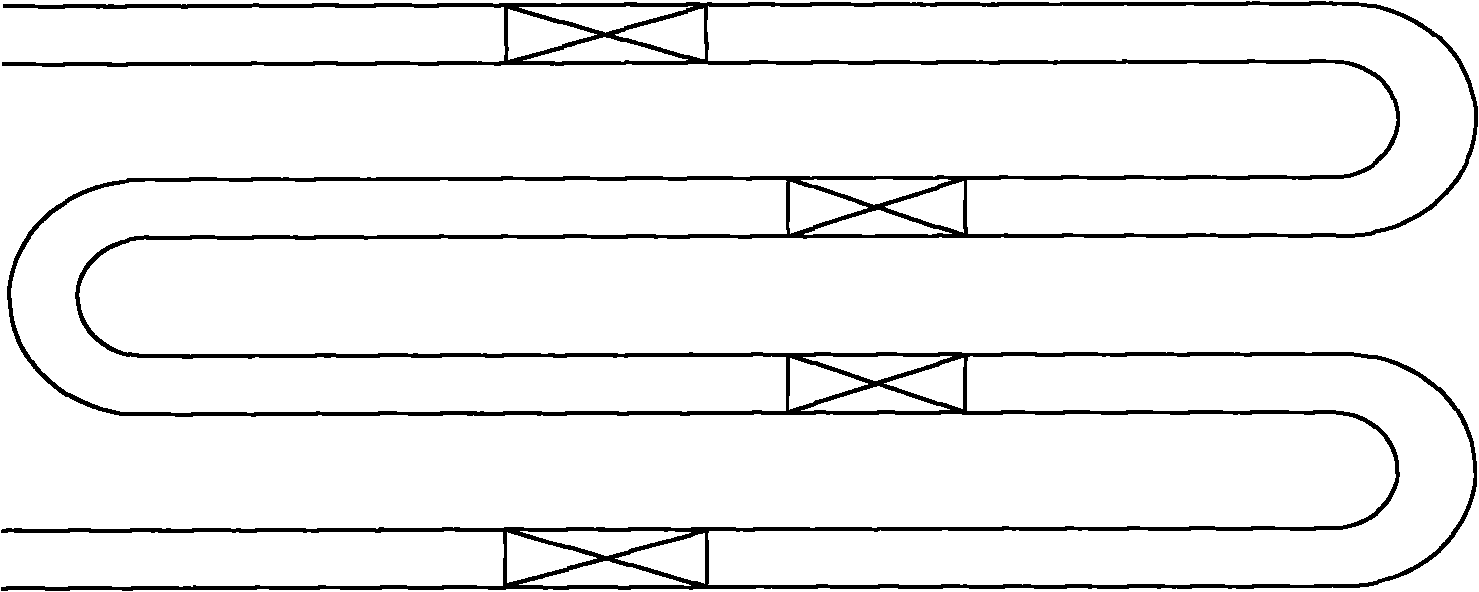

[0038] This embodiment takes the coiled tube heat exchanger as an example, image 3 It is a simple structural diagram of a coiled tube heat exchanger. As the name suggests, the snake-tube heat exchanger is made of bent metal pipes, which resembles a snake. The advantages of this type of heat exchanger are simple structure, low price, easy corrosion resistance, and ability to withstand high pressure. Next, select a part of the tube section for calculation, its size and parameters are shown in Table 3, and the process parameters are shown in Table 4.

[0039] Table 3 Structural diagram of coiled tube heat exchanger

[0040] project

content

Remark

Tube length (mm)

9128.4

steel material

Tube inner diameter (mm)

40

Tube wall thickness (mm)

5

Number of heat exchanger positions

3

Twist Ratio of Heat Exchanger

2.5

Twist angle of heat exchanger

180°

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com