Process for deeply treating and recycling high-salinity industrial waste water

A technology for advanced treatment of industrial wastewater, applied in the field of environmental protection and comprehensive utilization of resources, can solve the problems of low concentration multiple, microbial pollution, low recovery rate, etc., and achieve the effect of prolonging the cleaning cycle and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

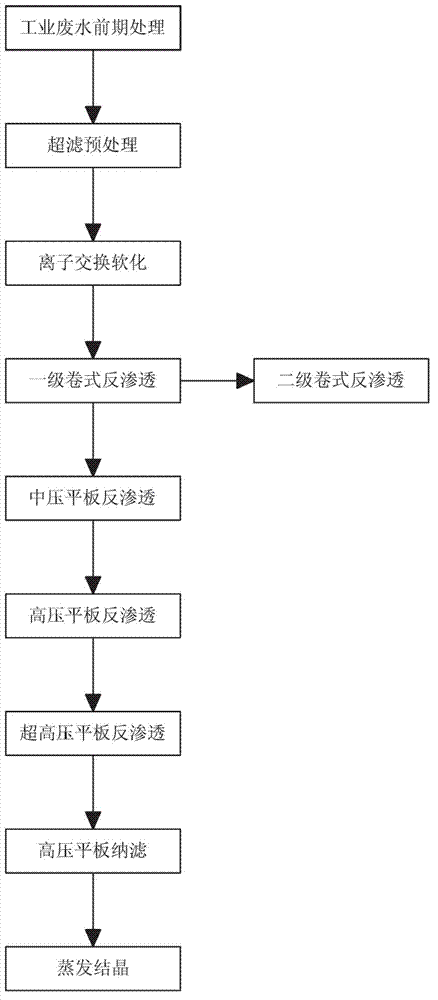

Image

Examples

Embodiment

[0069] A company's chemical and pharmaceutical wastewater is 1,500 tons / day, including 500 tons / day of high-concentration wastewater, 600 tons / day of low-concentration wastewater, and 400 tons / day of other wastewater.

[0070] Water quality status of high-concentration wastewater: COD Cr 25000 mg / L, B / C=0.2, NH 3 -N1500 mg / L, SS 500 mg / L, Cl - 5000 mg / L, total salt content 35000 mg / L, petroleum 370 mg / L, PH 10.

[0071] Water quality status of low-concentration wastewater: COD Cr 1000 mg / L, NH 3 -N 50 mg / L, SS 200 mg / L, full salt 1500mg / L, PH 7.

[0072] After oil separation→coagulation sedimentation→air flotation→hydrolysis→oxidation ditch→ozone oxidation→sand filtration and other processes, the actual water quality status: water temperature 25 ℃, PH9, CODcr: 150mg / L, SS≤50mg / L, NH 3 -N- 1830 mg / L, SO 4 2- 3050mg / L, total hardness 5.5mmol / L, total dissolved solids (TDS) 6500mg / L.

[0073] Now it is necessary to reuse the biochemically treated wastewater after adv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com