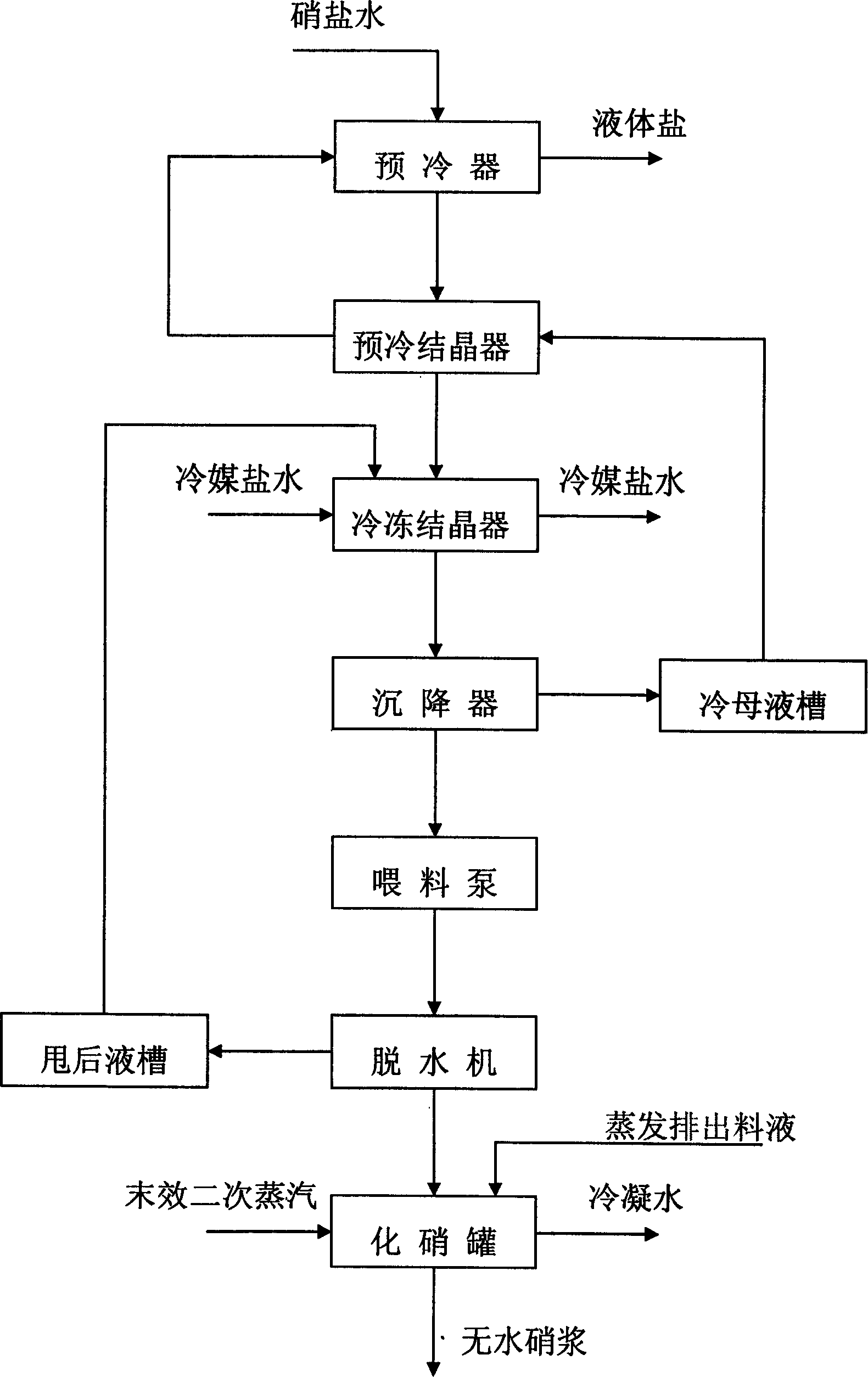

Process for preparing anhydrous mirabilite by freezing method

An anhydrous nitrate and freezing technology, applied in the chemical industry, sustainable manufacturing/processing, alkali metal sulfite/sulfate dehydration, etc., can solve the problems of high energy consumption and unstable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

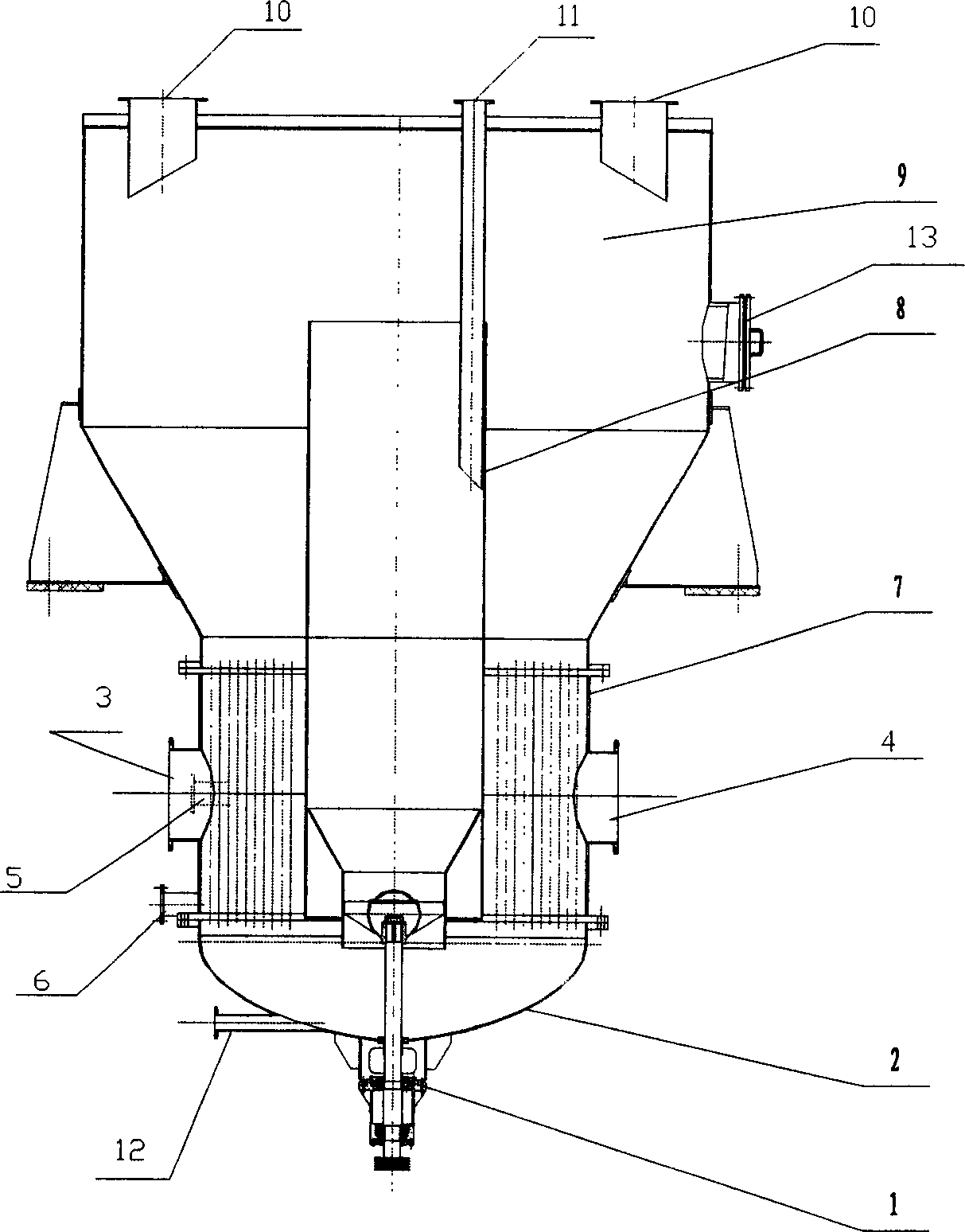

Method used

Image

Examples

Embodiment 1

[0019] The nitrate-containing solution with a mass concentration of 70g / l is preliminarily cooled to 10°C by using the cold mother liquor as a refrigerant through a precooler. Then transfer the feed liquid to the pre-cooling crystallizer. The refrigerant of the pre-cooling crystallizer uses the cold mother liquor with a temperature of -4°C to freeze the feed liquid for a period of time. After that, it enters the frozen crystallizer for the second stage of freezing and analyzing nitrate. The refrigerant of the frozen crystallizer is the frozen calcium chloride brine with a temperature of -10°C provided by the refrigeration process to freeze the feed liquid to -6°C, and the calcium chloride brine is discharged from the refrigeration system. The frozen feed liquid enters the settler for solid-liquid separation. The cold mother liquor overflowing from the settler is used as the refrigerant for the pre-cooling crystallizer and the pre-cooler successively in two steps. It then ex...

Embodiment 2

[0021] The nitrate-containing solution with a mass concentration of 65g / l is preliminarily cooled to 15°C by using the cold mother liquor as a refrigerant through a precooler. Then transfer the feed liquid to the pre-cooling crystallizer. The refrigerant of the pre-cooling crystallizer uses the cold mother liquor with a temperature of -5°C to freeze the feed liquid for a period of time. After that, it enters the frozen crystallizer for the second stage of freezing and analyzing nitrate. The refrigerant of the frozen crystallizer is the frozen calcium chloride brine with a temperature of -8°C provided by the refrigeration process to freeze the feed liquid to -5°C, and the frozen calcium chloride brine is discharged out of the refrigeration system. The frozen feed liquid enters the settler for solid-liquid separation. The cold mother liquor overflowing from the settler is used as the refrigerant for the pre-cooling crystallizer and the pre-cooler successively in two steps. It...

Embodiment 3

[0023] The nitrate-containing solution with a mass concentration of 65g / l is preliminarily cooled to 20°C by using the cold mother liquor as a refrigerant through a precooler. Then transfer the feed liquid to the pre-cooling crystallizer. The refrigerant of the pre-cooling crystallizer uses the cold mother liquor with a temperature of -5°C to freeze the feed liquid for a period of time. After that, it enters the frozen crystallizer for the second stage of freezing and analyzing nitrate. The refrigerant of the frozen crystallizer is the temperature provided by the refrigeration process. The calcium chloride brine is frozen at -12°C to freeze the feed liquid to -7°C, and the calcium chloride brine is discharged from the refrigeration system. The frozen feed liquid enters the settler for solid-liquid separation. The cold mother liquor overflowing from the settler is used as the refrigerant for the pre-cooling crystallizer and the pre-cooler successively in two steps. It then e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com