Rotary membrane separation device and application thereof

A membrane separation, rotary technology, applied in semi-permeable membrane separation, membrane technology, water/sludge/sewage treatment, etc., can solve the problems of inconvenient operation of membrane separation, influence of separation performance, small pressure loss, etc., to improve membrane Blockage and reduced membrane flux, extended cleaning cycle and lifetime, avoidance of deposits and blockage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

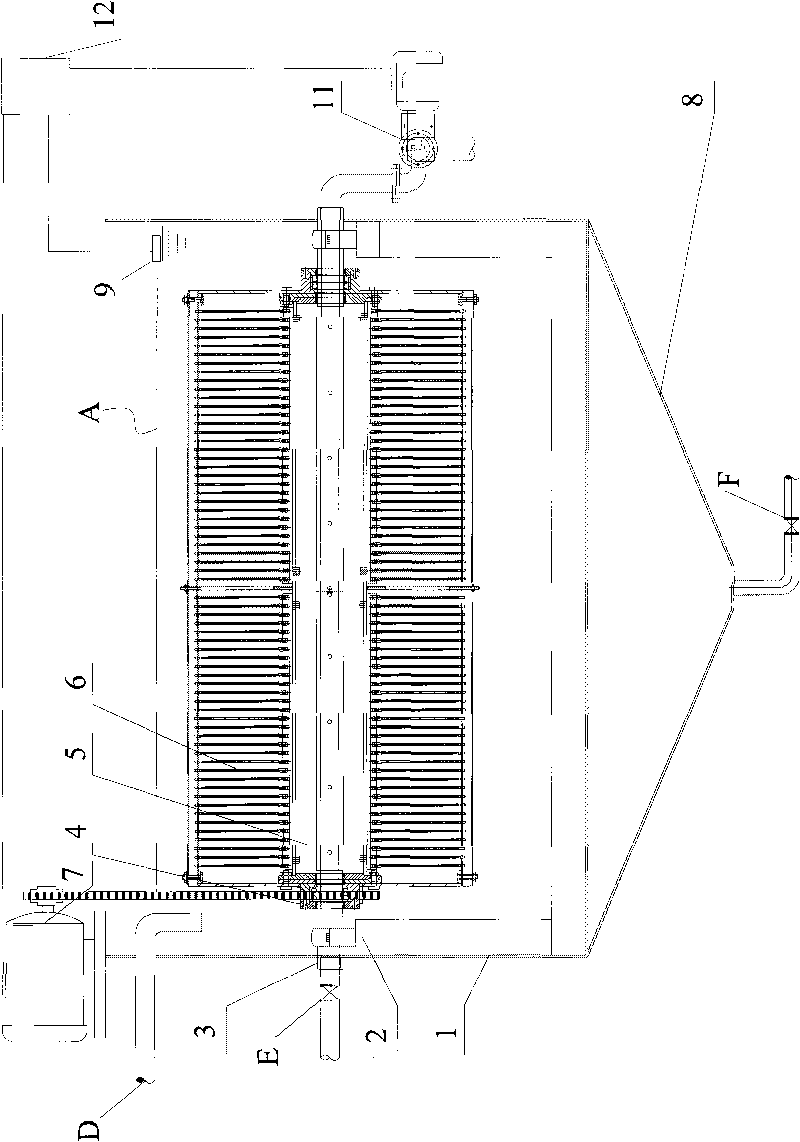

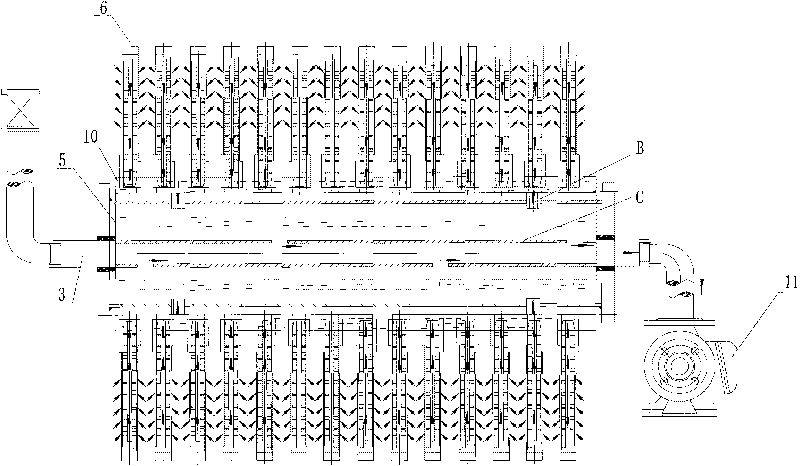

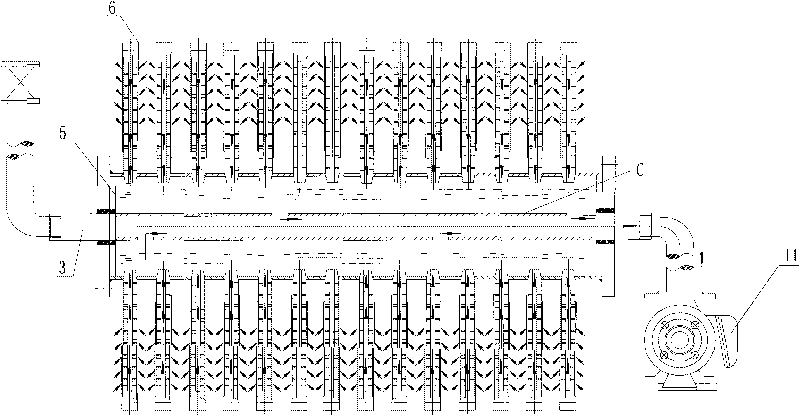

[0027] Such as figure 1 , figure 2 and image 3As shown, the rotary membrane separation device mainly includes a support 2, a hollow shaft 3, a drum 5, a filter membrane unit 6 and a motor 7, the two ends of the hollow shaft 3 are fixed on the support 2, and a hollow shaft 3 is sleeved Drum 5, there are sealing plates at the left and right ends of the drum 5, forming a circular cavity, and the left and right ends of the drum 5 are freely rotatably supported on the hollow shaft 3 through bearing bushes, so as to ensure that there is no leakage of liquid from the connection and the rotation of the drum. Free rotation; the hollow shaft 3 is provided with a communication hole C, and the cavity of the drum 5 communicates with the cavity of the hollow shaft 3 through the communication hole C; The junction of the manifold 10 and the drum 5 is provided with a communication port B, and the cavity of the manifold 10 communicates with the cavity of the drum 5 through the communication...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com