Treatment method and treatment system for percolate in garbage-burning plant

A waste incineration and treatment system technology, applied in the field of waste pollutant treatment, can solve problems such as affecting the effect of biochemical treatment, high concentrations of calcium and magnesium, and complicated process control, so as to avoid sludge loss, reduce the amount of concentrated liquid, and process control simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the protection scope of the present invention.

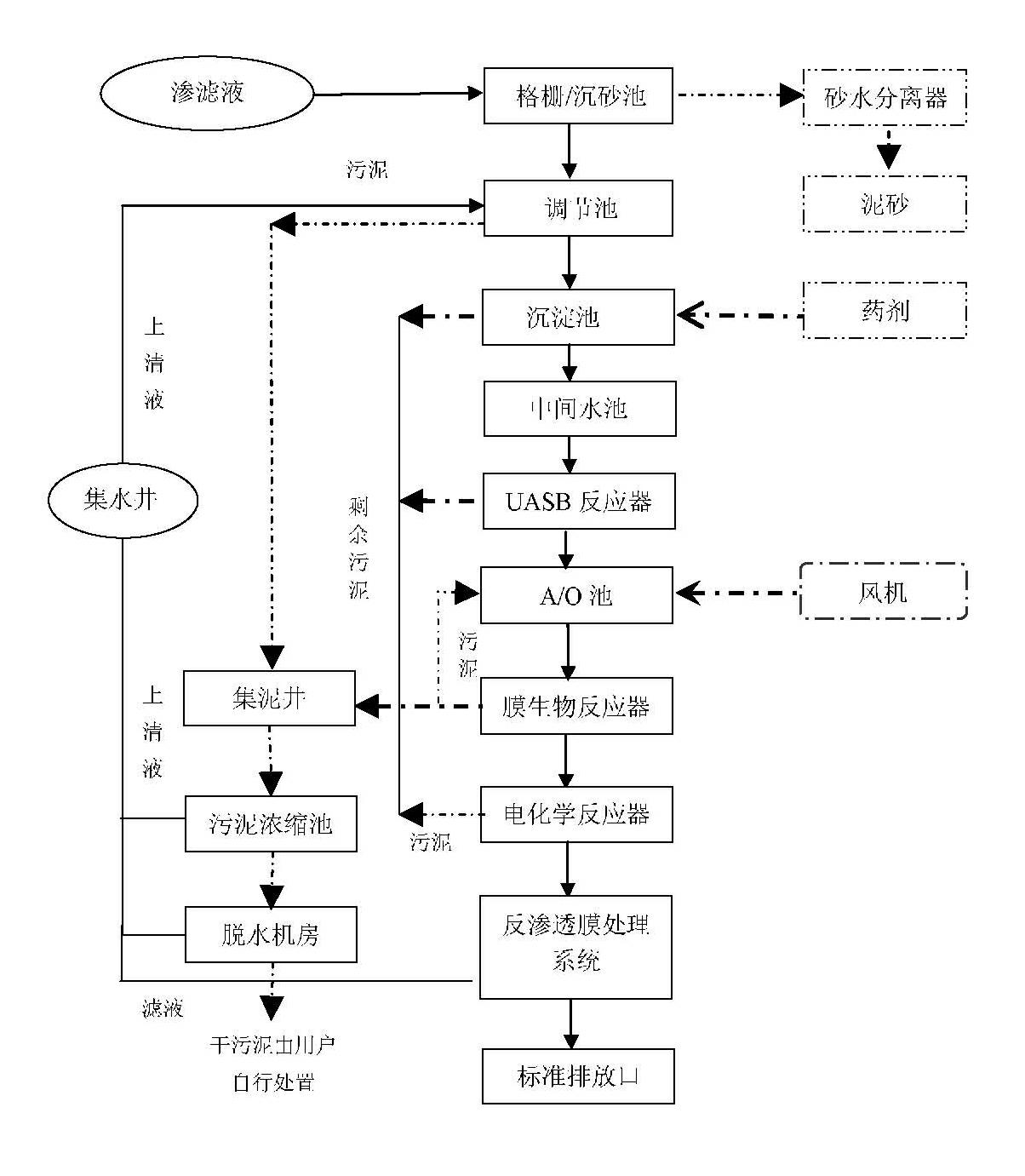

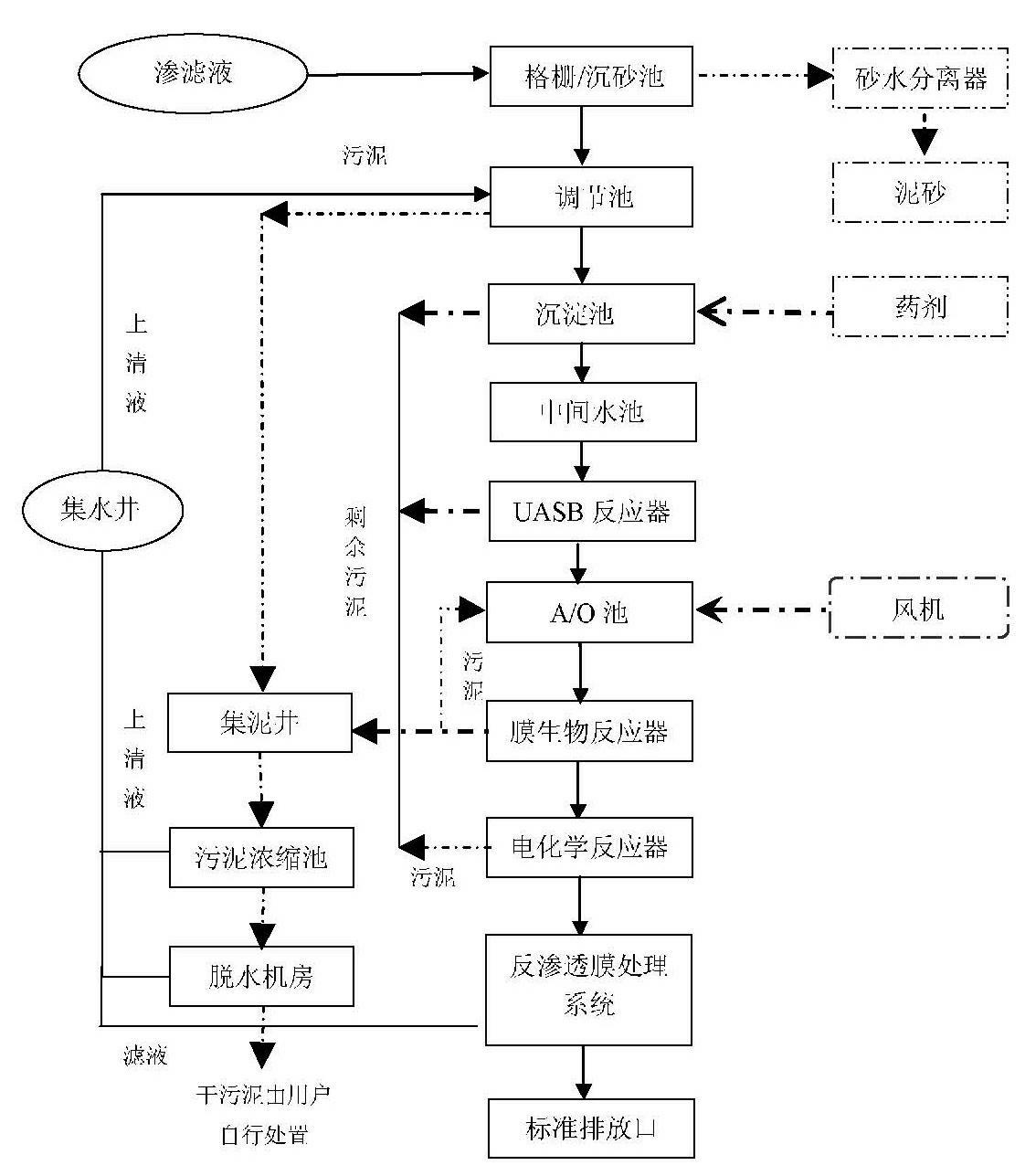

[0054] A method for treating leachate of a waste incineration plant, the steps of which are:

[0055] 1) After the leachate is collected by the pipeline, it enters the coarse and fine grids and the grit chamber, and then flows into the regulating tank for mixing after being gritted;

[0056]2) The effluent of the regulating tank is lifted to the sedimentation tank by the lifting pump of the regulating tank. By adjusting the pH value and adding an appropriate amount of coagulant, the effluent of the regulating tank is coagulated and precipitated to remove most of the suspended solids and part of the insoluble organic matter;

[0057] 3) Flow the effluent from the sedimentation tank into the intermediate pool and heat it to about 35°C through the steam jet he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com