Clothing pattern structure having high air permeability and prism effect

A gas-permeable, prism-based technology, applied in clothing, clothing, protective clothing, etc., to achieve the effect of simple printing process and low plate-making cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

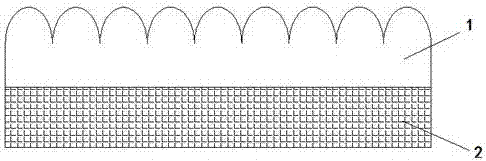

[0033] A clothing pattern structure with high air permeability and prism effect, characterized in that it includes a prism layer 1 and a breathable layer 2, the prism layer includes A surface and B surface, the A surface and the B surface are integrally connected, and the A surface Surface and surface B are in different horizontal planes.

[0034] Further, the included angle between the A surface and the B surface is 80°.

[0035] Further, the surface A is flat.

[0036] Further, the B surface is a plane with radians.

[0037] Further, the B surface is symmetrically arranged on both sides of the A surface.

[0038] A method for processing a garment pattern structure with high air permeability and prism effect, characterized in that it comprises the following steps:

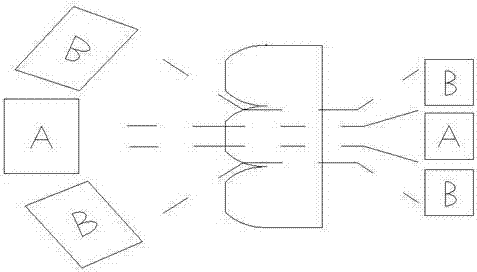

[0039] S1. Pretreatment: Align and place processed products, hot stamping glue, and non-woven fabrics to the hot stamping machine processing platform in sequence for hot stamping treatment;

[0040] S2. Silk s...

Embodiment 2

[0055] A clothing pattern structure with high air permeability and prism effect, characterized in that it includes a prism layer 1 and a breathable layer 2, the prism layer includes A surface and B surface, the A surface and the B surface are integrally connected, and the A surface Surface and surface B are in different horizontal planes.

[0056] Further, the included angle between the A surface and the B surface is 75°.

[0057] Further, the surface A is a horizontal surface with a radian.

[0058] Further, the B surface is a plane with radians.

[0059] Further, the B surface is symmetrically arranged on both sides of the A surface.

[0060] A method for processing a garment pattern structure with high air permeability and prism effect, characterized in that it comprises the following steps:

[0061] S1. Pretreatment: Align and place processed products, hot stamping glue, and non-woven fabrics to the hot stamping machine processing platform in sequence for hot stamping t...

Embodiment 3

[0070] A clothing pattern structure with high air permeability and prism effect, characterized in that it includes a prism layer 1 and a breathable layer 2, the prism layer includes A surface and B surface, the A surface and the B surface are integrally connected, and the A surface Surface and surface B are in different horizontal planes.

[0071] Further, the included angle between the A surface and the B surface is 85°.

[0072] Further, the surface A is a horizontal surface with a radian.

[0073] Further, the B surface is a plane with radians.

[0074] Further, the B surface is symmetrically arranged on both sides of the A surface.

[0075] A method for processing a garment pattern structure with high air permeability and prism effect, characterized in that it comprises the following steps:

[0076] S1. Pretreatment: Align and place processed products, hot stamping glue, and non-woven fabrics to the hot stamping machine processing platform in sequence for hot stamping t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com