Sealing cover balance filling packaging structure and process for sorted flip chips

A technology of flip-chip and packaging structure, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., and can solve problems such as inability to meet individual requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described below in conjunction with accompanying drawing.

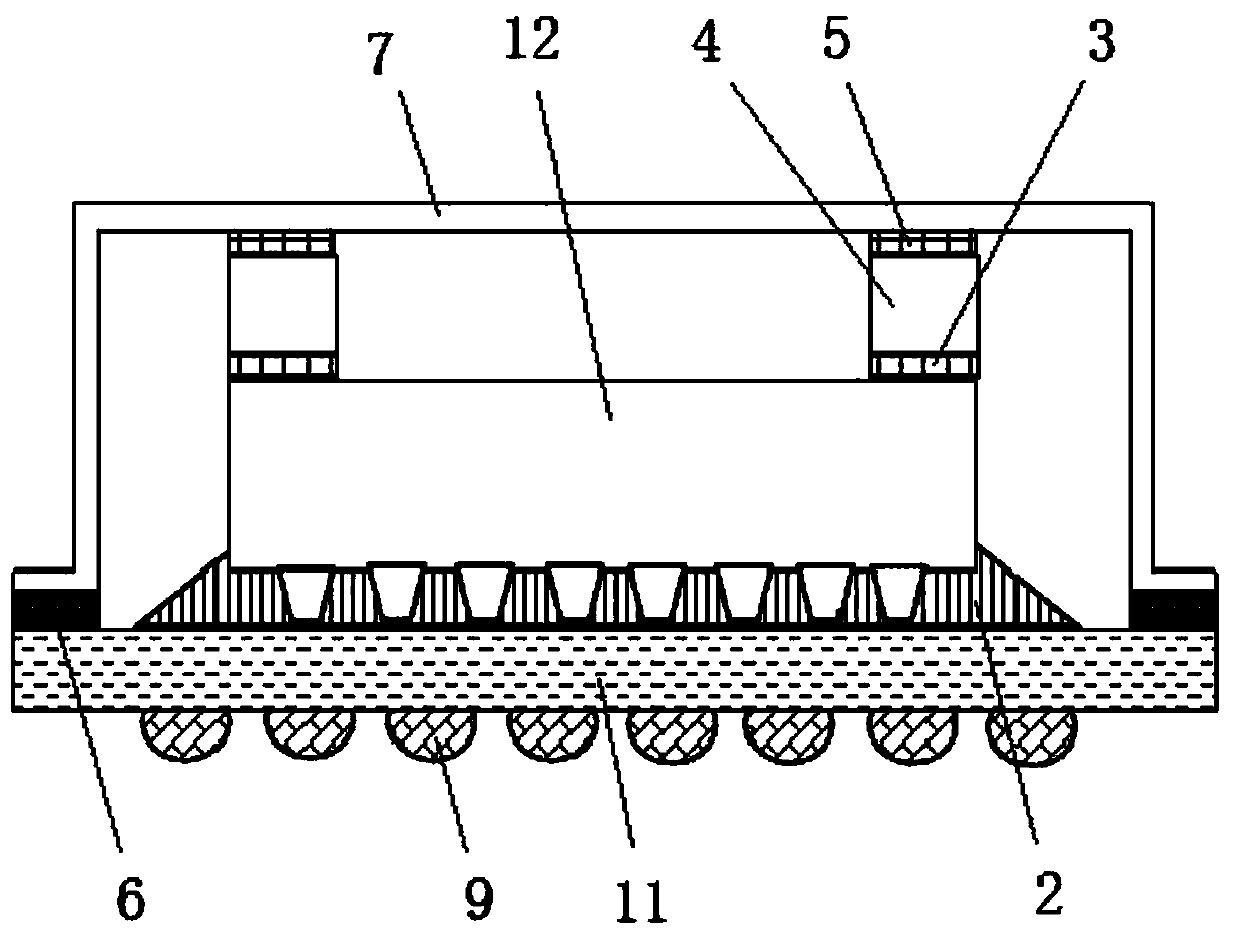

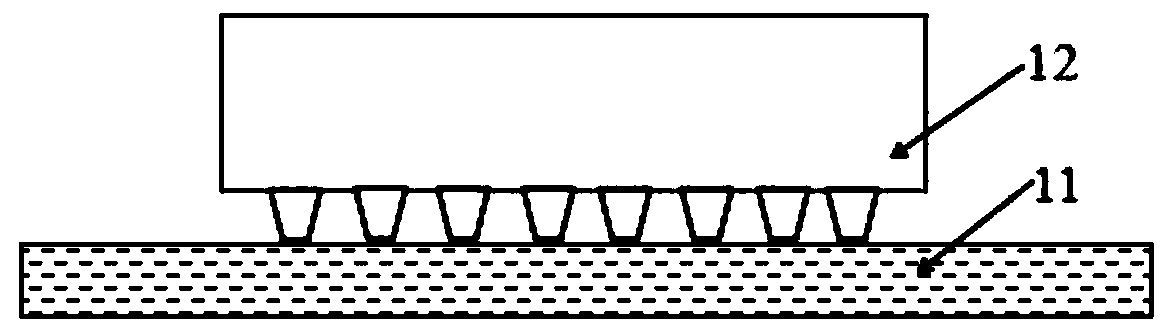

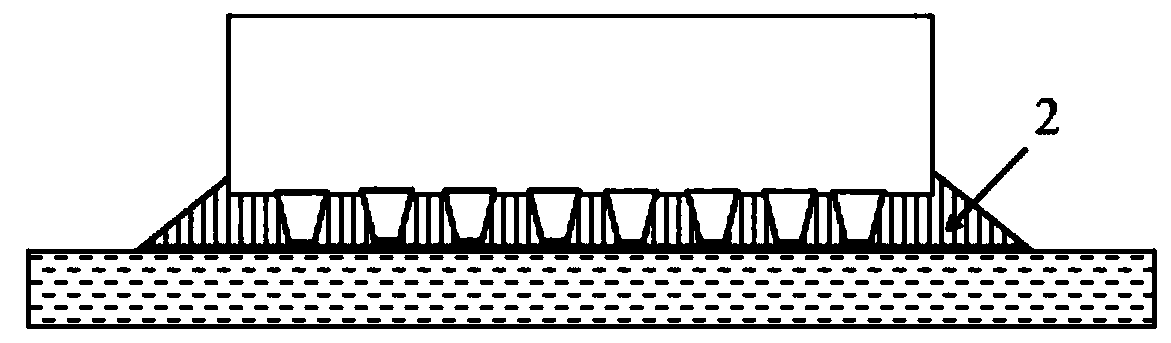

[0044] as attached figure 1 As shown in the present invention, a cover balance filling package structure for sorting flip chips includes a substrate 11, a flip chip 12 and a metal cover 7, the bottom of the substrate 11 is soldered with solder balls 9, and the metal cover 7 The frame of the frame is welded on the substrate 11 through solder 6, and the flip chip 12 is located in the metal cover 7; the front side of the flip chip 12 has a plurality of bumps, and the filling glue 2 is arranged between the flip chip 12 and the substrate 11, Filler 2 fills the gap between the flip chip 12 and the substrate 11, and the gap between the bumps; the left and right sides of the back of the flip chip 12 are provided with silicon pads 4, silicon pads 4 Paste on the back of the flip chip 12 through the lower heat-conducting adhesive layer 3 on its lower side, the upper side of the silicon gasket 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com