Preparation method of nano silver solution and polyaniline/ silver nanocomposite

A technology of nano-silver sol and composite materials, which is applied in the field of preparation of nano-silver sol and polyaniline/silver nano-composite materials, achieving the effects of less equipment, low overall cost and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

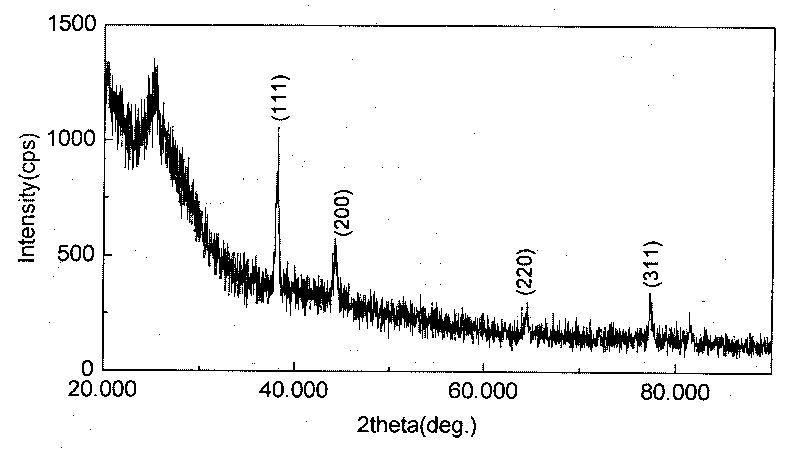

[0041] The present invention at first provides a kind of preparation method of nano-silver sol, and concrete steps are as follows:

[0042] Step 1, according to the molar ratio of linear alkylbenzene sulfonic acid, aniline, silver nitrate is: (6~10): 2: (4~5) prepare raw material, first take 4 / 5 of required deionized water amount, add For linear alkylbenzene sulfonic acid, stir for fifteen minutes to dissolve and disperse evenly;

[0043] Add aniline to the above solution, and continue stirring rapidly for half an hour to make the solution clear;

[0044] Dissolve silver nitrate in one-fifth of the required amount of deionized water, add it to the aforementioned solution, and continue stirring for half an hour until the mixture is evenly distributed.

[0045] The concentration of silver nitrate in the mixed solution is 0.01-0.1mol / L.

[0046] Step 2. Add dropwise 1 mol / L sodium hydroxide solution to the mixed solution prepared in step 1 until it completely turns yellowish br...

Embodiment 1

[0062] Nano silver sol preparation:

[0063] At room temperature, add 1.630g of dodecylbenzenesulfonic acid (0.005mol) to 40mL of deionized water, stir for fifteen minutes to dissolve it completely; then add 0.093g of aniline (0.001mol) to it, and stir for half an hour until the solution becomes clarify. Add 0.425g of silver nitrate (0.0025mol) to 10mL of deionized water, stir to dissolve it and pour it into the former, and continue to stir for half an hour.

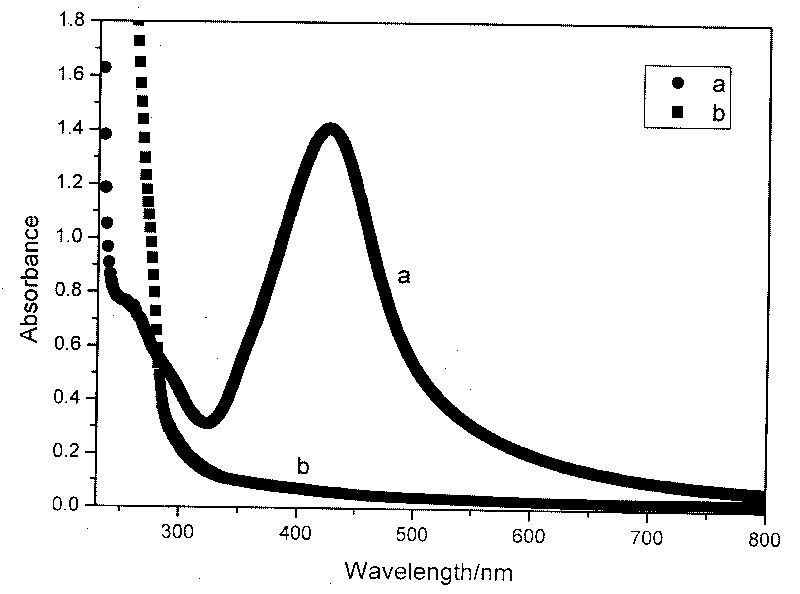

[0064] Slowly add 1mol / L NaOH solution dropwise to the above 50mL mixed solution until the reaction solution completely turns yellow-brown turbid; continue to stir at room temperature for 48 hours to obtain nano-silver hydrosol.

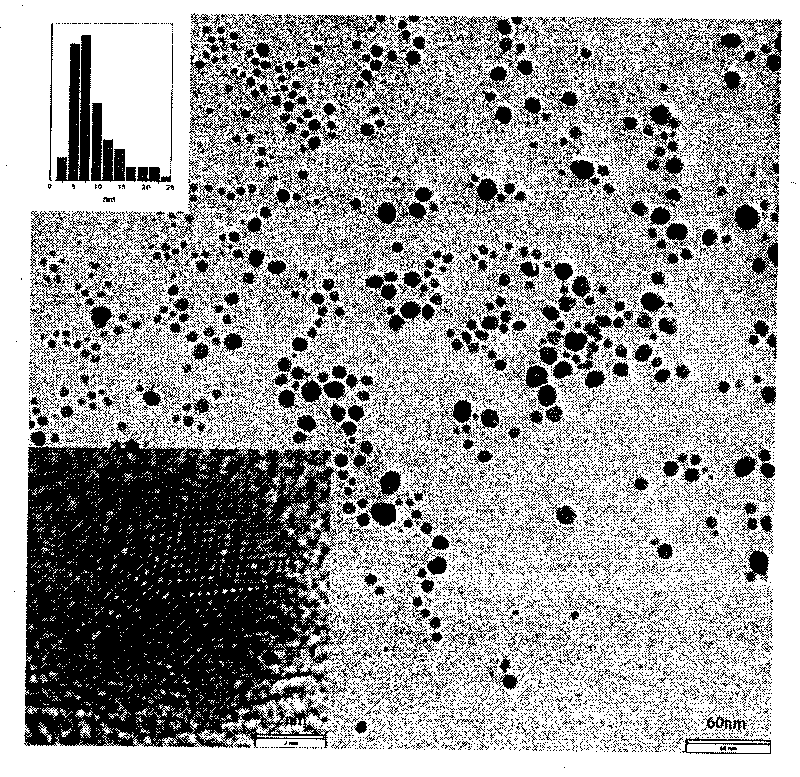

[0065] The obtained nano-silver hydrosol is placed statically and can be used for the preparation of polyaniline / silver nano-composite materials at any time; if relatively pure nano-silver powder or sol is needed, then take the obtained nano-silver hydrosol in a centrifuge tube and centrifuge ...

Embodiment 2

[0070] At room temperature, add 1.956g of dodecylbenzenesulfonic acid (0.006mol) to 40mL of deionized water, stir for fifteen minutes to dissolve completely; then add 0.850g of aniline (0.002mol) to it, and stir for half an hour until the solution becomes clarify. Add 0.425g of silver nitrate (0.005mol) to 10mL of deionized water, stir to dissolve it, pour it into the former, and continue to stir for half an hour.

[0071] Slowly add 1mol / L NaOH solution dropwise to the above 50mL reaction solution until the reaction solution completely turns yellowish brown and turbid; continue to stir at room temperature for 24 hours to react to obtain nano-silver hydrosol.

[0072] The obtained nano-silver hydrosol is placed statically and can be used for the preparation of polyaniline / silver nano-composite materials at any time; if a relatively pure nano-silver sol or powder is needed, then take the obtained nano-silver hydrosol in a centrifuge tube and centrifuge at 12000rpm for 20 ~30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com