Energy-saving and environment-friendly aluminum alloy anode oxide film stripping process

An anodic oxidation film, energy-saving and environmental protection technology, applied in the field of metal surface treatment, can solve the problems of high temperature, insufficient precision of film withdrawal, environmental hazards, etc., and achieve the effect of ensuring the use requirements, high precision of film withdrawal, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Adopt proportioning ratio to be sulfuric acid 15g L -1 , oxalic acid 25g L -1 , corrosion inhibitor 20g L -1 , wherein the composition of the corrosion inhibitor is: adipate 15g L -1 , molybdate 30g L -1 . The anodized aluminum alloy samples were subjected to film removal treatment.

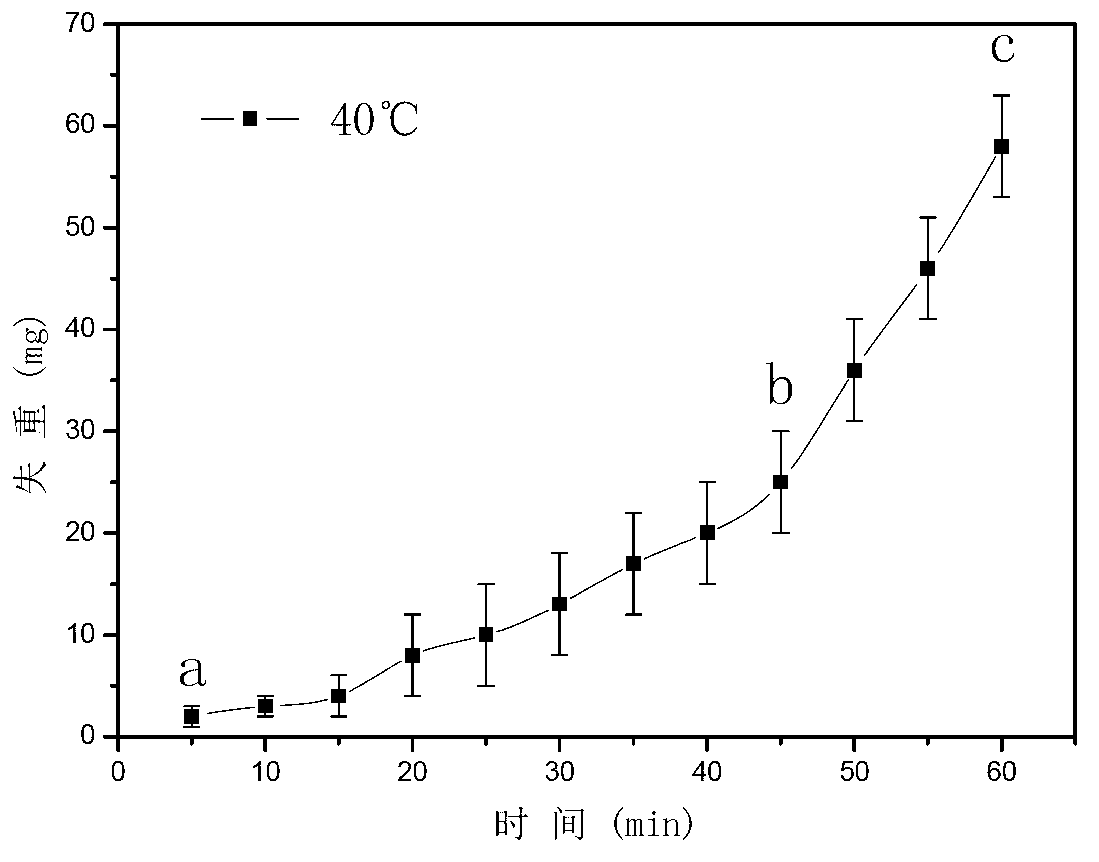

[0024] The 2A12 aluminum alloy with a sample size of 100×50×2mm was soaked in a film-removing solution at 40°C after traditional sulfuric acid anodization and boiling water sealing treatment. The film withdrawal time is 5-60 minutes, and the weight loss test is carried out every 5 minutes during this period. Five parallel samples were selected for each test point, and the average value was taken for the weight loss of the film.

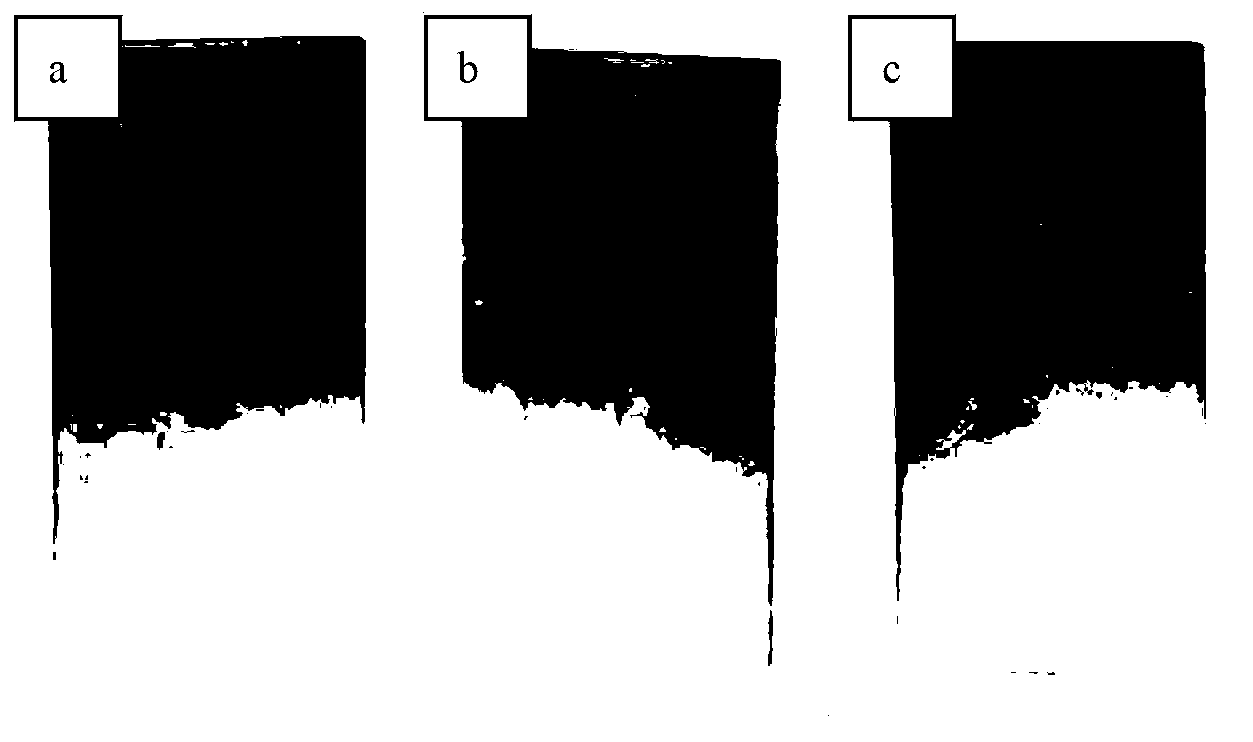

[0025] figure 1 It is the curve of film weight loss over time. From the figure, it can be seen that the film layer removal under this process is roughly divided into two stages: Ⅰ. From the beginning point a to point b, the rising slope of weight loss in th...

Embodiment 2

[0028] Adopt proportioning ratio to be sulfuric acid 20g L -1 , oxalic acid 30g L -1 , corrosion inhibitor 30g L -1 , wherein the composition of the corrosion inhibitor is: adipate 10g L -1 , molybdate 25g L -1 . The anodized aluminum alloy samples were subjected to film removal treatment.

[0029] The 2A12 aluminum alloy with a sample size of 100 × 50 × 2 mm was immersed in a film-removing solution at 30 ° C after traditional sulfuric acid anodic oxidation and sealing treatment. The film withdrawal time is 5-60 minutes, and the weight loss test is carried out every 5 minutes during this period. Five parallel samples were selected for each test point, and the average value was taken for the weight loss of the film.

[0030] The weight loss-time curve of this process is divided into two stages: the film layer removal stage and the substrate corrosion stage. From the beginning of the film removal to the substrate corrosion stage after the film removal, the surface of the s...

Embodiment 3

[0032] Adopt proportioning ratio to be sulfuric acid 15g L -1 , oxalic acid 35g L -1 , corrosion inhibitor 30g L -1 , wherein the composition of the corrosion inhibitor is: adipate 15g L -1 , molybdate 25g L -1 . The anodized aluminum alloy samples were subjected to film removal treatment.

[0033] The 2A12 aluminum alloy with a sample size of 100×50×2mm was immersed in a film-removing solution at 35°C after traditional sulfuric acid anodization and sealing treatment. The film withdrawal time is 5-60 minutes, and the weight loss test is carried out every 5 minutes during this period. Five parallel samples were selected for each test point, and the average value was taken for the weight loss of the film.

[0034] The weight loss-time curve of this process is divided into two stages: the film layer removal stage and the substrate corrosion stage. From the beginning of the film removal to the substrate corrosion stage after the film removal, the surface of the sample is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com