Superlong vanadium dioxide nanowire film and preparation method thereof

A technology of vanadium dioxide nanometer and vanadium pentoxide, which is applied in the field of template-free ultra-long vanadium dioxide nanowire film and its preparation, can solve the problems of high production equipment requirements, high temperature, large energy consumption, etc. Chemical properties, large specific surface area, the effect of reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

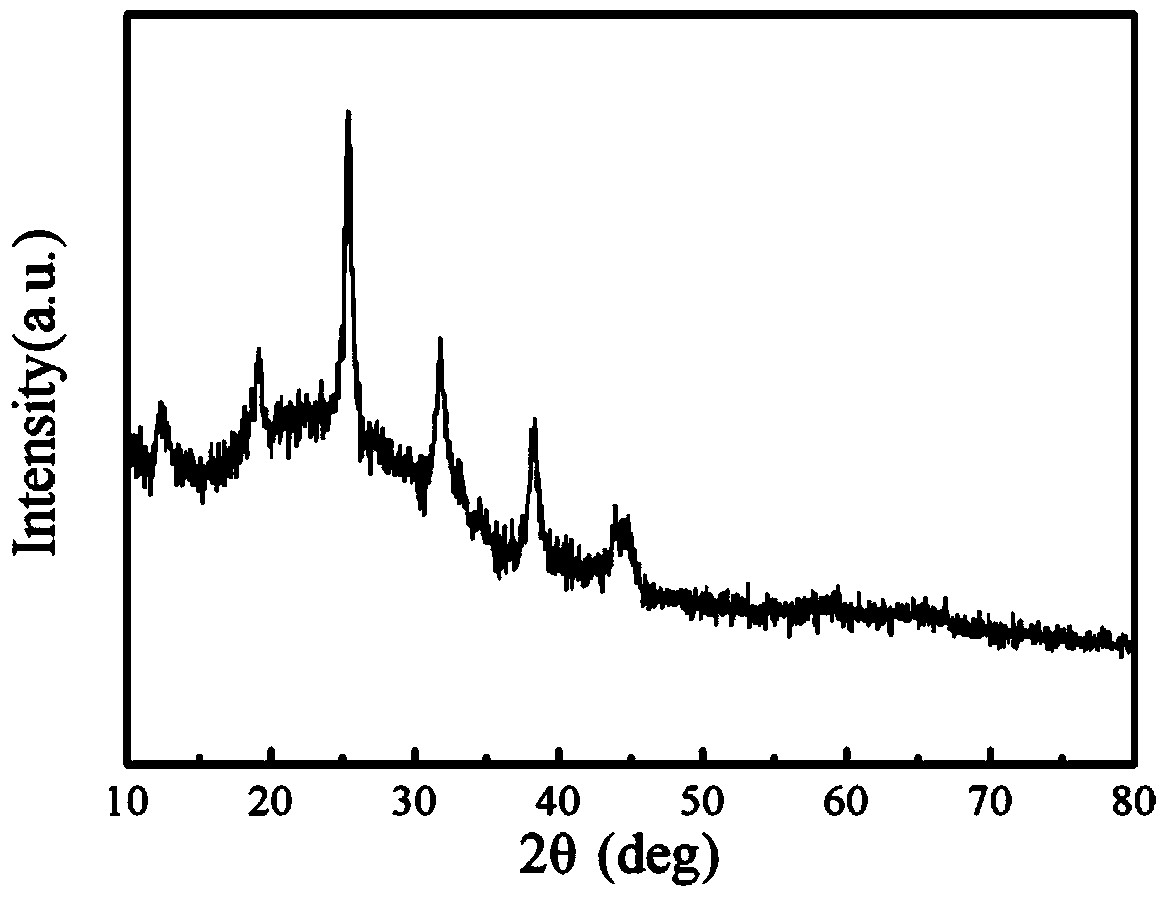

[0032] A method for preparing a template-free vanadium dioxide ultra-long nanowire film. First weigh 0.05-0.5g of vanadium pentoxide, put it into a beaker, add 40ml of double distilled water into the beaker, stir vigorously, then take 0.1-3ml of hydrogen peroxide into the beaker, stir for 0.1-1h, and form an orange-red transparent solution , then add an oxalic acid solution with a mass volume concentration of 1.25-12.5g / L to the solution, stir for 5min-1h, then place the mixed solution evenly in a 60ml polytetrafluoroethylene lining, and the hydrothermal temperature is 80-120°C, The holding time is 96h, cooled naturally, the sample is washed with distilled water and ethanol, and dried at 60°C for 12h to obtain a vanadium dioxide ultra-long nanowire film. figure 1 For the XRD pattern of the sample tested, it can be known by analyzing and comparing the cards that the vanadium dioxide is B-phase vanadium dioxide, which is consistent with the card JCPDS Card No.81-2392. By consult...

Embodiment 2

[0034]A method for preparing a template-free vanadium dioxide ultra-long nanowire film. First weigh 0.05-0.5g of vanadium pentoxide, put it into a beaker, add 40ml of double distilled water into the beaker, stir vigorously, then take 0.1-3ml of hydrogen peroxide into the beaker, stir for 0.1-1h, and form an orange-red transparent solution , then add an oxalic acid solution with a mass volume concentration of 1.25-12.5g / L to the solution, stir for 5min-1h, then place the mixed solution in a 60ml polytetrafluoroethylene lining, heat the water at 120-180°C, and keep warm After 24 hours, cool naturally, wash the sample with distilled water and ethanol, and dry at 60° C. for 12 hours to obtain a vanadium dioxide ultralong nanowire film. image 3 , Figure 4 It is a scanning electron microscope picture of the sample. According to the picture, we can see that the vanadium dioxide nanowire has a diameter of 50-200nm and a length of 50μm-1cm.

Embodiment 3

[0036] A method for preparing a template-free vanadium dioxide ultra-long nanowire film. First weigh 0.5-3g of vanadium pentoxide, put it into a beaker, add 40ml of double distilled water into the beaker, stir vigorously, then take 3-6ml of hydrogen peroxide into the beaker, stir for 1-5h, and form an orange-red transparent solution. Then add oxalic acid solution with a mass volume concentration of 1.25-12.5g / L to the solution, stir for 5min-1h, then place the mixed solution in a 60ml polytetrafluoroethylene lining, the water heating time is 120-180°C, and the holding time After 48 hours, cool naturally, wash the sample with distilled water and ethanol, and dry at 60°C for 12 hours to obtain a vanadium dioxide ultralong nanowire film. The vanadium dioxide nanowire has a diameter of 50-300nm and a length of 50μm-2cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com