Modified polyester and preparation method thereof

A modified polyester and copolymerization technology, which is applied in the field of modified polyester and its preparation, can solve the problems of high brittleness, easy fracture, and low yield of PET film, and achieve the goal of reducing brittleness, reducing cost, and increasing yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

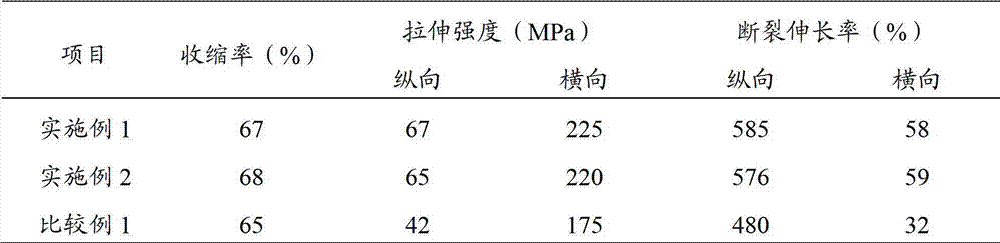

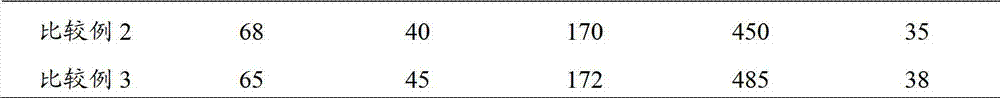

Examples

preparation example Construction

[0022] The present invention also provides a kind of preparation method of modified polyester, comprises the following steps:

[0023] Mix isophthalic acid, neopentyl glycol, 1,4-cyclohexanedimethanol, terephthalic acid and ethylene glycol, and carry out esterification reaction at 240°C~280°C to obtain esterified products;

[0024] The temperature of the esterification product is raised to 250° C. to 290° C. to carry out polycondensation reaction to obtain a modified polyester.

[0025] The invention uses terephthalic acid and ethylene glycol as raw materials and isophthalic acid, neopentyl glycol and 1,4-cyclohexanedimethanol as modifiers to prepare modified polyester. In the present invention, firstly, isophthalic acid, neopentyl glycol, 1,4-cyclohexanedimethanol, terephthalic acid and ethylene glycol are mixed, and the esterification reaction is carried out at 240°C to 280°C. In the present invention, after heating the esterification tank to 240°C, add isophthalic acid, ne...

Embodiment 1

[0039] Add 91.2g of terephthalic acid, 8.8g of isophthalic acid, 87.14g of ethylene glycol, 9.6g of neopentyl glycol and 3.26g of 1,4-cyclohexanedimethanol into the slurry configurer, stir well to obtain a reaction mixture ; After raising the temperature of the esterification reaction kettle to 250°C, add the above-mentioned reaction mixture into it, raise the temperature and start stirring, control the temperature of the kettle between 240°C and 280°C, add the blueness agent, and slowly release the generated esterification reaction product; Add the above esterification reaction product into the polycondensation kettle, raise the temperature to 260°C and start slowly vacuuming, and finally carry out the high-vacuum polycondensation reaction between 250°C and 290°C, and stir the polycondensation reaction at the same time. The stirring process is as follows: first, at 50HZ, Stir under the condition of 0.6kW. When it reaches 2.1kW, reduce it to 35HZ and continue stirring. When it ...

Embodiment 2

[0044] Add 87g of terephthalic acid, 13g of isophthalic acid, 85g of ethylene glycol, 5g of neopentyl glycol and 10g of 1,4-cyclohexanedimethanol into the slurry configurer, and stir evenly to obtain a reaction mixture; After the temperature of the kettle is raised to 250°C, add the above-mentioned reaction mixture into it, raise the temperature and start stirring, control the temperature of the kettle between 240°C and 280°C, add the blueness agent, and slowly release the generated esterification reaction product; the esterification reaction product Add it into the polycondensation kettle, raise the temperature to 260°C and start to vacuumize slowly, and finally carry out high-vacuum polycondensation reaction between 250°C and 290°C, and stir while polycondensation reaction. The stirring process is as follows: first, under the conditions of 50HZ and 0.6kW Stir, when it reaches 2.1kW, reduce to 35HZ and continue stirring, when it reaches 2.0KW, reduce to 25HZ, when the stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com