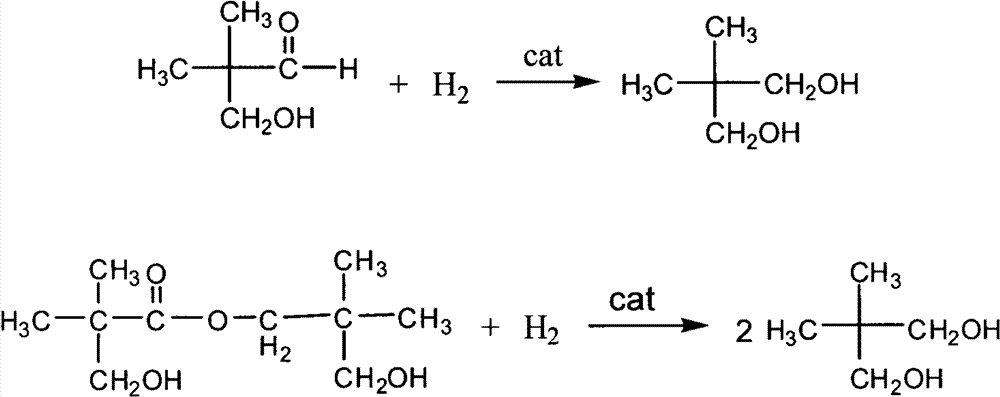

Catalyst for preparing neopentyl glycol by hydrogenation and preparation method of catalyst

A technology for neopentyl glycol and catalyst, which is applied to the catalyst for hydrogenation to prepare neopentyl glycol and the field of preparation thereof, can solve the problems of low conversion rate, high HPA decomposition rate, poor selectivity, etc., and achieves reduction of decomposition and simplification of post-processing. , the effect of reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

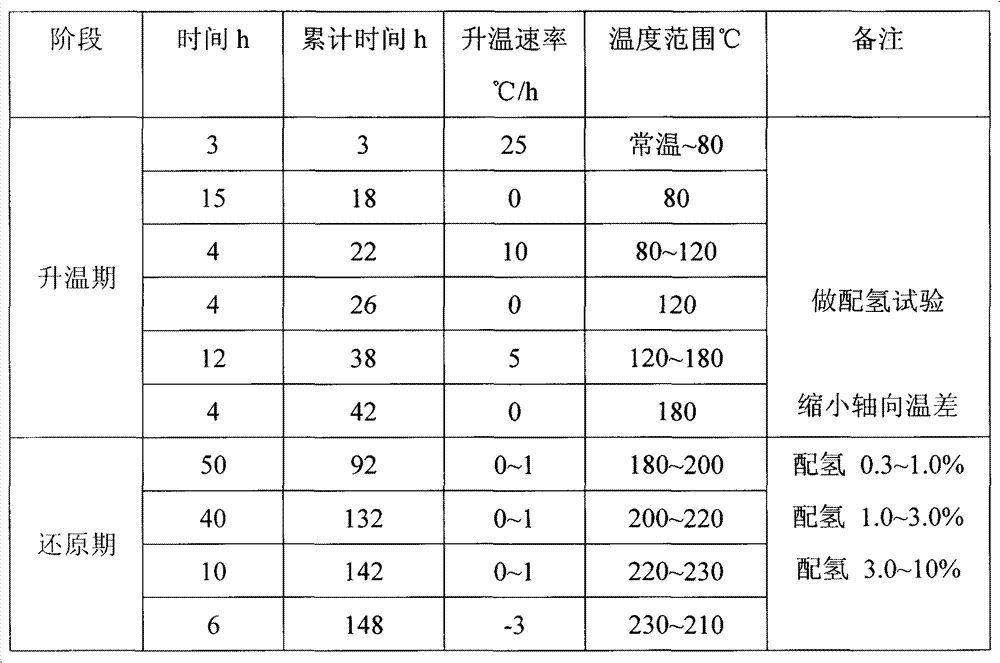

Method used

Image

Examples

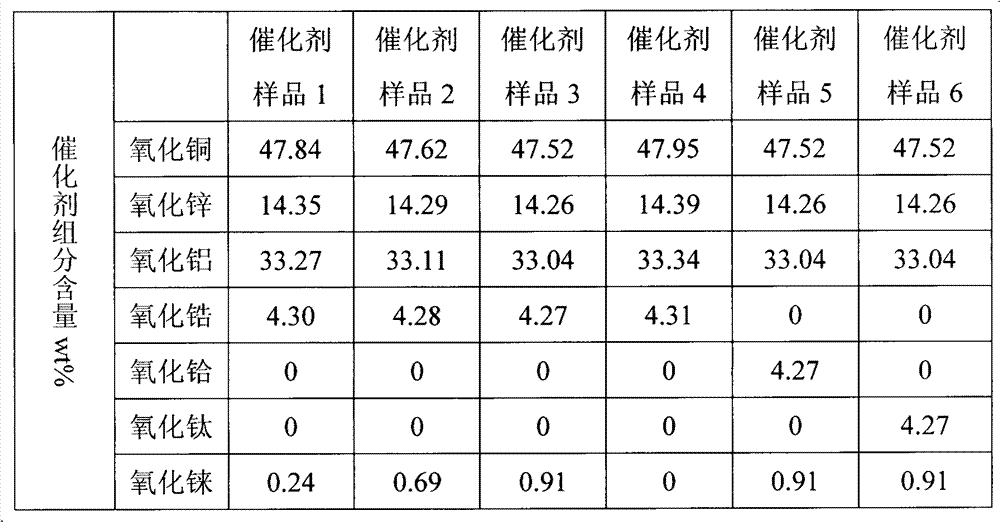

Embodiment 1

[0037] 12.6g zirconium nitrate, 120g copper nitrate, 35.55g zinc nitrate, 147.88g aluminum nitrate, 0.65g rhenium nitrate were dissolved in water to prepare 1000ml, and 25wt% sodium carbonate aqueous solution was slowly added dropwise to the tank with stirring and heating and heat preservation functions. In the reaction kettle, control the reaction temperature at 85-90°C, the reaction process requires a pH between 9.5-10.5, keep the reaction at 1-1.5 hours, cool down to 65°C and age for 1.5 hours, then perform centrifugation, and deionize the solid phase Wash with water until the sodium content is less than 0.1%, dry at 700°C for 1.5 hours after solid-phase drying, and press into pellets to prepare the catalyst sample 1.

Embodiment 2

[0039] The amount of other nitrates was as in Example 1, and the amount of rhenium nitrate was increased to 1.9 g, and the preparation method was as in Example 1 to prepare catalyst sample 2.

Embodiment 3

[0041] The amount of other nitrates was as in Example 1, and the amount of rhenium nitrate was increased to 2.5 g, and the preparation method was as in Example 1 to prepare catalyst sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com