Artificial solid plane materiel and manufacturing method thereof

A solid and surface material technology, applied in the field of artificial solid surface materials and its manufacturing, can solve problems such as fragile, easy to deform, easy to scratch, etc., and achieve the effect of improving surface hardness, improving water resistance, and not easily deforming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

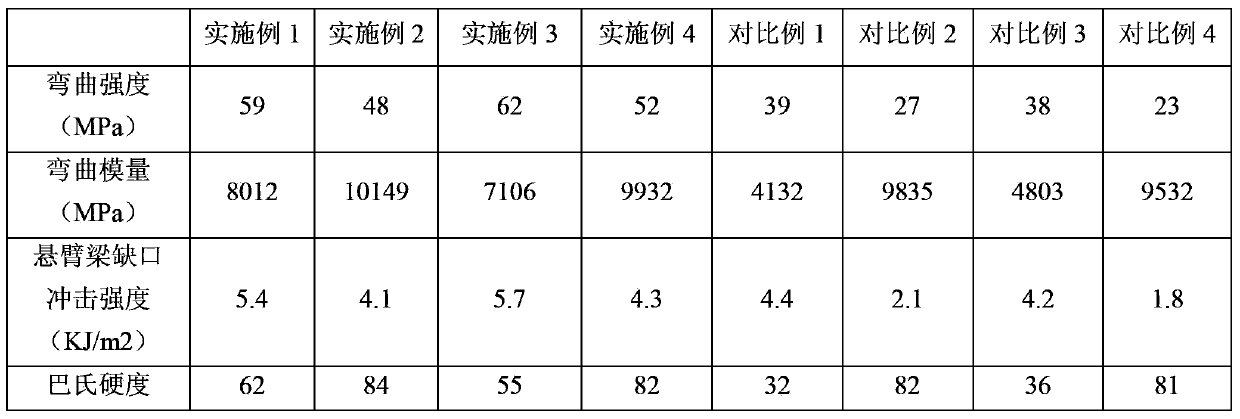

Examples

Embodiment 1

[0055] 5kg of unsaturated polyester resin with a viscosity of 300cps (wherein, when the unsaturated polyester resin was prepared, neopentyl glycol was 20wt%, and maleic anhydride was 10wt%);

[0056] 50wt% titanium dioxide color paste 1kg;

[0057] 40 mesh quartz powder 25kg;

[0058] 100 mesh glass powder 25kg;

[0059] 200 mesh feldspar powder 32kg;

[0060] 300 mesh aluminum hydroxide 10kg;

[0061] 80nm modified quartz powder 3kg;

[0062] Cobalt isooctanoate 0.01 kg; and

[0063] Potassium isooctanoate 0.01kg.

[0064] After the above components are stirred and mixed, add 0.1 kg of methyl ethyl ketone peroxide, mix evenly, put the mold into the mold, evacuate and vibrate to make the material level, about 35 minutes, break the vacuum and place it at room temperature, and solidify into a plate after 4 hours, and then put the plate Put it in an oven and bake at 100°C for 120 minutes, take it out to cool, and polish it to obtain light white artificial solid surface materi...

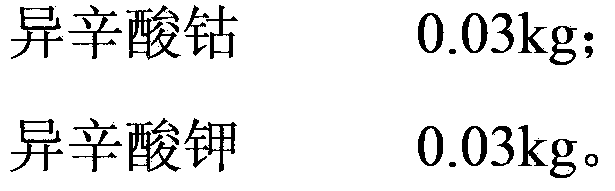

Embodiment 2

[0067] 20kg of unsaturated polyester resin with a viscosity of 700cps (wherein, when the unsaturated polyester resin is prepared, neopentyl glycol is 40wt%, and maleic anhydride is 35wt%);

[0068] 0.1kg of 50wt% titanium dioxide color paste;

[0069] 200 mesh alumina 46.43kg;

[0070] 200 mesh feldspar powder 30kg;

[0071] 300 mesh kaolin 1.57kg;

[0072] 300 mesh aluminum hydroxide 2kg;

[0073] Cobalt isooctanoate 0.03kg;

[0074] Potassium isooctanoate 0.03kg.

[0075] After stirring and mixing, add 0.3 kg of methyl ethyl ketone peroxide, mix evenly, put the mold into the mold, vacuum and vibrate to make the material level, about 8 minutes, break the vacuum and place it at room temperature, solidify into a plate after 4 hours, and then put the plate in the oven Bake at 100°C for 120 minutes, take it out to cool, and polish it to obtain light white artificial solid surface material Q2.

[0076] The obtained light white artificial solid surface material Q2 was tested ...

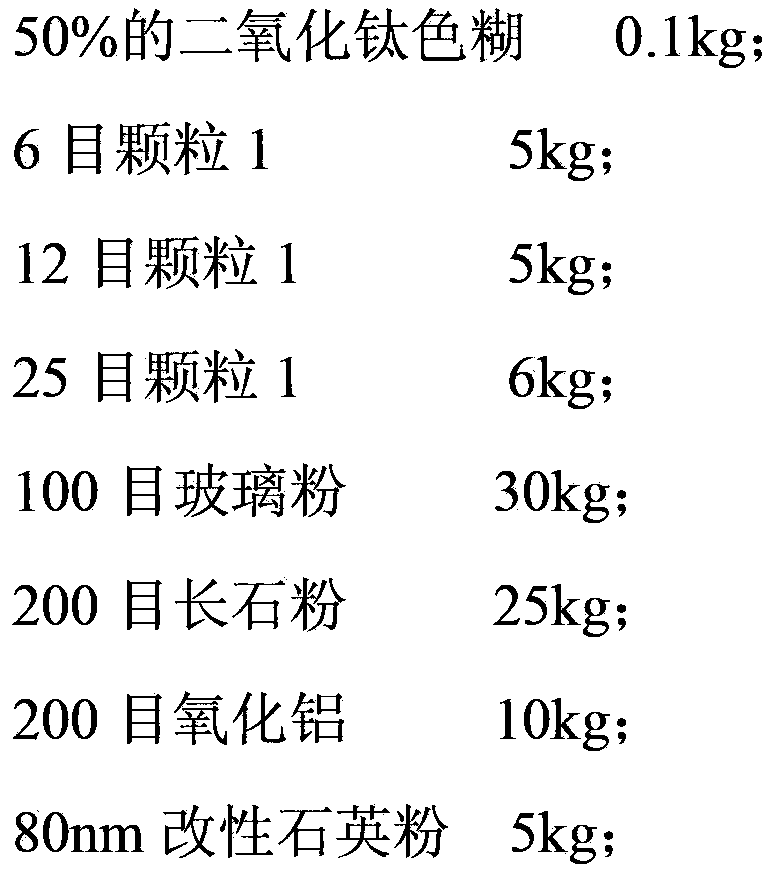

Embodiment 3

[0078] 45kg of unsaturated polyester resin with a viscosity of 1250cps (wherein, when the unsaturated polyester resin was prepared, neopentyl glycol was 40wt%, and maleic anhydride was 20wt%);

[0079] 0.1kg of 30wt% iron red paste;

[0080] 100 mesh glass powder 10kg;

[0081] 200 mesh talcum powder 12.4kg;

[0082] 300 mesh kaolin 12kg;

[0083] 80nm modified quartz powder 20.6kg;

[0084] Cobalt isooctanoate 0.04kg;

[0085] Potassium isooctanoate 0.04kg.

[0086] After stirring and mixing, add 0.4 kg of methyl ethyl ketone peroxide, mix evenly, put the mold into the mold and evacuate and vibrate to make the material level, about 10 minutes, break the vacuum and place it at room temperature. After 4 hours, it will solidify into a plate, and then put the plate in the oven Bake at 100°C for 120 minutes, take it out to cool, and polish it to obtain the red artificial solid surface material Q3.

[0087] The obtained red artificial solid surface material Q3 was tested for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com