Triazine ring combustion inhibitor containing phosphorus and its preparing process

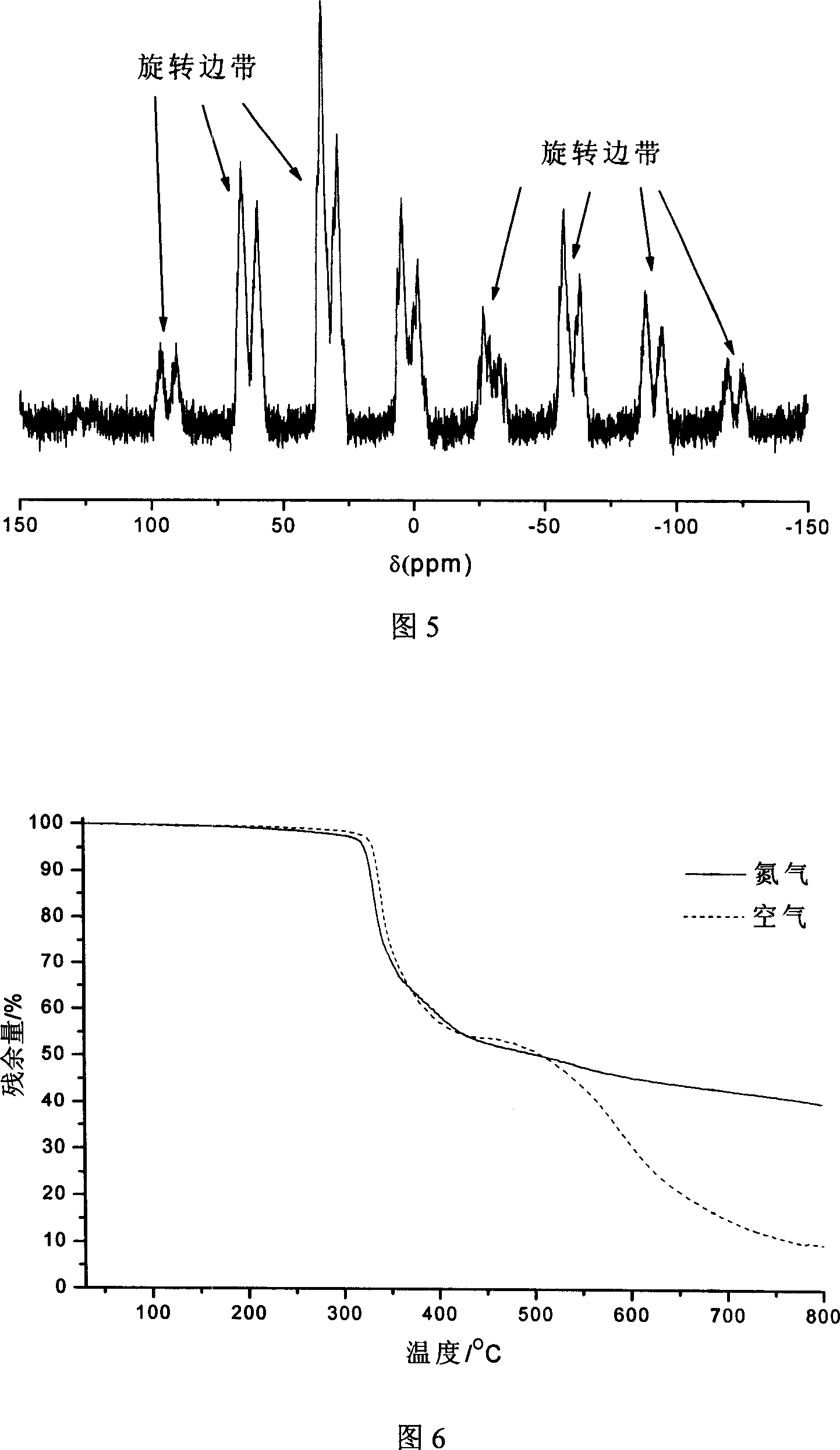

A technology of triazine ring and flame retardant, which is applied in the field of flame retardants, can solve the problems of easy decomposition, limited application, and low thermal stability of compounds, and achieves the effect of increasing the decomposition temperature and improving thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

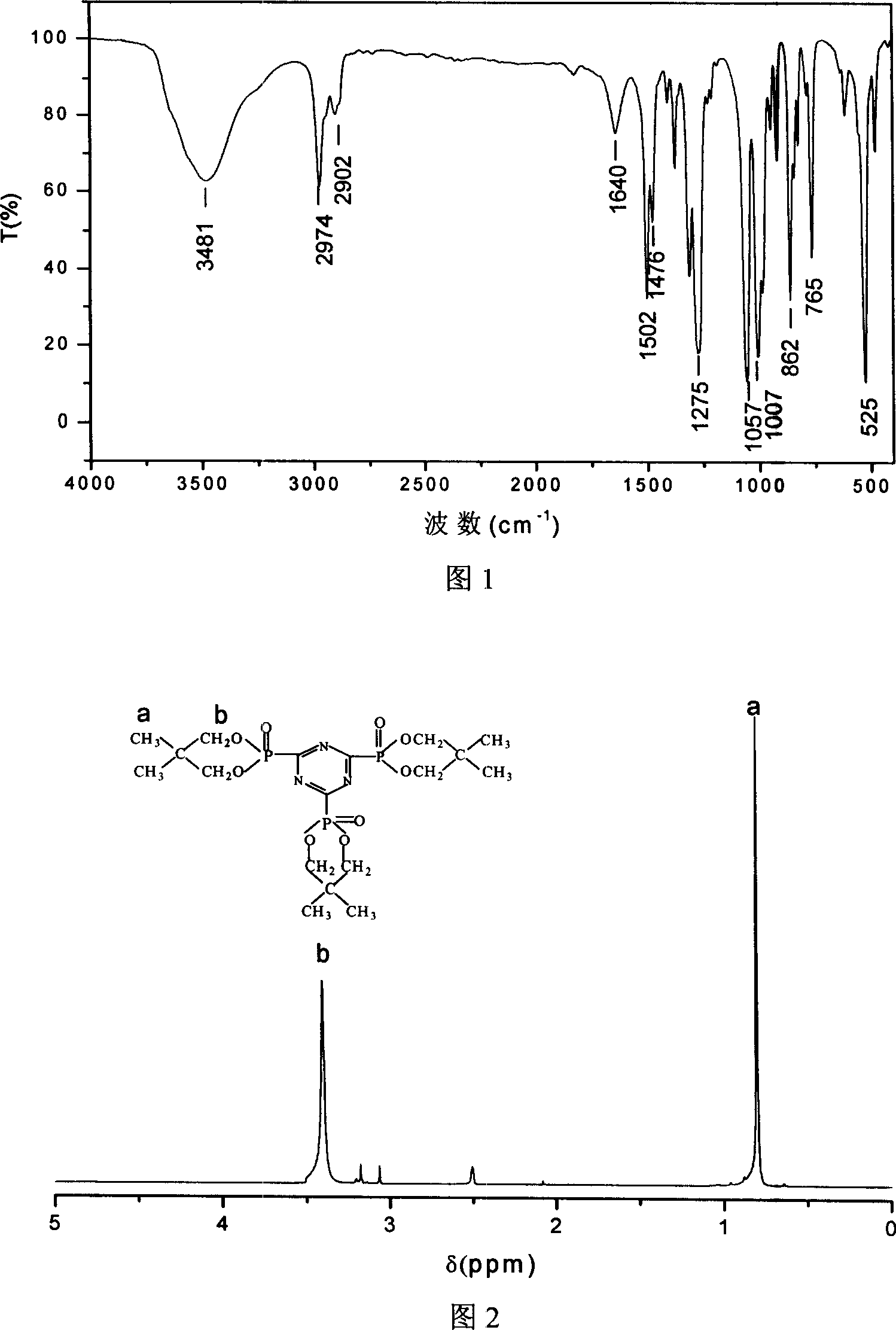

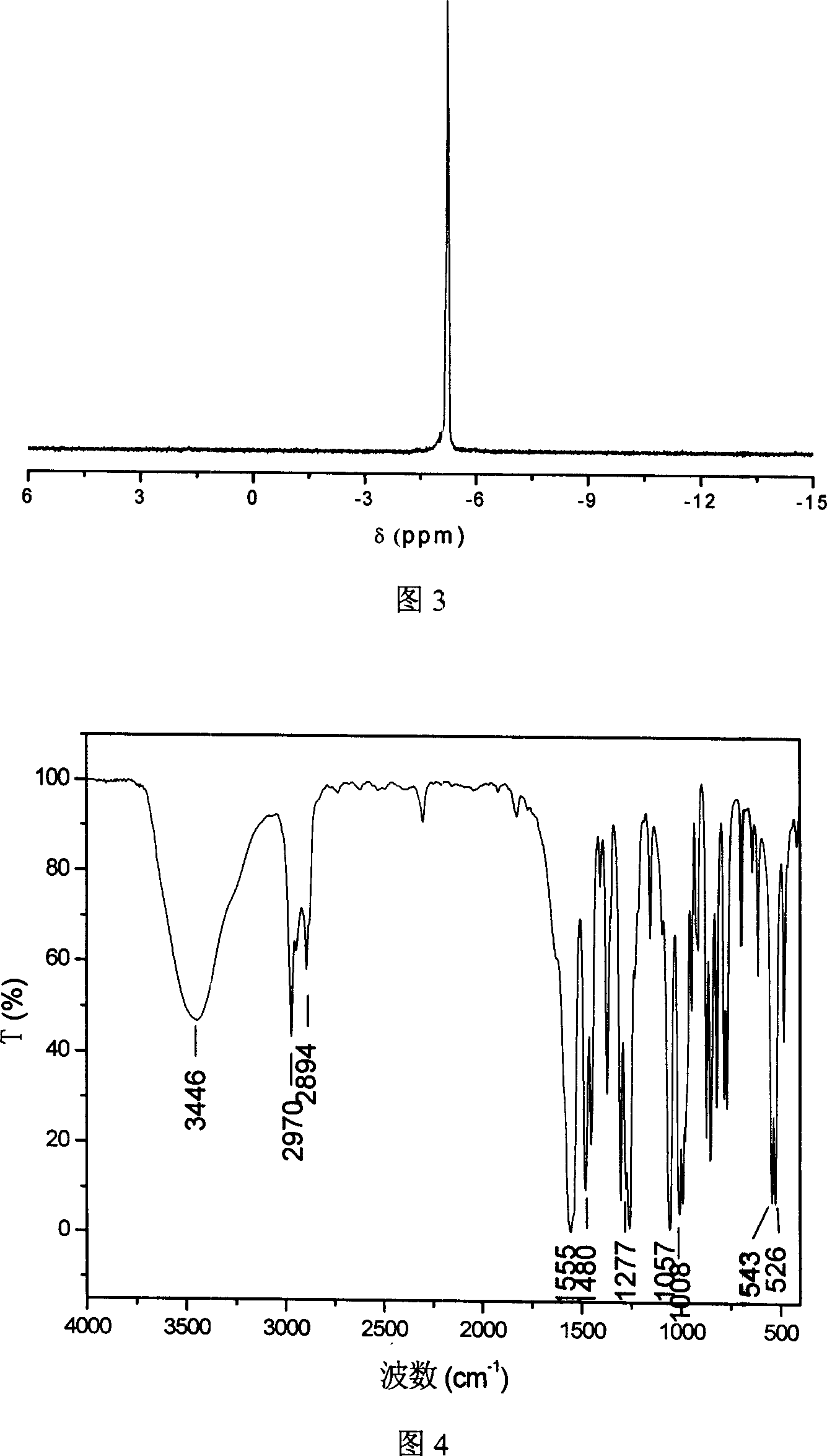

Embodiment 1

[0037] (1) Preparation of 1,3,5-triazine cycloneopentyl glycol phosphate: 36.9g (0.2mol) cyanuric chloride and 600g toluene are added to a 1000mL device equipped with magnetic stirring, condenser, constant pressure dropwise Four-neck flask with funnel and thermometer. The reaction system was kept at room temperature with a water bath, and 103.3 g (0.63 mol) of neopentyl glycol ethyl phosphite was added dropwise to the system in about 2 hours. When the dropwise addition was completed, the reaction system was heated to reflux for 4h. During this process, crude product solids were produced when refluxed for about 10 minutes. After the reaction was complete, the mixture was cooled to room temperature. The resulting crude product was filtered, washed with toluene and n-hexane, and dried under vacuum at 40-50°C. The obtained crude product was recrystallized from absolute ethanol to obtain 96.7 g of white crystals of tris(neopentyl glycol cyclic phosphate)-1,3,5-triazine ring with...

Embodiment 2

[0040] (1) Preparation of 1,3,5-triazine cycloneopentyl glycol phosphate: a mixed solution of 36.9g (0.2mol) cyanuric chloride and 300g xylene and ethylbenzene was added to a 1000mL magnetic stirrer , a condenser, a constant pressure dropping funnel and a four-neck flask with a thermometer. The reaction system was kept at room temperature with a water bath, and 94.8 g (0.63 mol) of neopentyl glycol methyl phosphite was added dropwise into the system in about 3 hours. After the dropwise addition was completed, the reaction system was heated to 140° C. for 2 h. During this process, crude product solids were produced when refluxing for about 5 minutes. After the reaction was complete, the mixture was cooled to room temperature. The resulting crude product was filtered, washed with xylene and n-hexane, and dried under vacuum at 40-50°C. The obtained crude product was recrystallized with absolute ethanol to obtain 88.7 g of light yellow crystal tris(neopentyl glycol cyclic phosp...

Embodiment 3

[0043] (1) Preparation of 1,3,5-triazine cycloneopentyl glycol phosphate: 36.9g (0.2mol) cyanuric chloride and 900g N, N-dimethylformamide were added to a 1000mL magnetic stirrer , constant pressure dropping funnel and a four-necked flask with a thermometer. The reaction system was kept at room temperature with a water bath, and 112.1 g (0.63 mol) of neopentyl glycol isopropyl phosphite was added dropwise to the system in about 3 hours. After the dropwise addition was completed, the reaction system was reacted at 40° C. for 10 h. After the reaction was complete, the mixture was cooled to room temperature. The solvent was distilled from the product mixture under reduced pressure, and the obtained crude product was recrystallized from absolute ethanol to obtain 55.8 g of light yellow crystal tris(neopentyl glycol cyclic phosphate)-1,3,5-triazine ring, with a yield of 53.2%.

[0044] (2) Preparation of phosphorus-containing triazine ring flame retardant: install magnetic stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com