Intumescent flame retardant and synthesis method thereof

An intumescent flame retardant and a synthesis method technology, applied in the field of flame retardants, can solve the problems of small content of effective flame retardant components, low flame retardant efficiency, unfavorable storage and storage, etc., and achieve good compatibility and easy Control, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 8.32g (0.08mol) of neopentyl glycol and 30mL of chloroform into a 100mL four-necked reaction flask equipped with a thermometer, a reflux condenser, a magnetic stirrer, and an exhaust gas absorption device, stir well to dissolve the neopentyl glycol, and then Add 8.32mL (0.08mol) of phosphorous trichloride dropwise to the reaction flask, after 2 hours, the reaction temperature was gradually raised to 50°C, and the reaction was completed for 3 hours, then the reaction was terminated, distilled under reduced pressure, washed with water, and dried in vacuum for 12 hours to obtain a white Solid, 2-thio-2-chloro-5,5-dimethyl-1,3,2-dioxaphosphorinane, yield 75.5%.

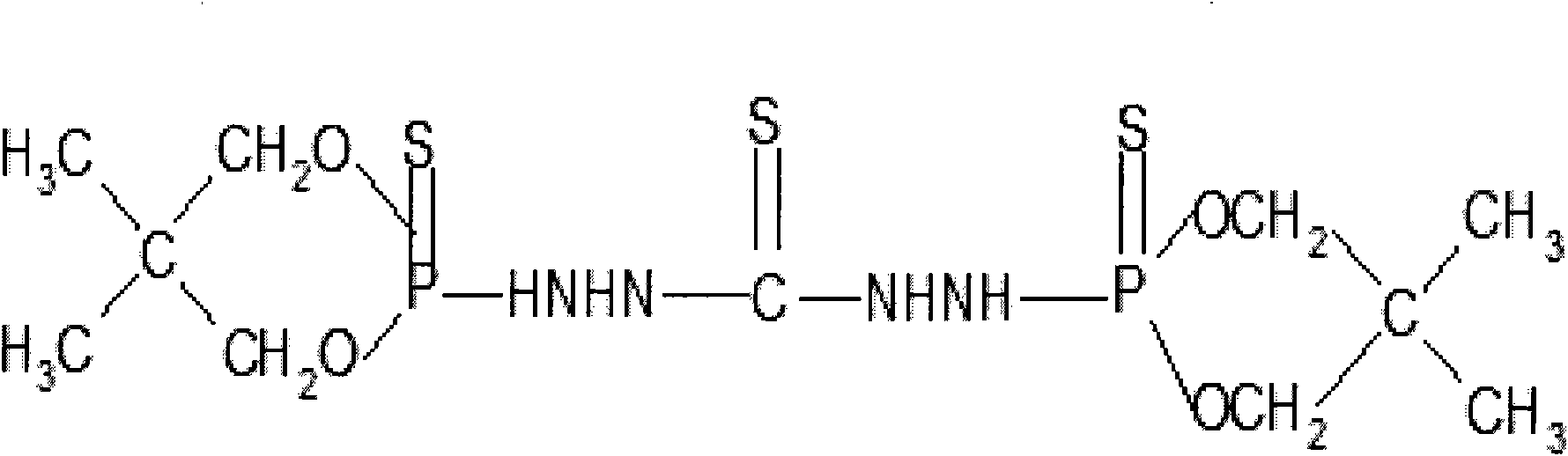

[0032]Weigh 36g (0.18mol) of 2-thio-2-chloro-5,5-dimethyl-1,3,2-dioxaphosphorinane and? In a 250mL four-necked reaction flask, add 100mL DMF, stir rapidly to dissolve it, then add 9.54g (0.09mol) of dithiosemicarbazide, 26.01mL (0.18mol) of triethylamine, heat to 50°C, React for 4 hours, stop the reaction, fil...

Embodiment 2

[0034] The molar ratio of neopentyl glycol to phosphorus trichloride in this embodiment is 1.25:1. In the synthesis process, after the phosphorus trichloride is added dropwise, the reaction temperature rises to 75° C., and the reaction time is 4 hours. The rest are the same as in Example 1.

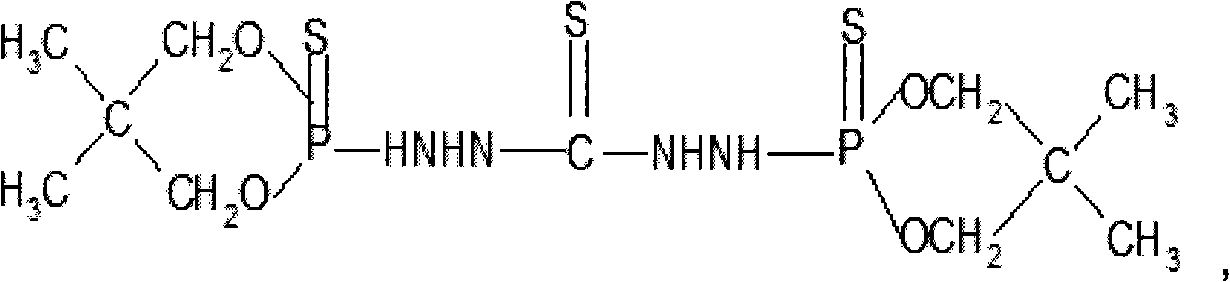

[0035] The yield of 2-thio-2-chloro-5,5-dimethyl-1,3,2-dioxaphosphorinane in this example is 78.6%; N, N'-two (5, The yield of 5-dimethyl-2-phospha-2-thio-1,3-dioxan-2-yl)dithiosemicarbazide was 72.7%.

Embodiment 3

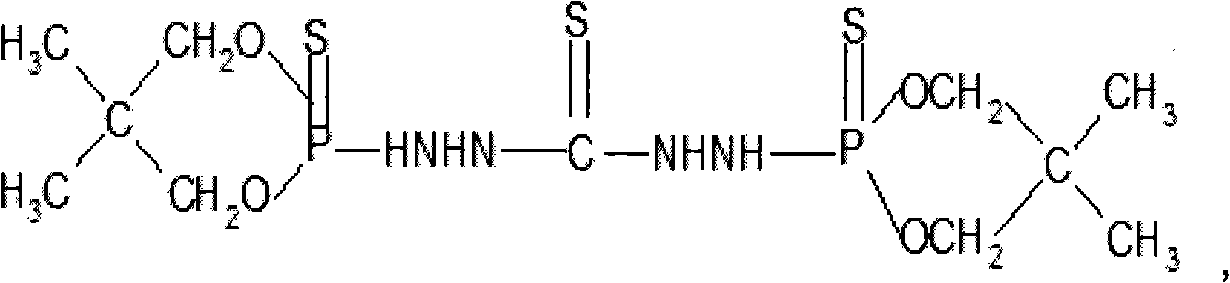

[0037] The molar ratio of neopentyl glycol to phosphorus trichloride in this embodiment is 1.25:1. In the synthesis process, after the addition of thion trichloride is completed, the reaction temperature rises to 75°C, and the reaction time is 6 hours. 2-thio-2-chloro-5,5-dimethyl-1,3,2-di The molar ratio of oxaphosphorinane to dithioaminourea is 2: 1.2, and all the other are the same as in Example 1.

[0038] The yield of 2-thio-2-chloro-5,5-dimethyl-1,3,2-dioxaphosphorinane in this example is 78.6%; N, N'-two (5, The yield of 5-dimethyl-2-phospha-2-thio-1,3-dioxan-2-yl)dithiosemicarbazide was 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com