A kind of n-b synergistic high flame retardant curing agent and its synthesis method

A synthesis method and curing agent technology are applied in the field of N-B synergistic high flame retardant curing agent and its synthesis field to achieve the effects of solving the problems of flame retardancy and flame retardant durability, easy compatibility and good flame retardant durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

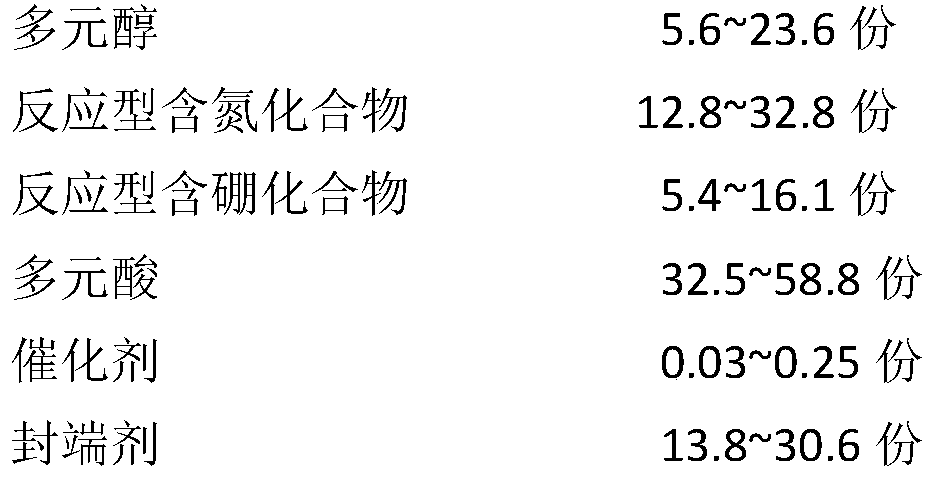

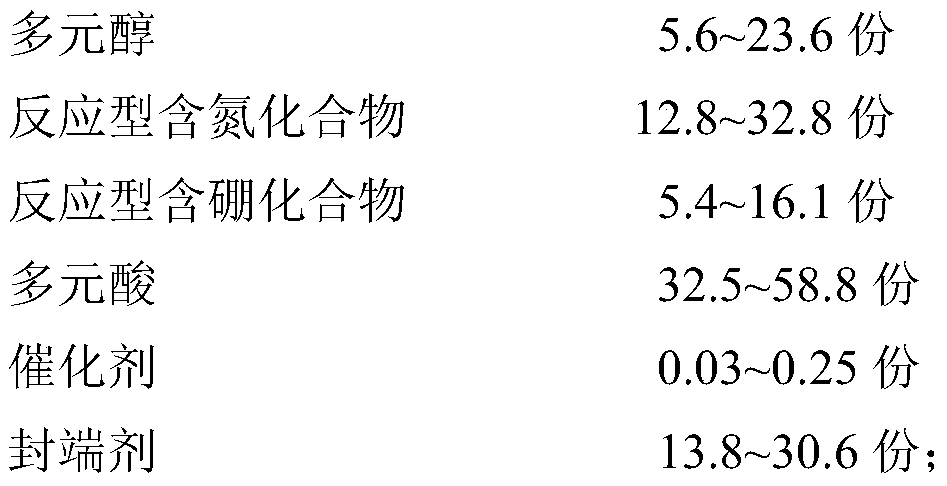

Method used

Image

Examples

Embodiment 1

[0034] A kind of synthetic method of N-B synergistic high flame retardant curing agent (A), the steps are as follows:

[0035] (1) After finishing the four-neck flask, stirrer, distillation column, condenser tube and temperature-controlled heating mantle, add 120g of neopentyl glycol and 168.21g of 1,3-dimethylol-5,5-dimethylhydantoin, and raise the temperature To 110~130℃, stirring and melting;

[0036] (2) Add 85.48g of 3-carboxyphenylboronic acid and 0.37g of ethyltriphenylphosphine bromide; slowly raise the temperature to 150°C under nitrogen, and distill out by-product water. During the reaction, control the temperature of the distillation column to not exceed 100°C, and then carry out segmented esterification reaction, 150~160°C for 1~3h, 160~170°C for 1~2h;

[0037](3) Cool down to 150°C, add 248.83g of isophthalic acid, 84.18g of adipic acid and 0.33g of ethyltriphenylphosphine bromide, slowly raise the temperature to 150°C under nitrogen, and carry out a segmented es...

Embodiment 2

[0042] A kind of synthetic method of multi-branched N-P synergistic flame retardant flexible curing agent (B), the steps are as follows:

[0043] (1) After finishing the four-neck flask, stirrer, distillation column, condenser tube and temperature-controlled heating mantle, add 105g of neopentyl glycol and 184.33g of 1,3-dimethylol-5,5-dimethylhydantoin, and raise the temperature To 110 ~ 130 ℃, stir and melt;

[0044] (2) Add 76.32g of 3-carboxyphenylboronic acid and 0.36g of ethyltriphenylphosphine bromide; slowly raise the temperature to 150°C under nitrogen, and distill out by-product water. During the reaction, control the temperature of the distillation column to not exceed 100°C, and then carry out segmented esterification reaction, 150~160°C for 1~3h, 160~170°C for 1~2h;

[0045] (3) Cool down to 150°C, add 239.26g of isophthalic acid, 105.23g of adipic acid and 0.34g of ethyltriphenylphosphine bromide, slowly raise the temperature to 150°C under nitrogen, and carry o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com