System for determining steam-gas ratio of inlets of all shift converters at conversion section of tandem type synthesis ammonia plant

A measurement system and a technology for conversion furnaces, which are applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as the inability to measure the ratio of gas to gas, the increase of measurement costs, and the inability to measure the ratio of gas to gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

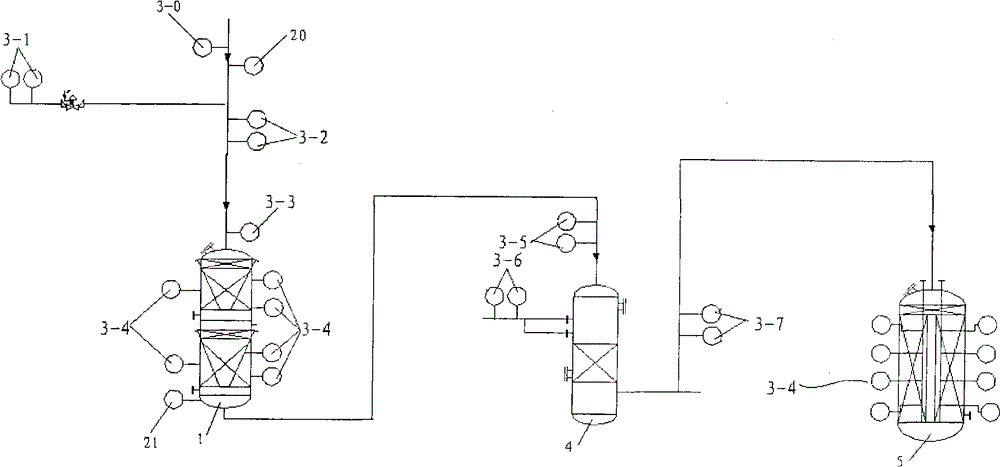

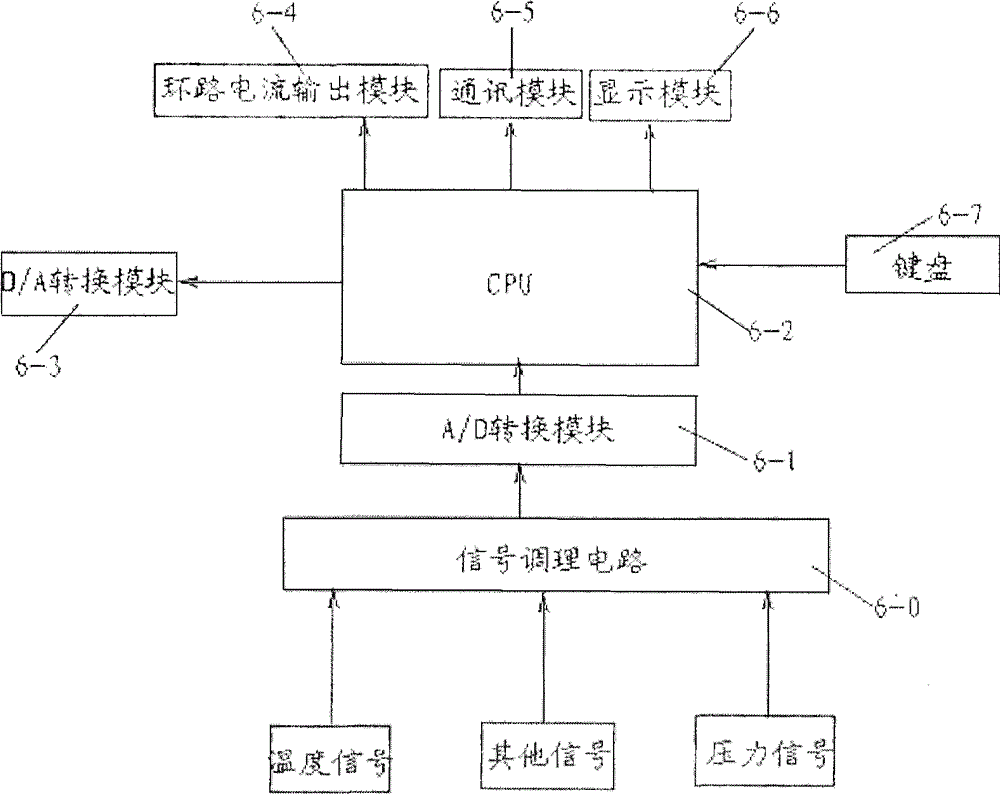

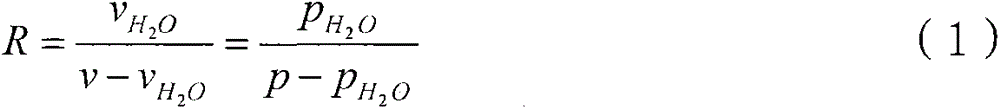

[0051] Determination of the steam-to-gas ratio at the inlet of the first conversion furnace section 1: since the first conversion furnace section 1 does not have the previous section, there is no conversion reaction of formula (2), at this time, the temperature sensor 3-3 measures the first conversion furnace section 1 The temperature T0 of the inlet, and the hot spot temperature detection sensor group 3-4 are connected to a point of the inlet cold gas pipeline. The present invention becomes a method for determining the ratio of steam and dry gas in the process of adding steam disclosed in the prior art, and the steam-gas ratio can be measured as R 0 , and communicate with the device of the present invention at the entrance of the second conversion furnace section 5 through the field bus.

Embodiment 2

[0053] The steam-gas ratio measurement of the second stage conversion furnace section 5 entrance: obtain the component Yi of furnace gas by semi-water gas component analyzer 20 at the entrance; Embodiment 1 obtains that the steam-gas ratio of the first section conversion furnace section entrance is R 0 ; The following reaction took place in the first stage shift furnace section 1:

[0054]

[0055] At this time, the hot spot temperature detection sensor group 3-4 inserted into the catalyst layer; the temperature at the highest temperature point is selected as the hot spot temperature T by comparison, and "T+balanced temperature distance" is substituted into formula (3) to calculate K p , plus formula (4) ~ (10) to get the steam-gas ratio at the outlet of section 1 of the first conversion furnace. Between the first conversion furnace section 1 and the second conversion furnace section 5, water is usually sprayed for cooling to adjust the temperature and increase water vapor....

Embodiment 3

[0059] Obtain the gas-to-gas ratio of the second stage shift furnace section 5 inlets from embodiment 2, since there is no water spray and steam addition between the second stage shift furnace section 5 outlet and the third shift furnace section inlet, so by formula (11) and (12) obtain X=0; Only need obtain R by above-mentioned algorithm 1 , ie R=R 1 That is the ratio of steam into the furnace in the third stage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com