Synthesis gas preparing system and method

A preparation system and synthesis gas technology, applied in the field of synthesis gas preparation system, can solve the problems of insufficient utilization of raw materials, high energy consumption per unit output, low conversion efficiency, etc., to improve conversion efficiency and yield, reduce energy consumption, and ensure safety sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

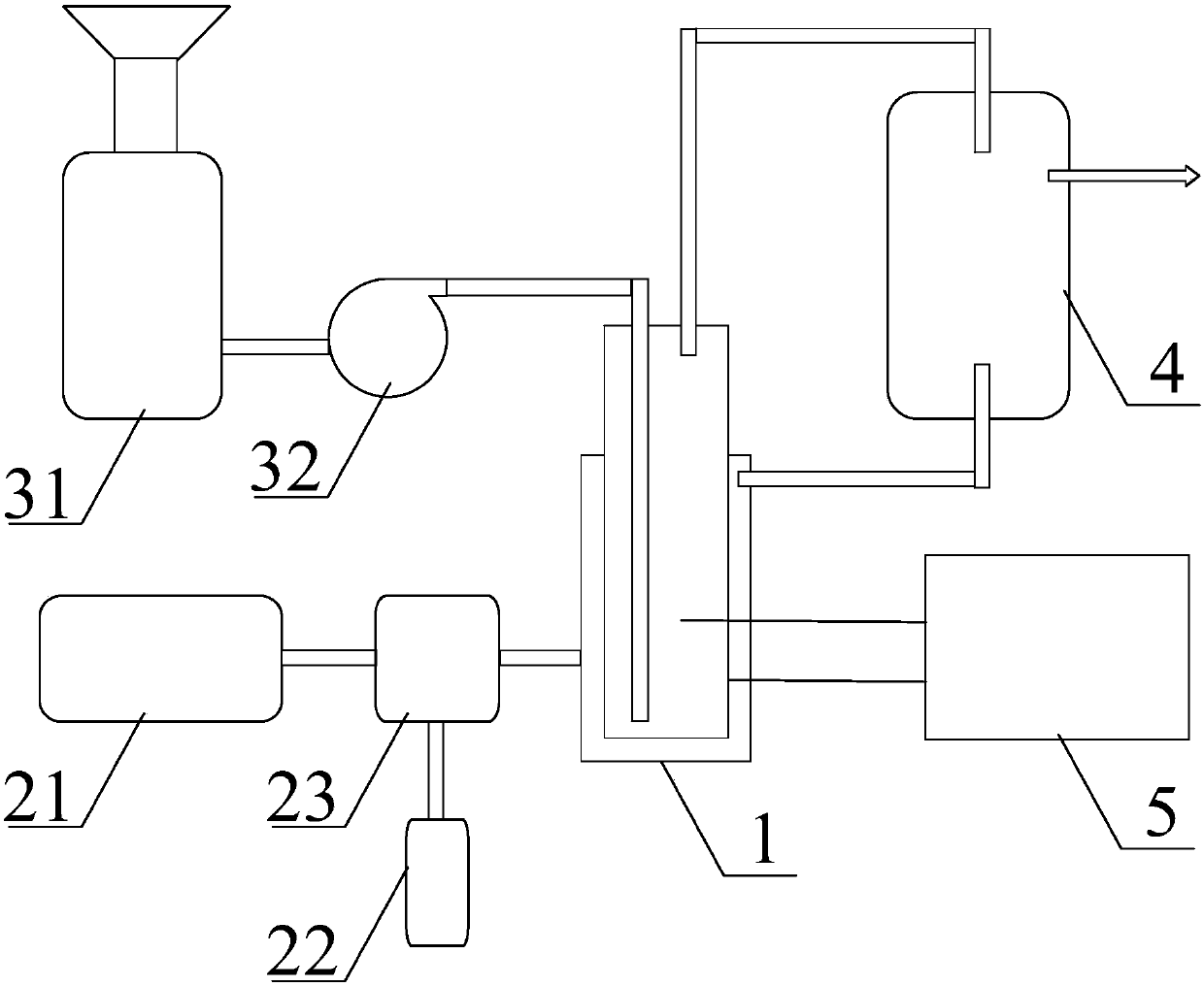

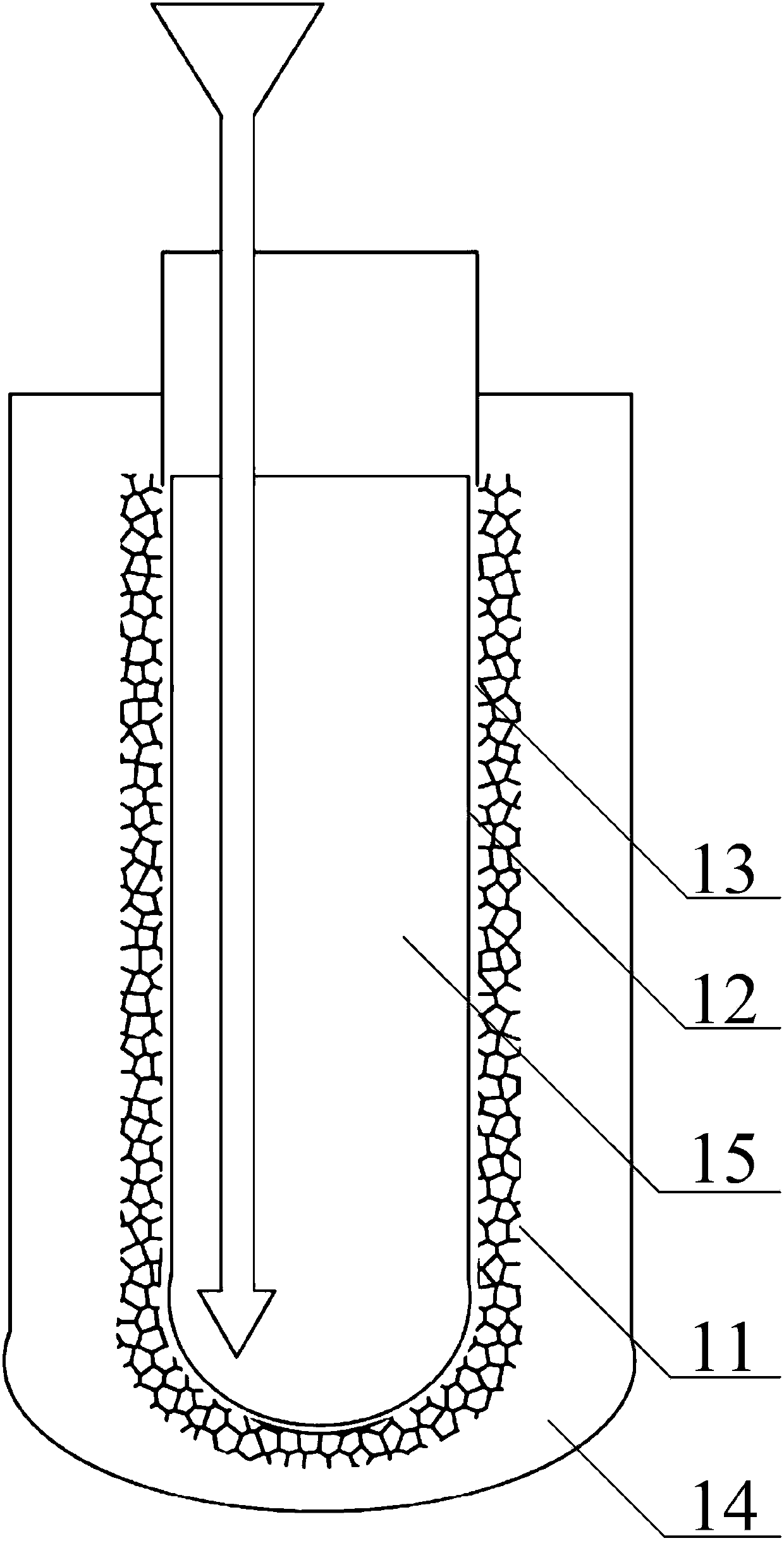

[0059] Such as figure 1 As shown, this embodiment provides a synthesis gas preparation system, which includes a solid oxide electrolytic cell 1, a raw material gas supply system, a molten salt supply system, and a synthesis gas mixing chamber 4. In addition, an external direct current is also provided. Power source 5; the cathode of the solid oxide electrolytic cell 1 is connected to the negative electrode of the external DC power source 5, the anode of the solid oxide electrolytic cell 1 is connected to the anode of the external DC power source 5, and the raw gas supply system includes steam generation The steam generator 21 and the protective gas cylinder group 22 are respectively connected to the gas mixing chamber 23, and the gas mixing chamber 23 is connected to the gas mixing chamber 23. The cathode compartment of the solid oxide electrolytic cell 1 is connected, and the molten salt supply system includes a carbon powder / molten salt mixer 31 and a molten salt circulating p...

Embodiment 2

[0068] The structure of the synthesis gas preparation system and the solid oxidation electrolytic cell of this embodiment is the same as that of Embodiment 1, except that this embodiment includes a plurality of tubular solid oxide electrolytic cells, and the specific parameters of the electrolytic cell and the synthesis gas preparation method are different.

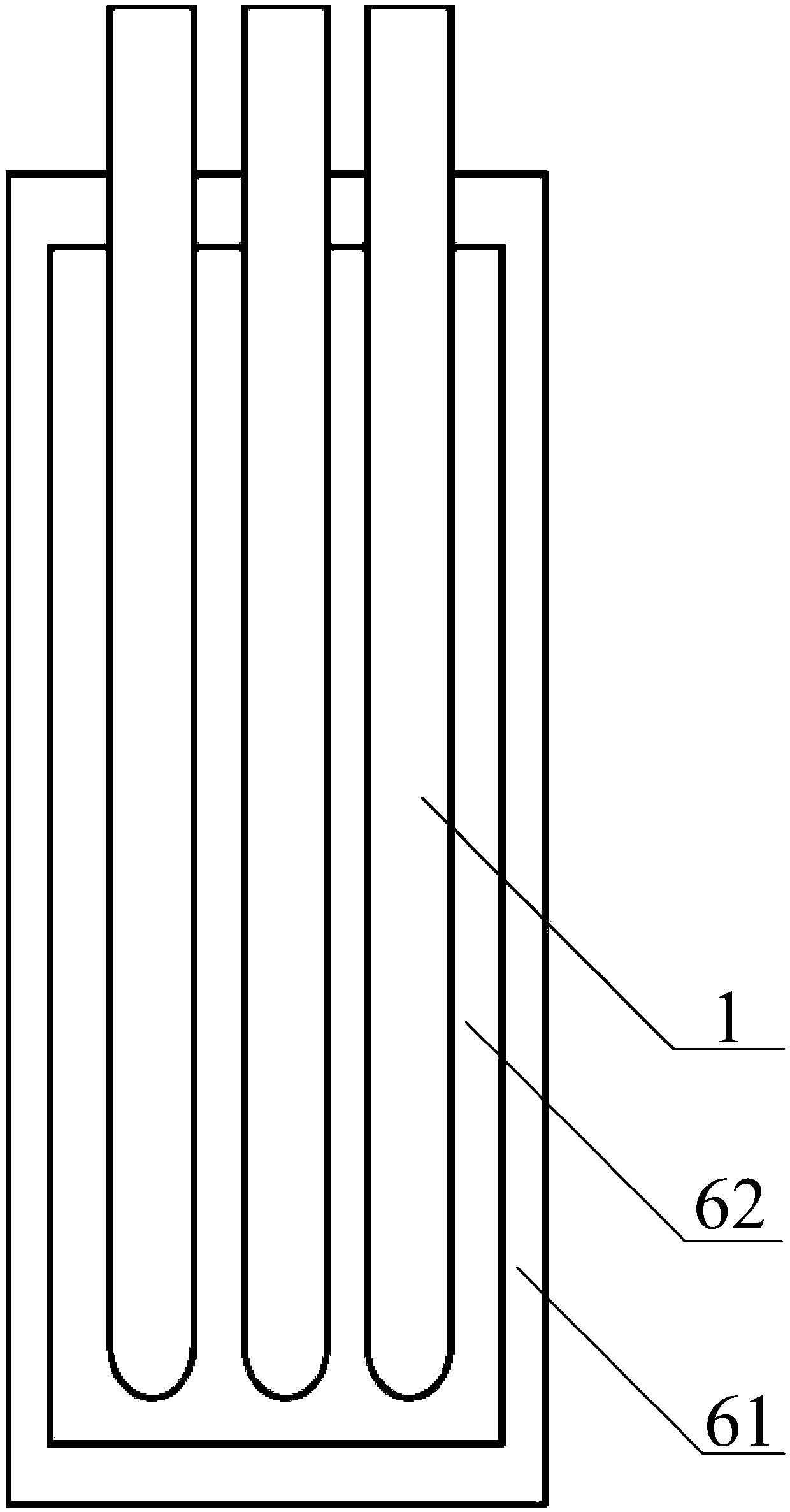

[0069] Such as image 3 As shown, the solid oxide electrolytic cell 1 is set in a hot box. The hot box includes a box 61 and an insulation layer 62 provided on the inner wall of the box. The outer shell of the box 61 is made of steel plate. The thickness of the steel plate is 20 mm, the material of the thermal insulation layer is quartz wool, and the thickness of the thermal insulation layer is 10 cm. The synthesis gas reactor in this example is equipped with 10 serial tubular solid oxide electrolytic cells ( image 3 The section does not show all tubular solid oxide electrolytic cells), and the individual electrolytic cells ...

Embodiment 3

[0073] The structure of the synthesis gas preparation system and solid oxidation electrolytic cell of this embodiment is the same as that of embodiment 1, the difference lies in:

[0074] (1) In the synthesis gas preparation system of this embodiment, the anode is an LSM thin film electrode;

[0075] (2) In the synthesis gas preparation method of this embodiment, the molten salt is CaCl 2 / NaCl mixed system molten salt, in which the Fe catalyst content is 0.5%, and the working temperature of the solid oxide electrolytic cell is 900°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com