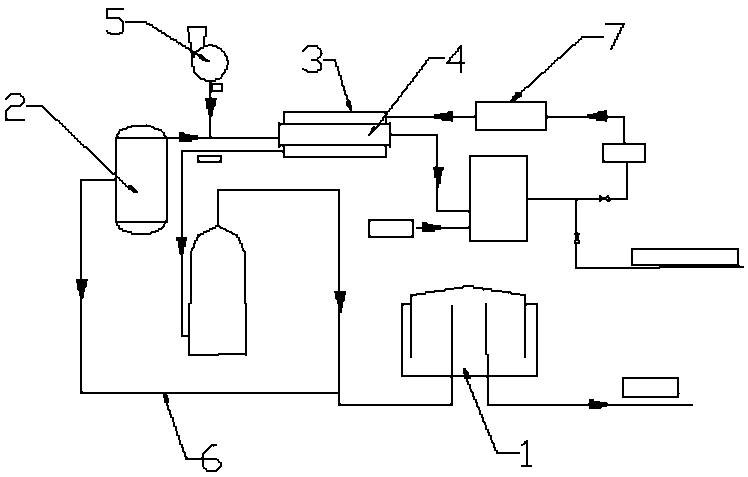

Energy-saving type synthesis ammonia semi-oxygen-enriched gas making device and process

A gas-making device and a technology for synthesizing ammonia, which is applied in the direction of gasification process, manufacture of combustible gas, sustainable manufacturing/processing, etc., can solve the problems of system hydrogen-nitrogen ratio fluctuation, high investment, and difficult realization, etc., and achieve reduction of slag carbon content, High degree of functionalization and stable gas composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention provides an energy-saving semi-oxygen-enriched synthetic ammonia gas-generating device. The proportion of CO2 in the process gas is reduced by 3%-4%, so that the efficiency of the synthetic ammonia production system is improved and the electricity consumption per unit of synthetic ammonia is greatly reduced; Fully reduce the carbon content of the slag to 7%-9%, greatly reducing the carbon content of the slag; due to the increase of the blowing content and the reduction of the pressure, the requirements for the quality and particle size of the coal are reduced, the working conditions of the blowing process are stable, and the working efficiency of the gas-making fan is high. Power consumption Low, because the stable gas composition of the process gas is conducive to the stable production of the entire production system, the equipment investment is small, the nitrogen production system is highly functional, and the safety factor is high.

[0025] In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com