Catalyst for directly manufacturing low-carbon olefin through nuclear shell type synthesis gas and preparation method and application

A low-carbon olefin and catalyst technology, which is applied in the application field of low-carbon olefin synthesis, can solve problems such as catalyst differences, and achieve the effects of short crystallization time, large pore volume, and adjustable shell thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

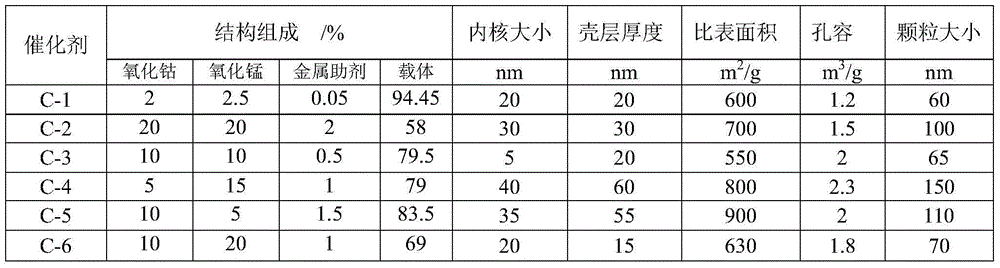

Examples

Embodiment 1

[0022] 300ml 10wt%Co(NO 3 ) 3 ·6H 2 O and 200ml 10wt% Mn(NO 3 ) 2 The solution was mixed, and then added ruthenium chloride to make the content 0.05wt%, and then it was mixed with 500ml NH 3 ·H 2 O (25-28wt%) solution is co-precipitated in parallel, and the precipitate is aged, washed and filtered to obtain a mixture of Co and Mn.

[0023] With tetrapropyl ammonium hydroxide TPAOH as structure directing agent, the molar ratio of sol is 1.0TEOS:0.25TPAOH:0.025((CH 3 ) 2 CHO) 3 Al:50H 2 O:2EtOH. These substances were sequentially added to a stainless steel reaction kettle lined with polytetrafluoroethylene, and stirred at 60°C and 10 rpm for 2 hours until a bright yellow uniform sol was formed to obtain 150ml sol. Then add Co and Mn mixture precipitates into the sol, stir evenly, and crystallize at 120°C and 10rpm for 10h. After natural cooling, wash the filtrate repeatedly with deionized water until the pH value is 7.9, dry at 60°C for 12 hours, and roast at 450°C fo...

Embodiment 2

[0026] 500ml 10wt%Co(NO 3 ) 3 ·6H 2O and 300ml 50wt% Mn(NO 3 ) 2 The solution is mixed, and then a certain amount of lanthanum nitrate is added to make the content 2wt%, and then it is mixed with the mixed solution with an equal volume of NH 3 ·H 2 O (25-28wt%) solution is co-precipitated in parallel, and the precipitate is aged, washed and filtered to obtain a mixture of Co and Mn.

[0027] With tetrapropyl ammonium hydroxide TPAOH as the structure-directing agent, the molar ratio of the sol is 3TEOS:0.5TPAOH:0.06((CH 3 ) 2 CHO) 3 Al:80H 2 O:5EtOH. These substances were sequentially added to a stainless steel reaction kettle lined with polytetrafluoroethylene, stirred at 80°C and 20 rpm for 4 hours until a bright yellow uniform sol was formed, and 200ml of sol was obtained. Add the precipitated Co and Mn mixture into the sol, stir evenly, and crystallize at 180°C and 30rpm for 20h. After natural cooling, wash the filtrate repeatedly with deionized water until the p...

Embodiment 3

[0030] 350ml 15wt%Co(NO 3 ) 3 ·6H 2 O and 300ml 50wt% Mn(NO 3 ) 2 The solution was mixed, and then a certain amount of chloroplatinic acid was added to make the content 0.5wt%, and then it was mixed with the mixed solution with an equal volume of NH 3 ·H 2 O (25-28wt%) solution is co-precipitated in parallel, and the precipitate is aged, washed and filtered to obtain a mixture of Co and Mn.

[0031] With tetrapropyl ammonium hydroxide TPAOH as structure directing agent, the molar ratio of sol is 1.5TEOS:0.3TPAOH:0.03((CH 3 ) 2 CHO) 3 Al:50H 2 O:2EtOH. These substances were sequentially added to a stainless steel reaction kettle lined with polytetrafluoroethylene, stirred at 60°C and 15 rpm for 2 hours until a bright yellow uniform sol was formed, and 150ml of sol was obtained. Add the precipitated Co and Mn mixture into the sol, stir evenly, and crystallize at 120°C and 15rpm for 12h. After natural cooling, wash the filtrate repeatedly with deionized water until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com