Antibacterial nano fiber material and preparation method thereof

A technology of nanofibers and antibacterial agents, applied in the field of nanofibers and their preparation, can solve the problems of unsatisfactory filtration effect of particles carrying pathogenic bacteria, large fiber pore size, etc., and achieve good drug dispersion, ultra-high specific surface area, and filtration good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

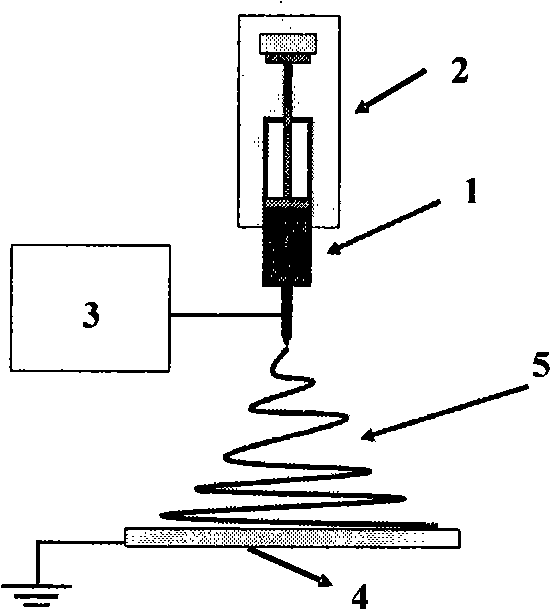

[0032] Dissolve 0.05g of tetracycline hydrochloride in 1.0mL of distilled water; dissolve 0.6g of polylactic acid PLA in 10mL of dichloromethane, then add 0.05g of sodium dodecylsulfonate, and disperse it evenly by ultrasonic vibration; mix the above two solutions Mix to obtain a homogeneous water-in-oil (W / O) emulsion.

[0033] Electrospinning was performed on the obtained emulsion so that the applied voltage was 20kv, the receiving distance was 12cm, the spinning speed was 1.0mL / h, and the diameter of the spinneret was 0.9mm.

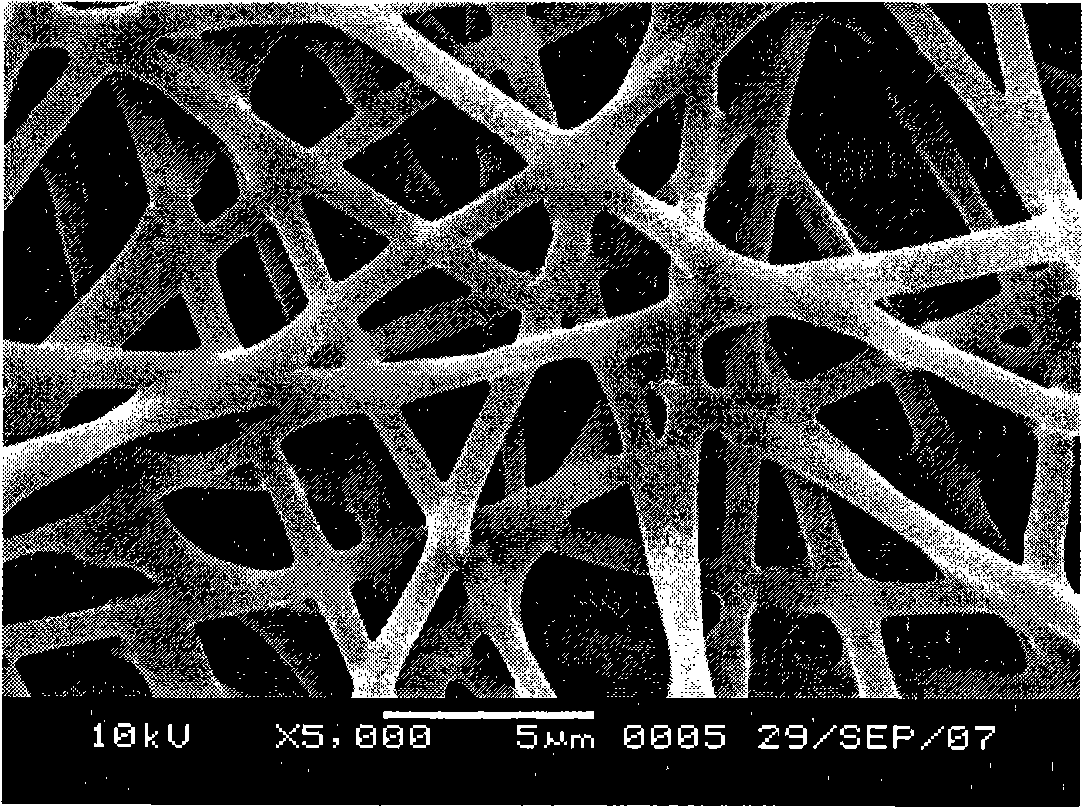

[0034] The diameter of the obtained nanofiber is between 200nm and 1600nm, and the fiber membrane can be seen to be light yellow of tetracycline hydrochloride when observed by naked eyes, indicating that tetracycline hydrochloride has been wrapped in it.

Embodiment 2

[0036] Dissolve 0.05g of penicillin in 1.0mL of distilled water; dissolve 0.6g of polylactic acid-caprolactone P(LLA-CL) [50:50] in 10mL of dichloromethane, then add 0.05g of SPAN-80, and ultrasonically shake The dispersion is uniform; the above two solutions are mixed to obtain a uniform W / O emulsion.

[0037] Electrospinning was performed on the obtained emulsion so that the applied voltage was 20kv, the receiving distance was 12cm, the spinning speed was 1.0mL / h, and the diameter of the spinneret was 0.9mm.

[0038] The diameter of the obtained nanofiber is between 400nm and 1200nm.

Embodiment 3

[0040]Dissolve 0.05g streptomycin in 1.0mL distilled water; dissolve 0.6g polylactic acid-caprolactone P(LLA-CL) [50:50] in 10mL dichloromethane, then add 0.05g SPAN-80, and ultrasonically shake Make it dispersed evenly; mix the above two solutions to obtain a uniform W / O emulsion.

[0041] Electrospinning was performed on the obtained emulsion so that the applied voltage was 20kv, the receiving distance was 12cm, the spinning speed was 1.0mL / h, and the diameter of the spinneret was 0.9mm.

[0042] The diameter of the obtained nanofiber is between 400nm and 1200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com