Cement kiln system capable of realizing zero emission of carbon dioxide and cement clinker preparation method

A carbon dioxide and cement kiln technology, applied in the treatment of discharged materials, cement production, carbon capture, etc., can solve the problems of low concentration, high system investment and operation cost, low gas capture efficiency, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

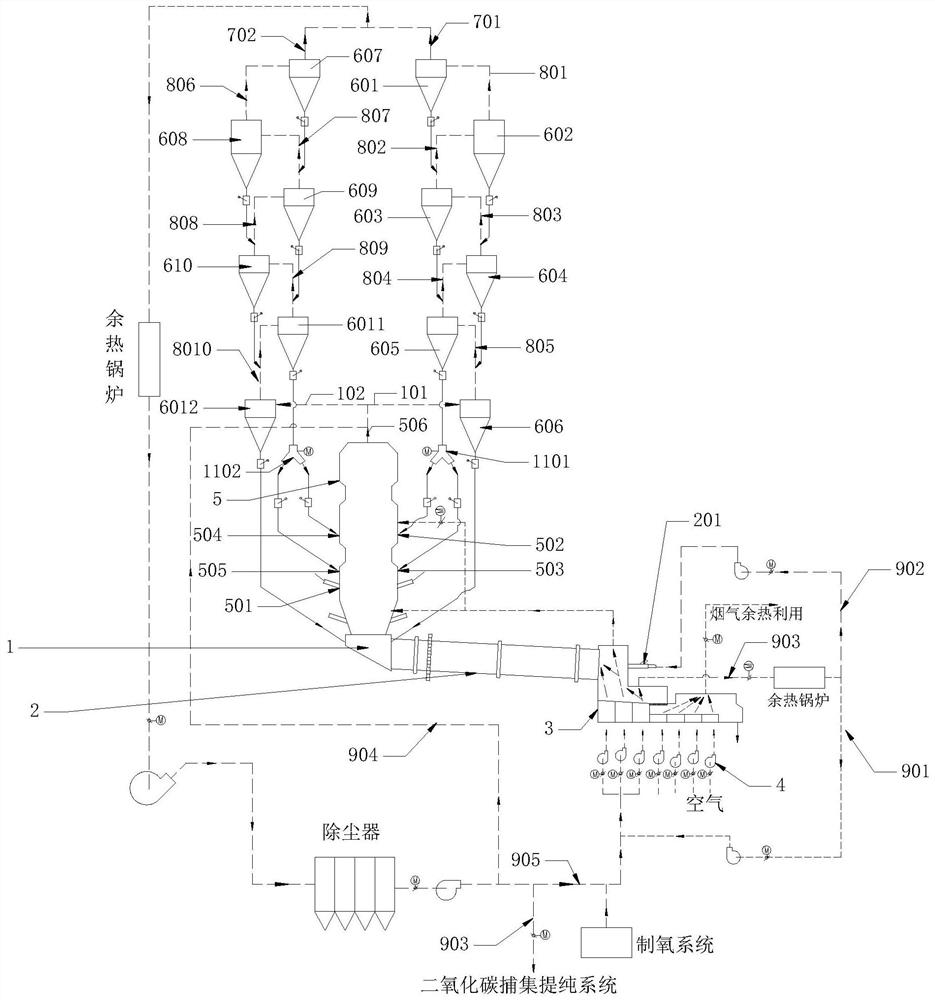

[0061] Such as figure 1 As shown, the cement kiln system for realizing zero emission of carbon dioxide in this embodiment includes a smoke chamber 1, a rotary kiln 2, a cooling machine 3, a fan 4, a raw material preheating and pre-decomposition system, a first pipeline assembly and a second pipe Road components, raw meal preheating and pre-decomposition system is a conventional raw meal preheating and pre-decomposition system.

[0062] The raw material preheating and pre-decomposition system is connected with the smoke chamber 1, the first burner 201 is installed on the rotary kiln 2, the tail of the rotary kiln 2 is connected with the smoke chamber 1, and the head of the rotary kiln 2 is connected with the cooler 1.

[0063] The raw material preheating and pre-decomposing system includes a calciner 5 and a cyclone preheater. The cyclone preheater includes a first row of cyclone preheaters and a second row of cyclone preheaters. It should be noted that the row of cyclone prehe...

Embodiment 2

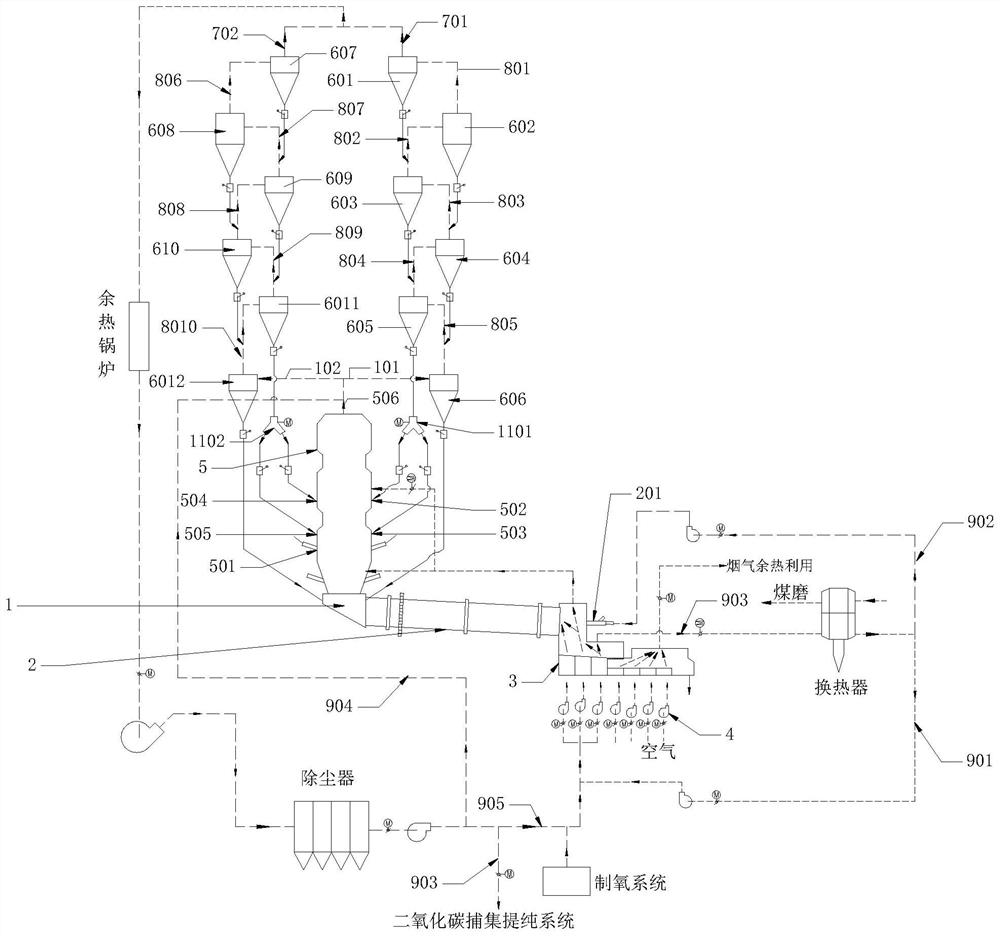

[0109] Such as figure 2 As shown, it is the cement kiln system of this embodiment to achieve zero emission of carbon dioxide, which is basically similar in structure to the cement kiln system of Embodiment 1, the difference is that the first waste heat utilization system of this embodiment includes a heat exchanger and a coal grinding device , that is, the first cooling gas in the third path exchanges heat with the air through the heat exchanger, and the air after heat exchange enters the coal mill for drying, and then is discharged into the atmosphere after being treated with flue gas. The gas after heat exchange is divided into The two paths enter the first branch pipeline 901 and the second branch pipeline 902 respectively.

[0110] The method for preparing cement clinker using the cement kiln system in this embodiment is the same as that in Embodiment 1.

Embodiment 3

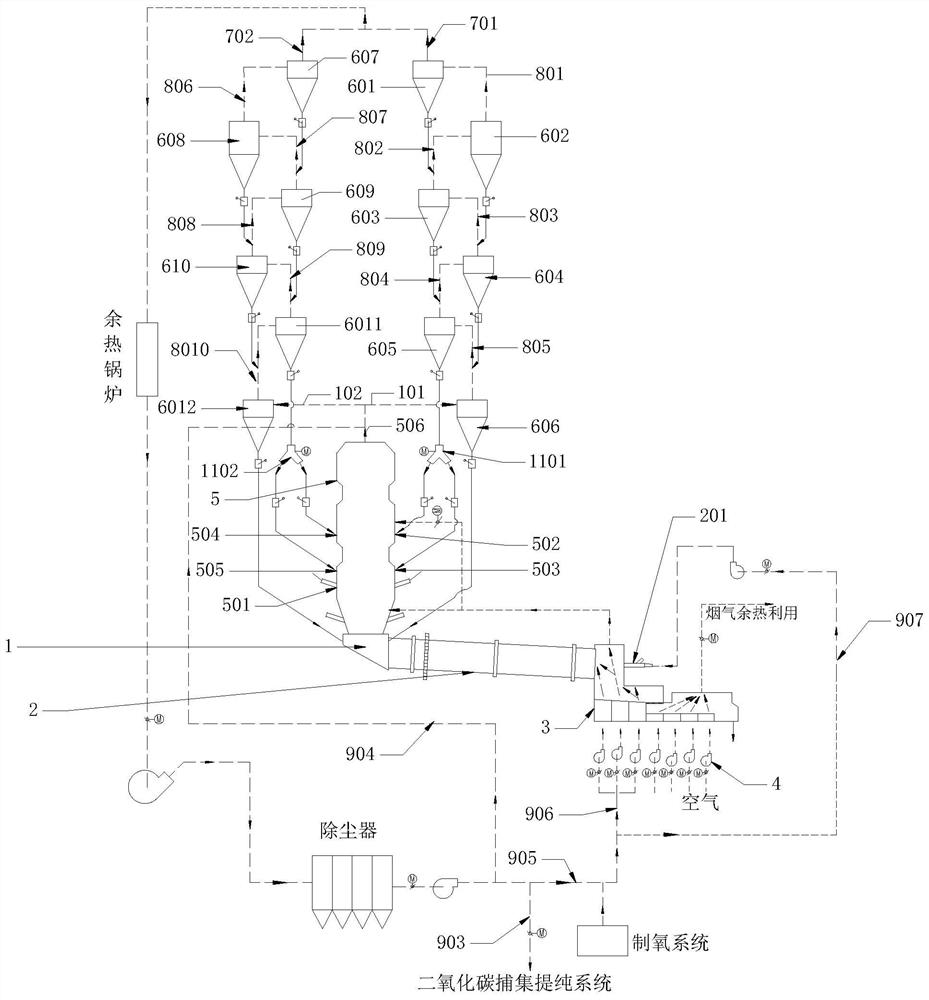

[0112] Such as image 3 As shown, the cement kiln system for realizing zero emission of carbon dioxide in this embodiment is basically similar to the structure of the cement kiln system in Embodiment 1, and the differences are as follows:

[0113] 1. The tolerance temperature of the middle roller breaker in the cooling machine 3 is ≥900°C, and the tolerance temperature of the middle roller breaker is ≥900°C. The roll breaker is generally located in the front section or the front middle section of the cooling machine 3. At this time, the first cooling gas is divided into Two way;

[0114] The first cooling gas from the first channel directly enters the rotary kiln as the secondary air for fuel combustion;

[0115] The first cooling gas of the second path enters the calciner as the tertiary air through the tertiary air duct for fuel combustion.

[0116]2. The other end of the fifth branch pipeline 905 is mixed with pure oxygen to obtain the mixed gas of pure oxygen and high-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com