An axial force measuring device and measuring method based on a tension-pressure sensor

A technology for measuring devices and axial forces, applied in measuring devices, force/torque/power measuring instruments, instruments, etc., can solve problems such as difficulty in implementation, accuracy of axial force needs to be verified, and influence of radial force cannot be ruled out. Achieve the effect of reducing the workload of modification and preventing rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

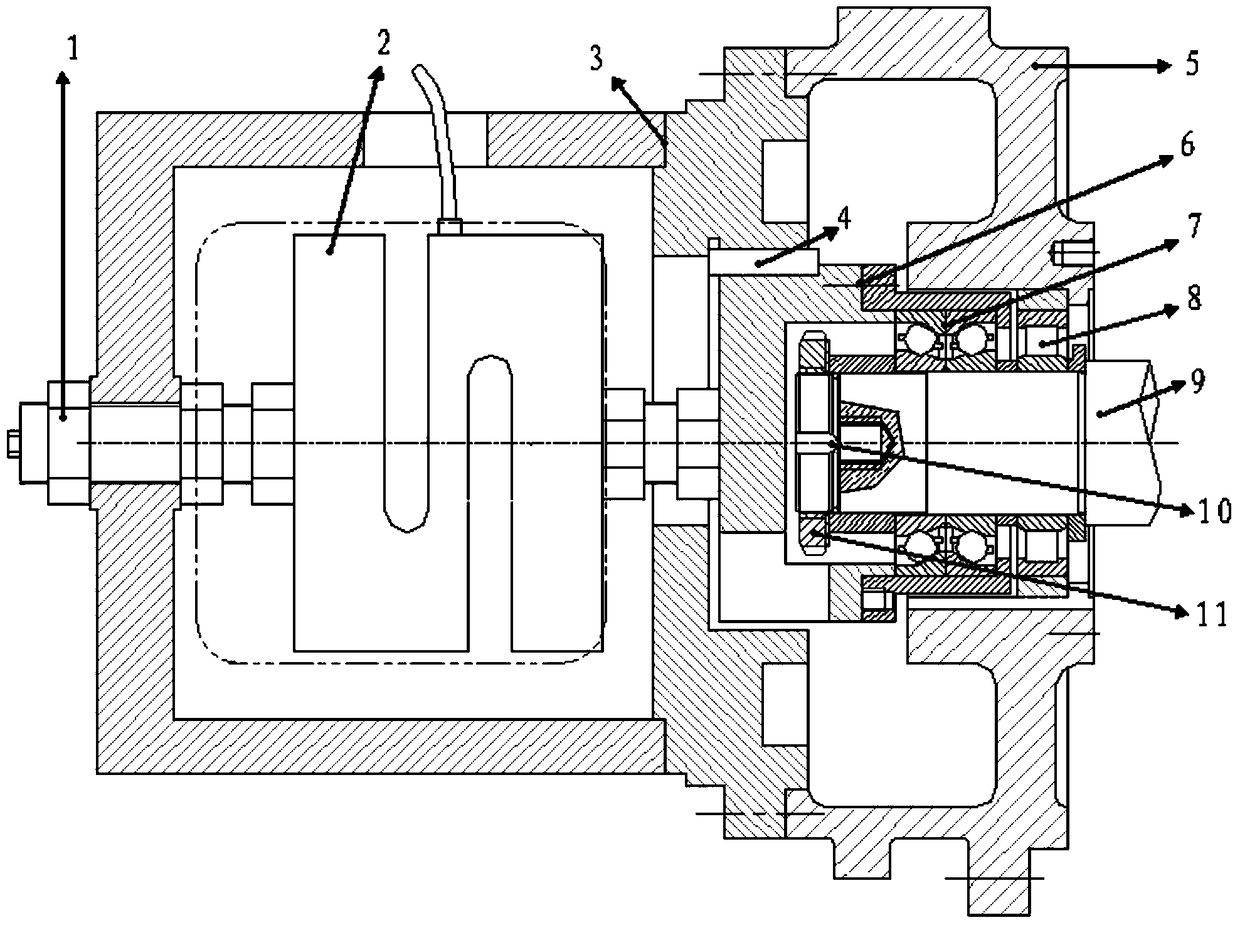

[0018] figure 1 It is a schematic diagram of the overall structure of the present invention. Such as figure 1 As shown: the axial force measuring device included in the present invention includes: adjusting and fixing nut 1, push-pull force gauge 2, dynamometer seat 3, key 4, bearing seat 5, axial force covering device 6, bearing group 7, Cylindrical roller bearing 8, shaft 9, shaft end screw 10 and lock nut 11, the bottom of the dynamometer seat 3 is fixed on the bearing seat 5 of the equipment under test by bolts; the top of the dynamometer seat 3 is fixed by adjusting and fixing the nut 1 Fix one end of the push-pull gauge 2; the other end of the push-pull gauge 2 is connected to the axial force covering device 6 through a nut; there is a gap between the axial force covering device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com