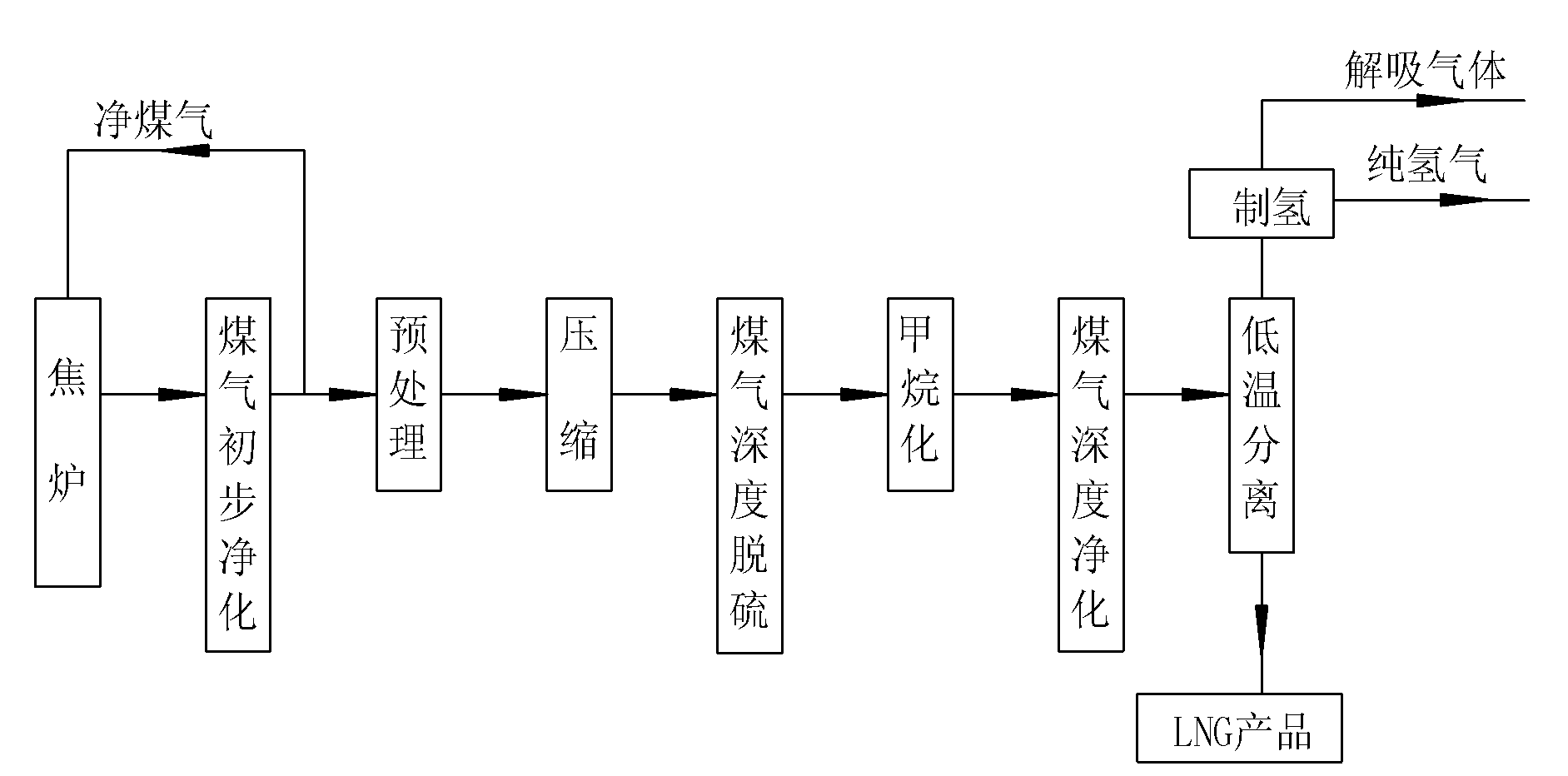

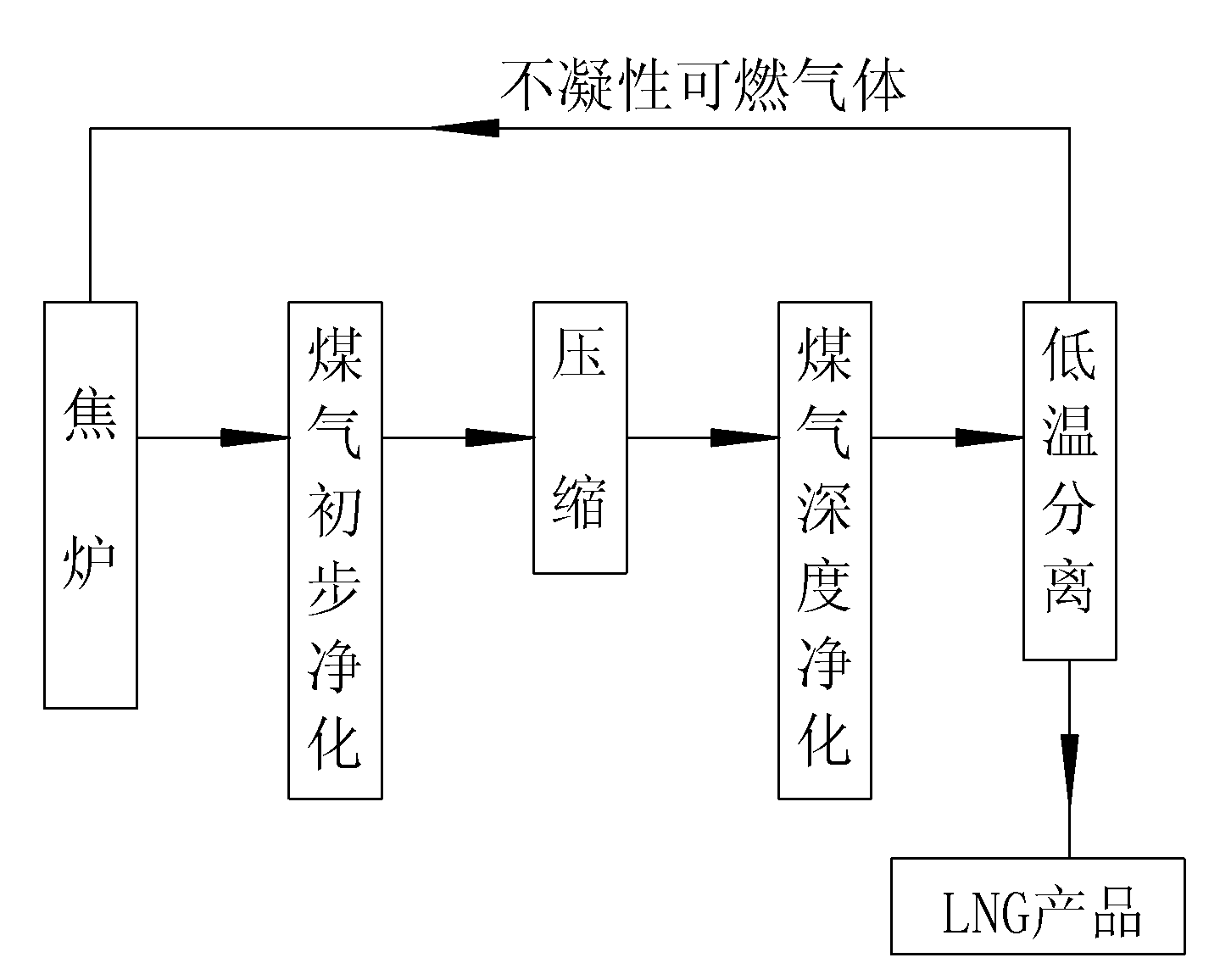

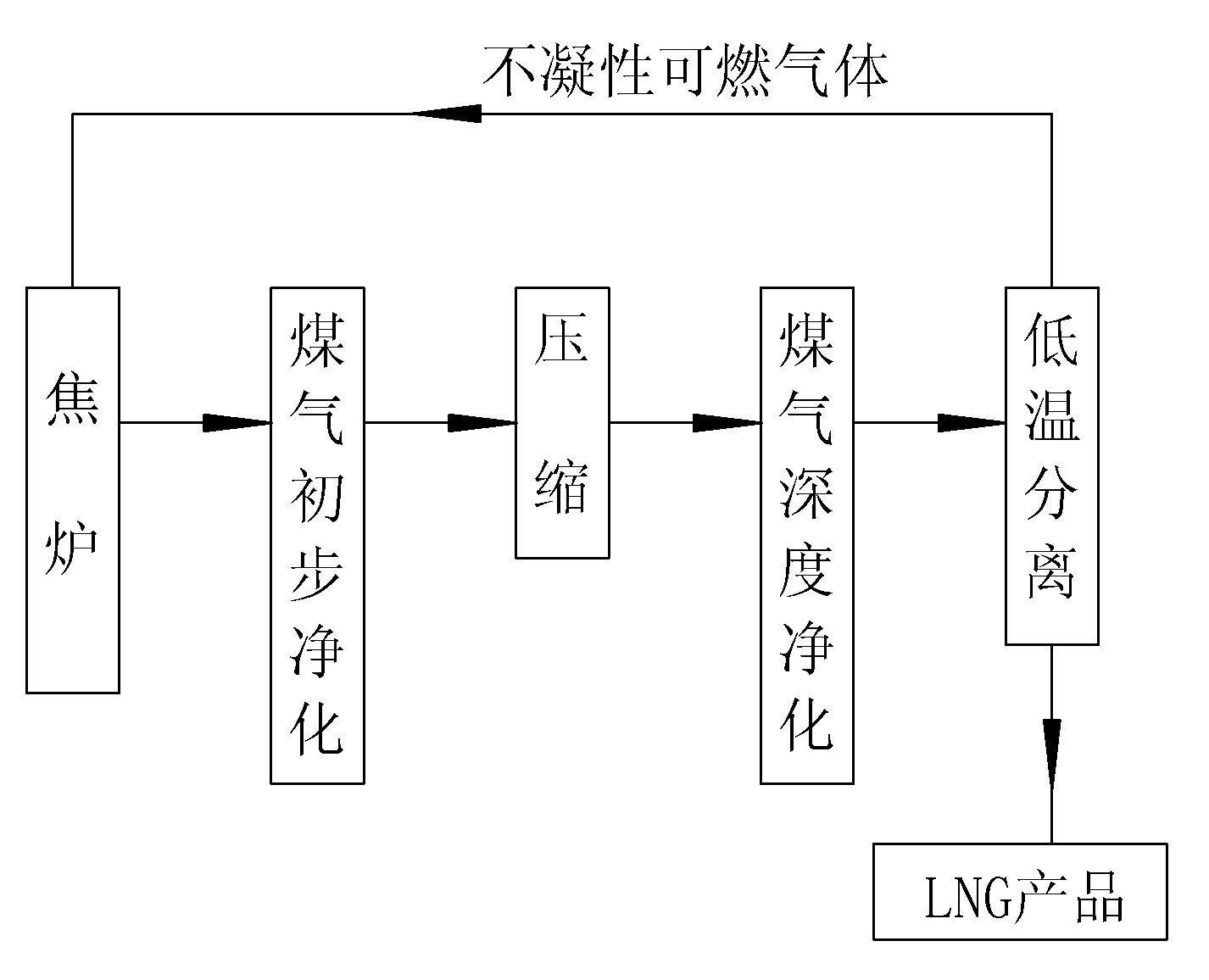

Process for purifying and liquefying coke oven gas

A coke oven gas and process technology, applied in the field of coke oven gas purification and liquefaction, can solve the problems of reducing investment and operating costs, environmental pollution, etc., and achieve the effects of reducing investment and operating costs, increasing corporate profits, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058]Coke oven gas is separated from gas and liquid to obtain crude gas at 75-95°C, which is cooled to 10-45°C in the primary cooler, and by-products such as condensed ammonia, tar, naphthalene, etc. are discharged; after primary cooling, the gas enters the electric trap, The by-products such as light tar and naphthalene are separated in the device; after the electric trap, the gas enters the debenzene tower, and the benzene and naphthalene in the gas are removed with washing oil, and the washing oil is recycled after distillation and regeneration; the gas after debenzene enters the blower, and the blower The gas is pressurized to 10-40kPa; the gas pressurized by the blower enters the deamination section, and the ammonia in the gas is absorbed by the mother liquor containing sulfuric acid to produce ammonium sulfate; the deamination gas enters the desulfurization section, and the iron oxide powder is used in the desulfurization section Suspension liquid method desulfurization,...

Embodiment 2

[0060] Coke oven gas is separated from gas and liquid to obtain crude gas at 75-95°C, which is cooled to 10-45°C in the primary cooler, and by-products such as condensed ammonia, tar, naphthalene, etc. are discharged; after primary cooling, the gas enters the electric trap, The by-products such as light tar and naphthalene are separated in the device; after the electric trap, the gas enters the debenzene tower, and the benzene and naphthalene in the gas are removed by washing oil, and the washing oil is recycled after distillation and regeneration; the gas after debenzene removal enters the deamination section , use mother liquor containing sulfuric acid to absorb ammonia in the gas to produce ammonium sulfate; after deammonization, the gas enters the desulfurization section. After the compressor is pressurized to 0.2-10MPa, it enters the final desulfurization section. The final desulfurization section uses iron oxide powder suspension liquid method to desulfurize, reducing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com