Diluting fuel-in-oil separating apparatus of internal combustion engine

a technology of internal combustion engine and separation apparatus, which is applied in the direction of mechanical equipment, lubricant mounting/connection, machines/engines, etc., can solve the problems of significant heat energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

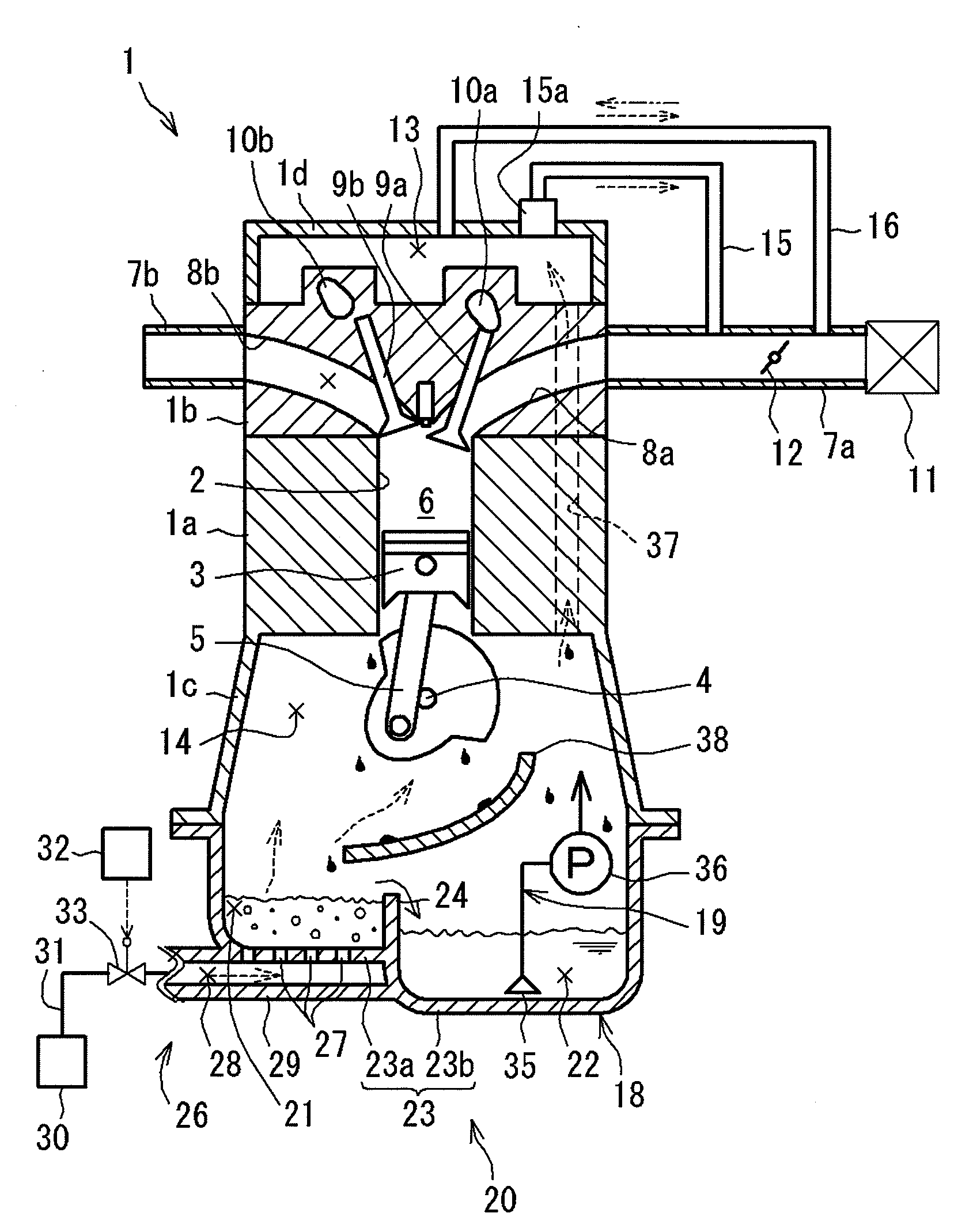

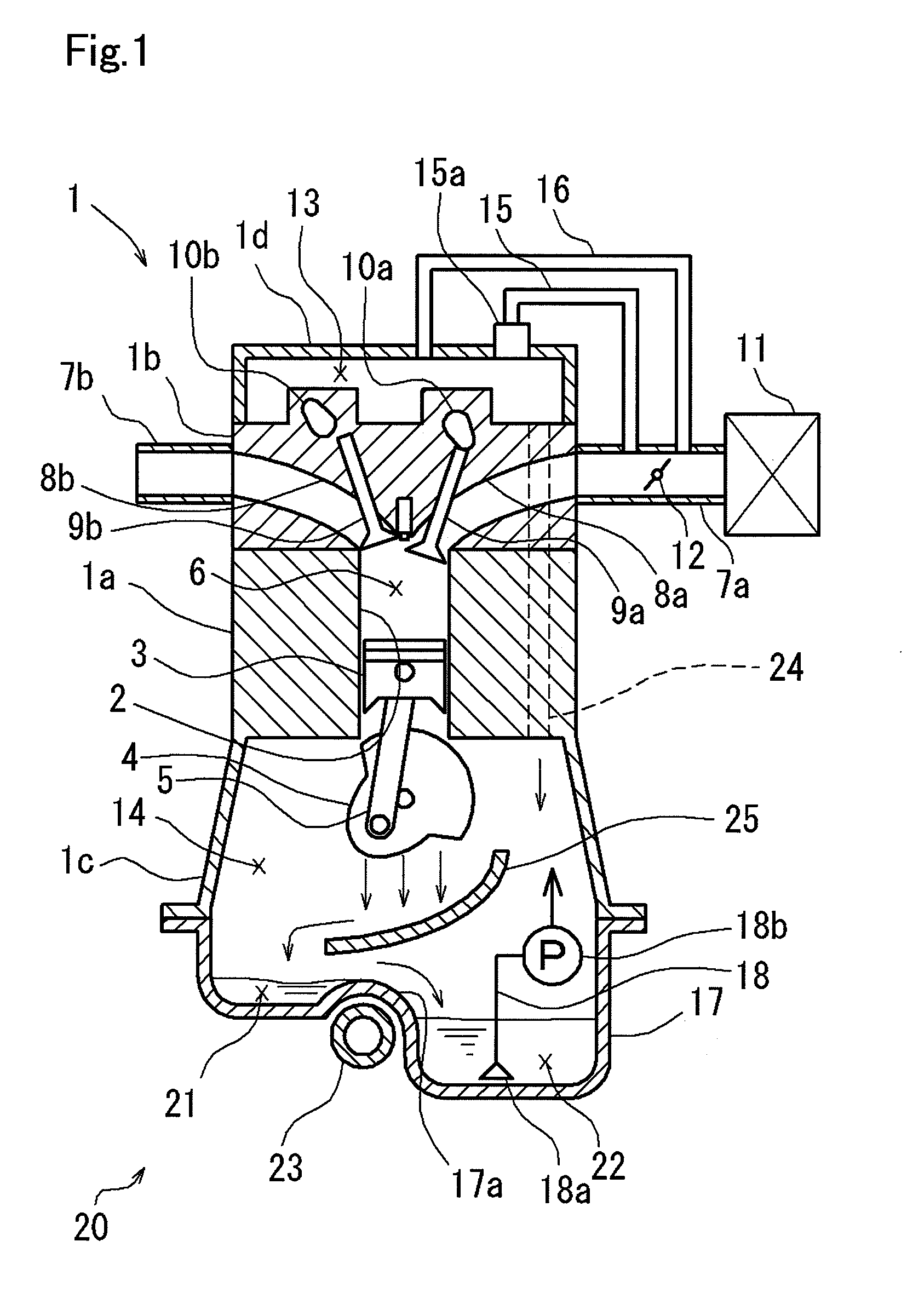

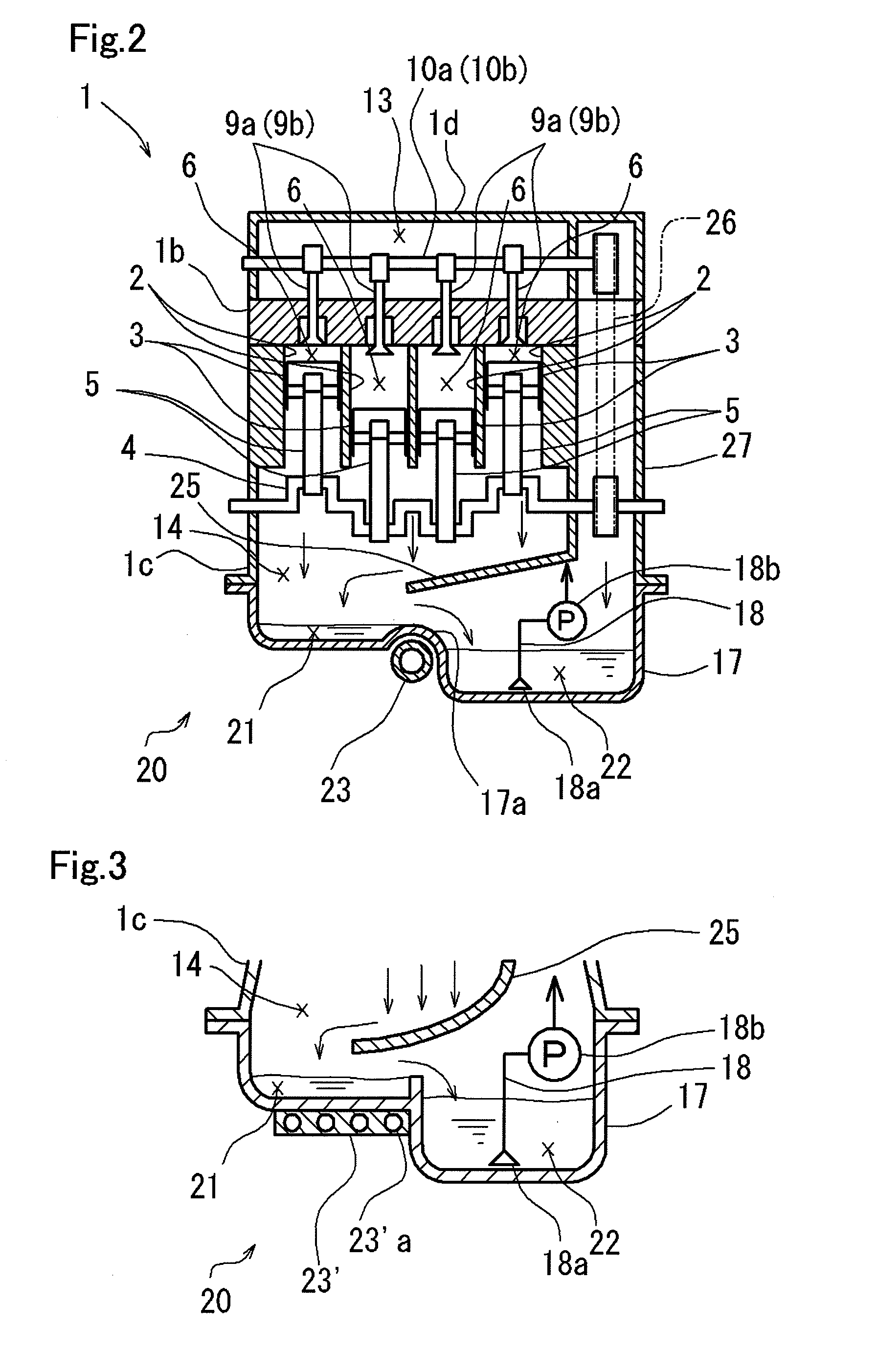

[0063]Hereinafter, first to third embodiments of the present invention will be described in detail with reference to the drawings. In the first to third embodiment, a cylinder injection type internal combustion engine is described as an example of an “internal combustion engine”according to the present invention, the cylinder injection type internal combustion engine performing a secondary injection before and after a primary injection.

[0064](1) Configuration of Engine

As shown in FIG. 1, an engine 1 according to the first embodiment includes a cylinder block 1a provided with a cylinder 2 and a cylinder head 1b fixed to an upper portion of the cylinder block 1a. A piston 3 is reciprocably supported inside the cylinder 2 of the cylinder block 1a. A crankcase 1c rotatably supporting a crankshaft 4 is fixed to a lower portion of the cylinder block 1a. The crankshaft 4 is connected to the piston 3 via a connecting rod 5. A combustion chamber 6 is provided above the piston 3, the combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com