Liquid filter construction and methods

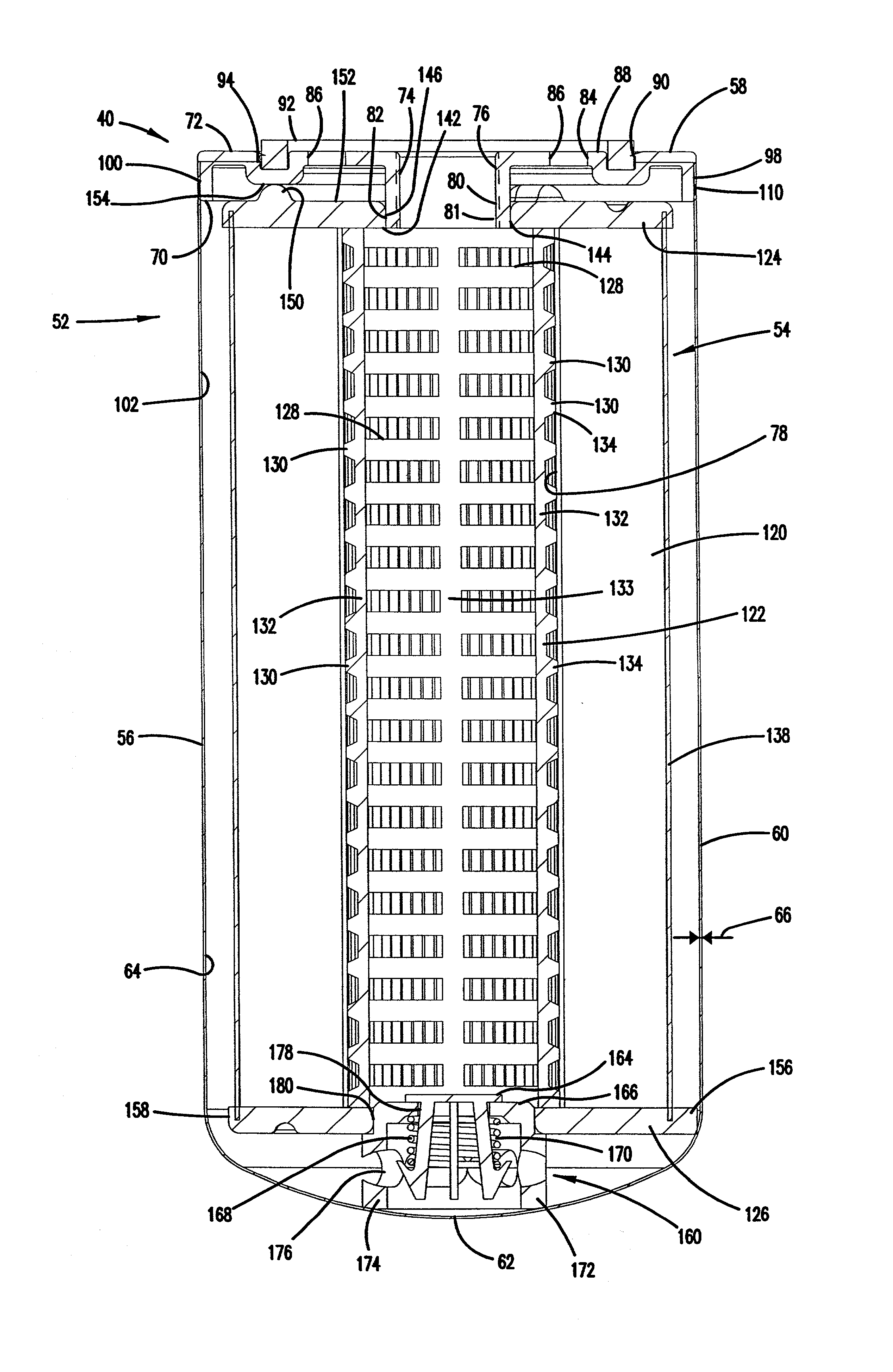

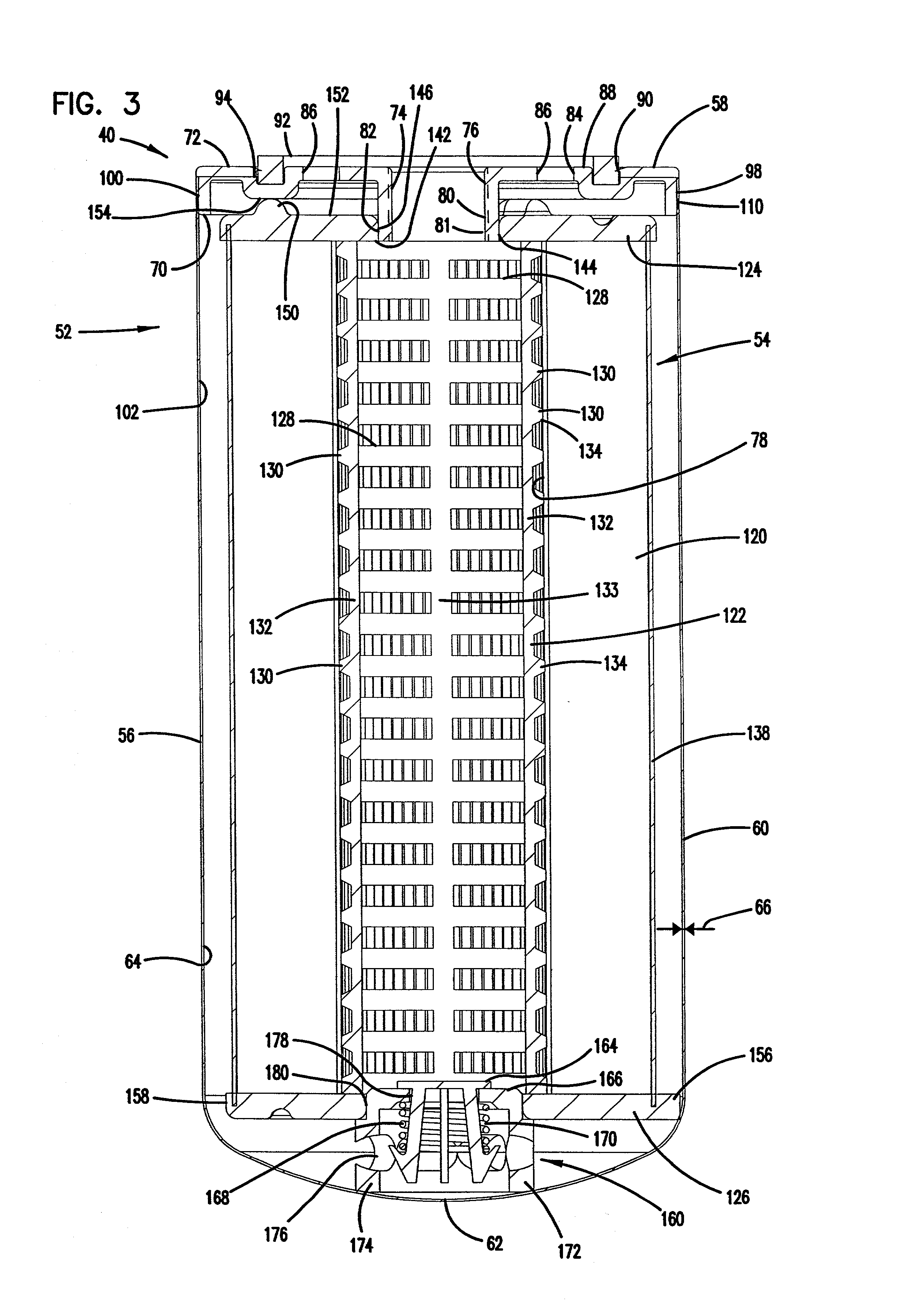

a technology of liquid filter and construction method, which is applied in the direction of filtration separation, lubricant mounting/connection, separation process, etc., can solve the problems of filter head not being spun off from the filter head, system strength not optimized, and failure typically occurring at the rolled lock joint, so as to improve burst strength and impulse fatigue strength, the effect of eliminating the use of a roll or lock seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

0 0 0 0 B 0 120 35-55 45 C 30 150 80-100 90 D 90 210 125-145 135 E 120 270 170-190 180 F 180 330 215-235 225 G 200 400 260-280 270 H 210 410 305-325 315 I 500 800 665-685 675 J 510 810 710-730 720

[0101] In general, it should be appreciated from the above discussion that the number of tacks applied between the baffle plate 58 and can 56 can vary between at least 1 tack, no more than about 16 tacks, and typically about 2-8 tacks. Preferably, the processes will have the tacks evenly spaced. In preferred processes, the tacks are formed by varying the power between a low power (on the order of 100 watts), up to a power sufficient to form a tack or spot weld at a fast enough speed (in these examples, at least 3 kW and a speed of at least 300 inches / minute, typically, at least 400 inches / minute). The power variance can be in the form of a saw-tooth wave, a square wave, a sine wave, and other such patterns. In preferred processes, after the plurality of stitches or tacks is applied, there w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com