Oil-based drilling cutting treatment method

A technology for oil-based drill cuttings and a treatment method, which is applied in the fields of petrochemical and petrochemical emissions treatment, can solve the problems of wasting oil resources, poor treatment effect, and environmental hidden dangers, and achieves reduction of operation and management costs and viscosity reduction effect. Good, improve the effect of recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Analysis of components of oil-based drilling cuttings

[0022] Referring to GB8929-2006 Distillation method for determination of water content in crude oil, use a distillation device with a moisture receiver to separate and measure the water content in oil-based cuttings; the content of mineral oil in oil-based cuttings is determined by soil petroleum infrared photometry (Draft for comments) Determination; the solid slag content in oil-based cuttings adopts the difference method, that is, the difference between the quality of cuttings and the quality of water and mineral oil. The composition content of oil-based drill cuttings in an oilfield is shown in Table 1.

Embodiment 2

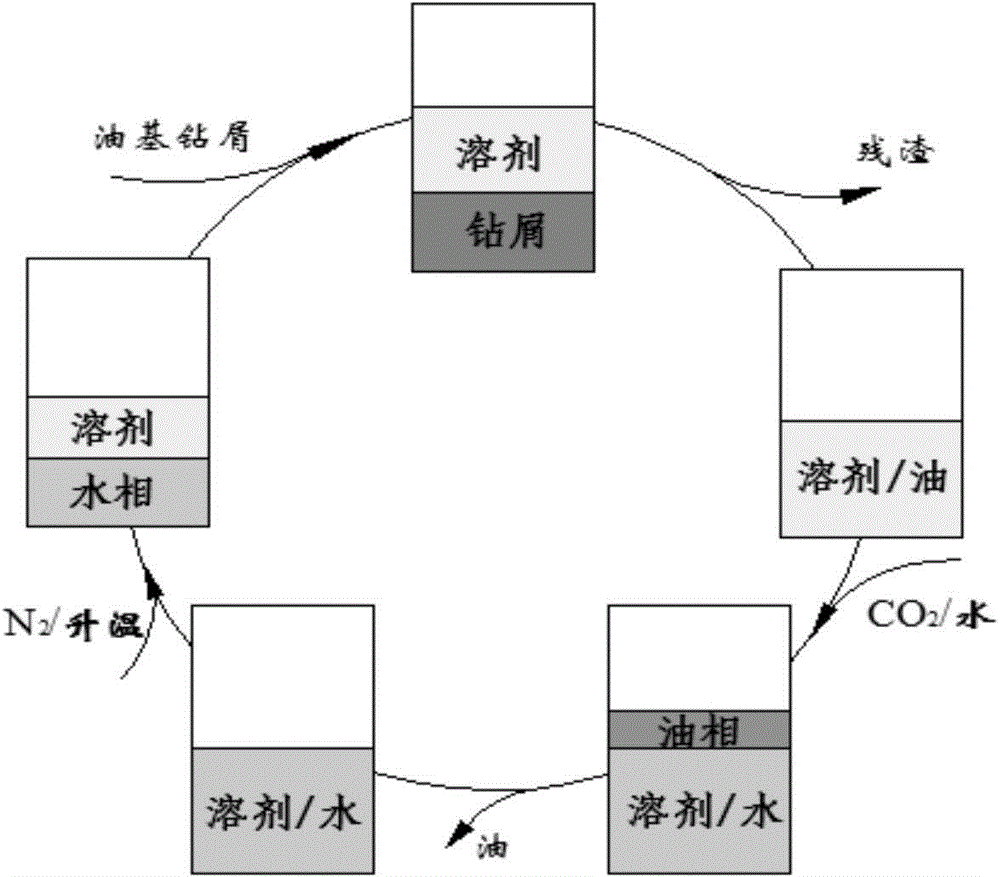

[0023] Example 2 Oil-based drill cuttings mineral oil extraction process

[0024] Take quantitative oil-based cuttings and add equal mass of on / off solvent CyNMe 2 , stirred at room temperature for 30 minutes, and centrifuged to separate the residue and liquid phase. After the residue was air-dried, the oil content of the solid residue was measured by infrared photometry. The measured oil content is shown in Table 2.

Embodiment 3

[0025] Embodiment 3 Separation and recovery of mineral oil process

[0026] Take a quantitative extract, add a quantitative amount of water according to the extract: water = 1:2 (vol%), and introduce CO under high-speed stirring. 2 , after aeration at 1L / min flux for 1h, the hydrophilicity of the on / off solvent is turned on, the solvent is transferred from the oil phase to the water phase, and the mineral oil is separated and recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com